The "Technological Contention" of Dexterous Hands Reaches Its Zenith

![]() 06/26 2025

06/26 2025

![]() 535

535

Editor's Note: The crux of whether robots can truly become "dexterous" lies in the final centimeter—dexterous hands. Integrating the essence of mechanics, sensors, and AI technology, they transcend the limitations of traditional grippers, evolving from mere industrial tools into autonomous "humanoid agents." Amidst the surge of embodied intelligence, dexterous hands have emerged as frontrunners.

Xinghe Frequency has curated a series of articles dedicated to dexterous hands, delving into the heart of this technological revolution centered around "touch," "manipulation," and "creation." We will not only spotlight the sophisticated technology behind the intricate joints but also delve into the profound thoughts on "ability boundaries" and "human-machine symbiosis" amidst this technological upheaval.

Together with our forward-thinking peers, we will explore the ultimate frontiers of human-machine collaboration achievable through these "dexterous hands."

Previous Articles:

Dexterous Hands, the "Last Centimeter" of Humanoid Robots

Four Rising Stars in Domestic Dexterous Hands

Author|Mao Xinru

Editor|Bai Xue

The world of dexterous hands has witnessed some recent drama.

Tesla filed a lawsuit against a former Optimus team engineer, accusing him of stealing information related to the "development of advanced robotic hand sensors" and subsequently establishing a competitive startup.

The engineer founded the robotics company Proception just six days after leaving Tesla and launched the dexterous hand ProHand five months later. With 22 degrees of freedom and a gripping force of 20 kilograms, its performance parameters are comparable to Tesla's products.

While it remains uncertain whether "technology was stolen," the speed at which a team of only nine individuals "launched a dexterous hand product within five months and delivered it within 15 months" seems remarkable.

This rapid development is a microcosm of the dexterous hand sector's rapid progress. As a crucial metric for gauging the upper limit of a robot's operational capabilities, with the burgeoning embodied intelligence trend, the dexterous hand sector is experiencing unprecedented growth.

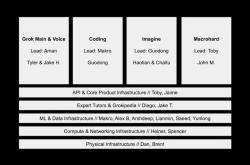

Currently, three types of players have entered this multi-billion-dollar competition: professional dexterous hand manufacturers, robot body manufacturers, and manufacturers capable of repurposing core hardware technologies.

Not only is the number of players in this sector increasing, but the financing market is also heating up. Lingxin Qiaoshou, which set a record for seed round financing in the dexterous hand sector, recently received additional investment from Ant Group, and Paxini Perception secured two rounds of funding exceeding 100 million yuan within 50 days.

Despite the growing popularity of dexterous hands, the investment community remains divided on their potential.

The core reason is that the current technological path of the dexterous hand industry has yet to converge, with multiple technological routes coexisting. There is no consensus within the industry on which technological route holds more advantages.

This uncertainty is particularly evident in the three key elements that form the core of dexterous hands—drive motors, transmission solutions, and sensors. Each sub-field presents a scenario of "contention among multiple schools of thought."

Drive Solutions: The Muscles of Dexterous Hands

In the construction of dexterous hands, drive solutions serve as the "core power source," akin to human muscle tissue providing power for hand movements. Their selection and optimization directly determine the performance boundaries and industrialization potential of dexterous hands.

Currently, the drive solutions for dexterous hands revolve primarily around four technological routes: motor drive, hydraulic drive, pneumatic drive, and shape memory alloy drive.

Among them, motor drive has emerged as the mainstream choice for industrialization due to its comprehensive advantages, including small size, fast response, convenient regulation, good stability, and high precision.

There are three main types of motors currently used in dexterous hands on the market: brushless DC motors, frameless torque motors, and coreless motors.

These three types exhibit significant differences in structural integrity, core performance emphases, and application focuses.

Brushless DC motors retain a complete motor structure and emphasize control precision, making them mostly used in general industrial automation.

Frameless torque motors have a special design, retaining only core components and pursuing high torque density, making them suitable for highly integrated robots.

Coreless motors feature an ironless core structure, focusing on response speed and lightweight, with energy conversion efficiency generally exceeding 85%, making them ideal for dynamic operating scenarios.

As actuators for delicate operations, dexterous hands require high dynamic response and higher power density. Therefore, coreless motors are currently the primary choice for electrical drive solutions in dexterous hands.

Depending on the commutation method, coreless motors can be divided into brushed coreless motors and brushless coreless motors. Brushed motors have a rotor without an iron core, while brushless motors have a stator without an iron core.

The image shows Moons' products, with the brushed coreless motor on the left and the brushless coreless motor on the right.

Brushed coreless motors are suitable for industries with high requirements for product sensitivity and reliability.

Brushless coreless motors are ideal for applications requiring long-term continuous operation and high control or reliability. From a development trend perspective, the future will likely lean towards the use of brushless coreless motors.

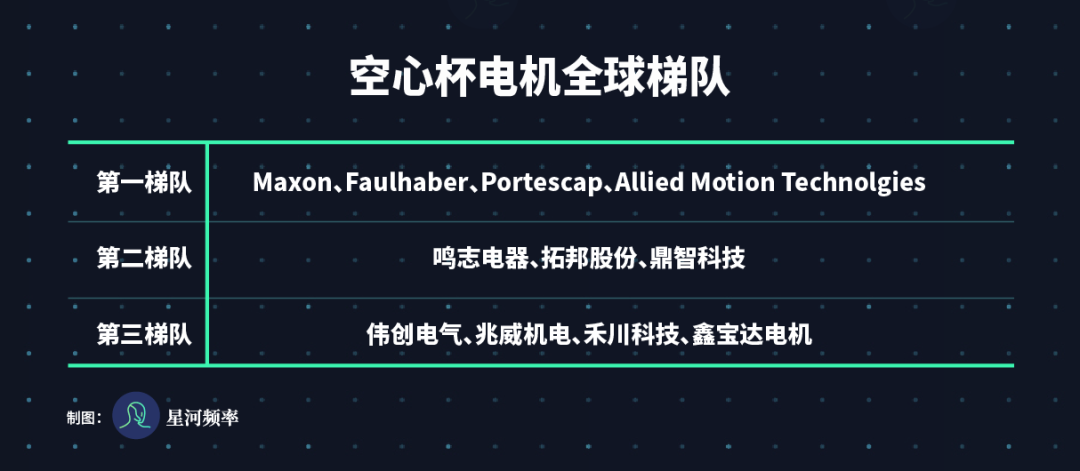

Currently, the high-end coreless motor market is still dominated by European enterprises, with domestic leading enterprises striving to promote domestic substitution, with Moons being a notable representative.

By acquiring companies in the United States and Switzerland, Moons began researching and developing coreless motors in 2015.

Currently, there are two major core technological barriers in the field of coreless motors: winding design and technology, and winding equipment issues.

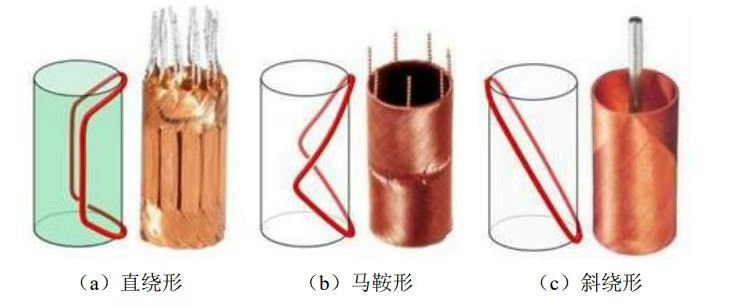

Winding design is crucial in determining whether a motor can be miniaturized while ensuring efficiency and output. The mainstream methods are straight winding, saddle winding, and oblique winding. The straight winding process is relatively complex, and domestic and foreign manufacturers mostly adopt the latter two methods.

Industry leaders like Maxon from Switzerland use saddle winding, and Faulhaber from Germany uses oblique winding, but the process details are strictly confidential.

Moons chose the most challenging straight winding method and developed a new patent to compensate for the original deficiencies of the process. Its product performance is comparable to overseas competitors, and the price is at least 1000 yuan lower under the requirements of humanoid robots.

Moreover, the wire winding equipment also determines the precision and efficiency of its products. Production technologies are primarily divided into manual winding, winding, and one-time molding. Currently, domestic manufacturers mostly adopt the winding method, while overseas manufacturers mainly adopt one-time molding.

To achieve product consistency, long lifespan, and mass production, it is necessary to rely on automated production lines and advanced winding equipment.

However, Maxon and Faulhaber's automated production equipment is self-developed and not sold externally.

Moons chose an "indirect tactic," first introducing Japanese equipment to accumulate process data and gradually developing its own research. Currently, it adopts a semi-automatic production method and is catching up with the foreign rework rate of 0.05%.

Currently, Moons' coreless motors are priced between 1200 and 2300 yuan, showing a trend of domestic substitution compared to Maxon's price of approximately 4000 yuan in Switzerland. According to relevant institutional research, the price is expected to fall below 1000 yuan after large-scale mass production.

Transmission Solutions: The Ligaments and Bones of Dexterous Hands

The transmission system in dexterous hands undertakes the dual functions of power transmission and structural support, similar to how human ligaments connect bones and transmit muscle force.

As dexterous hands evolve towards higher load-bearing capacity and precision, transmission technology is undergoing a paradigm shift from a single mode to a composite system.

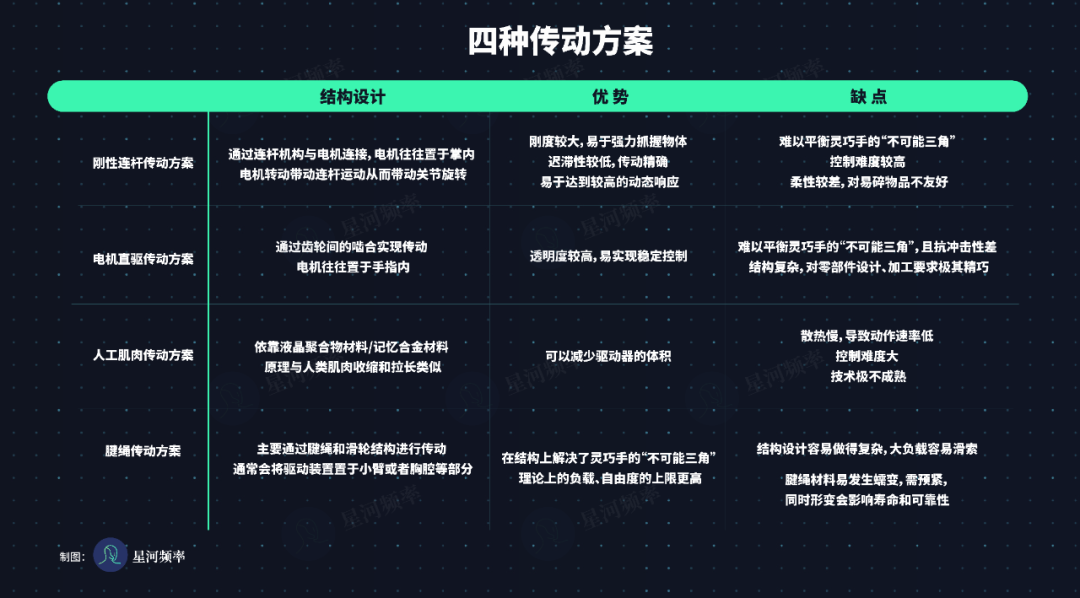

Currently, there are four mainstream transmission solutions: rigid link transmission, motor direct drive transmission, artificial muscle transmission, and tendon transmission.

The core difference among these four solutions lies in how they balance and maximize the "impossible triangle" of "cost-system parameters-stability" of dexterous hands. The most mainstream methods are tendon transmission solutions and composite transmission solutions of "tendon+."

In fact, early multi-finger dexterous hands mostly adopted link transmission solutions. To better balance the "impossible triangle" and make the transmission solution more flexible and space-saving, the tendon transmission solution emerged.

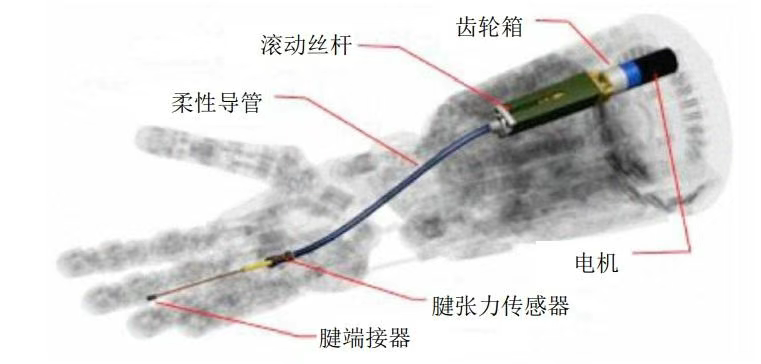

Its drive devices are mostly placed in parts such as the forearm or chest cavity, and the transmission is primarily carried out through tendon and pulley structures, to a certain extent simulating the human hand tendon structure.

Since drive devices such as motors and reducers are no longer placed within the palm, the tendon transmission solution structurally resolves the "impossible triangle," and theoretically, the upper limits of load and degrees of freedom of tendon transmission are also higher.

For example, the Shadow dexterous hand launched by Shadow Robot in the UK adopts a tendon transmission solution. It is one of the mature dexterous hand products that have achieved mass production and is considered one of the world's most advanced five-finger robotic hands.

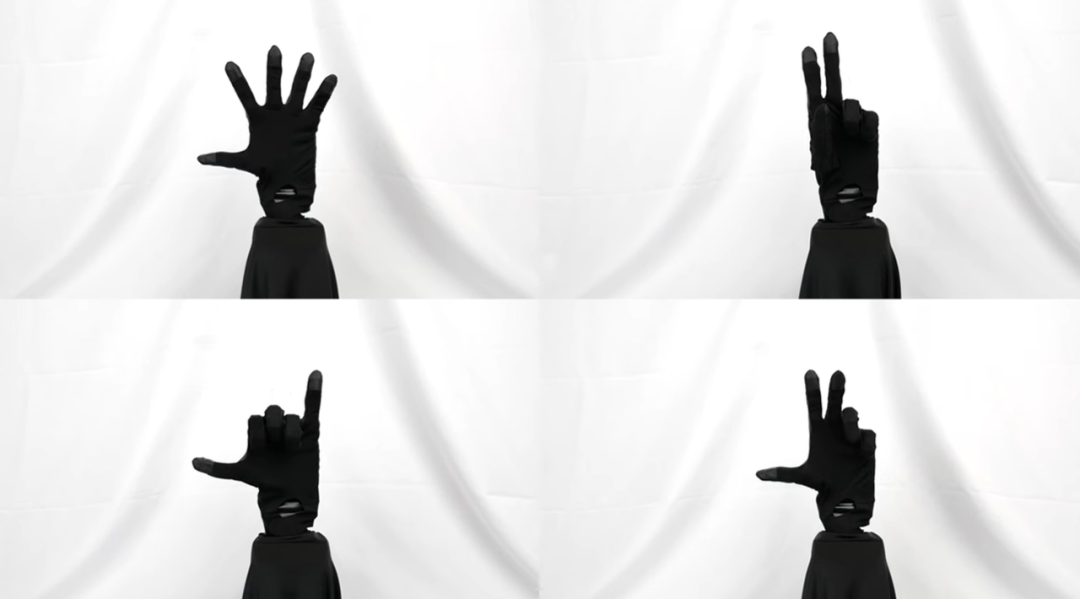

Its dexterous hand has 24 joints and 20 independently controllable degrees of freedom, designed and developed based on human hand movements. It can perform actions similar to human hands and is comparable to human hands in force output and sensitivity.

To compensate for the deficiencies of the tendon transmission solution in rigidity, load capacity, and precision, the composite transmission solution of "tendon+" is gradually being adopted by major manufacturers.

For example, Tesla's Optimus' third-generation dexterous hand uses a "tendon+direct drive" solution, while domestic companies like Lingxin Qiaoshou adopt a "tendon+link transmission" solution.

Optimus' third-generation dexterous hand adopts a three-stage transmission solution of "planetary gearbox+planetary roller screw+tendon," achieving a balance between high precision and flexible force control. Its 22 degrees of freedom are close to those of human hands, allowing Optimus to perform fine movements such as abduction and adduction in addition to the original flexion and extension movements.

This hybrid solution, combining rigid and flexible transmission, optimizes the balance between load and flexibility, improving Optimus' operational efficiency in grasping irregular objects and performing complex assembly tasks, enabling it to achieve dynamic grasping such as catching tennis balls and complex operations such as folding shirts.

Lingxin Qiaoshou is the only domestic company capable of simultaneously commercializing and mass-producing dexterous hands with link structures and tendon structures. Its research version, Linker Hand, adopts a "tendon+link" solution with 42 degrees of freedom.

The link structure is responsible for basic joint drive, ensuring stability and load capacity, while the tendon structure is used for fingertip and interphalangeal joints, enhancing flexibility and anthropomorphism.

Each finger can independently achieve 9 degrees of freedom motion control and is equipped with a 360-degree freely rotating full-drive design. It can not only complete high-difficulty actions such as pencil spinning and walnut rotating but also has a load capacity of 5kg, exceeding the limit of human fingers.

It is worth mentioning that motor direct drive and link transmission still offer high performance and reliability due to mature supply chains and experience accumulated in the industrial field. The choice of transmission solution depends on the specific application scenario.

Drive and transmission solutions form the internal structure of dexterous hands, yet to achieve intricate perception and manipulation of the external world, sensors are indispensable. They function akin to the synergistic effects of human skin and the nervous system.

Sensors: The Sensory and Neural Nexus of Dexterous Hands

The sensor system is the cornerstone for dexterous hands to achieve intelligent operation. Just as human skin senses touch, temperature, and pressure, and the nervous system transmits these signals for response, sensors play a similar role in robotic hands.

Dexterous hands employ both internal and external sensors.

Internal sensors primarily provide feedback on the hands' posture, encompassing motion and force sensors. They offer joint angle, position, and dynamic information, ensuring the stability of the hands.

External sensors, such as proximity and tactile sensors, primarily detect the position, force, and other attributes of target objects.

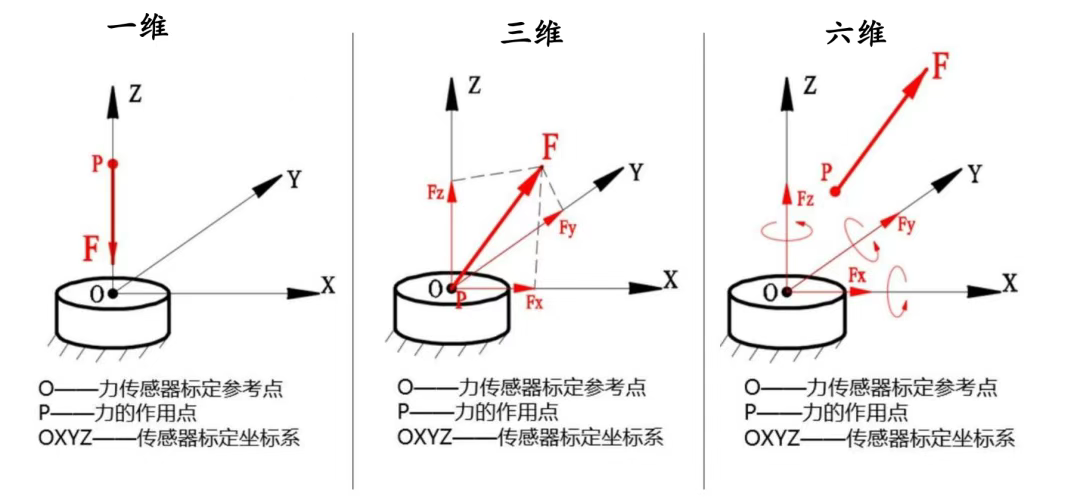

Force sensors capture the torsional torque on rotating or non-rotating mechanical components with precision, converting these physical parameters into electrical signals recognizable by the system. This provides essential data for robotic force feedback.

In the 2024 Implementation Opinions on Promoting Innovation in Future Industries issued by the Ministry of Industry and Information Technology, six-axis force sensors were highlighted as key technologies for future manufacturing and intelligent sensing.

Technically, different force sensors have varied application scenarios. Six-axis force sensors transcend the limitations of one-dimensional and three-dimensional sensors, analyzing composite force/torque information in any direction and at any point within a three-dimensional space. This comprehensive sensing capability makes them the preferred choice for complex interaction scenarios.

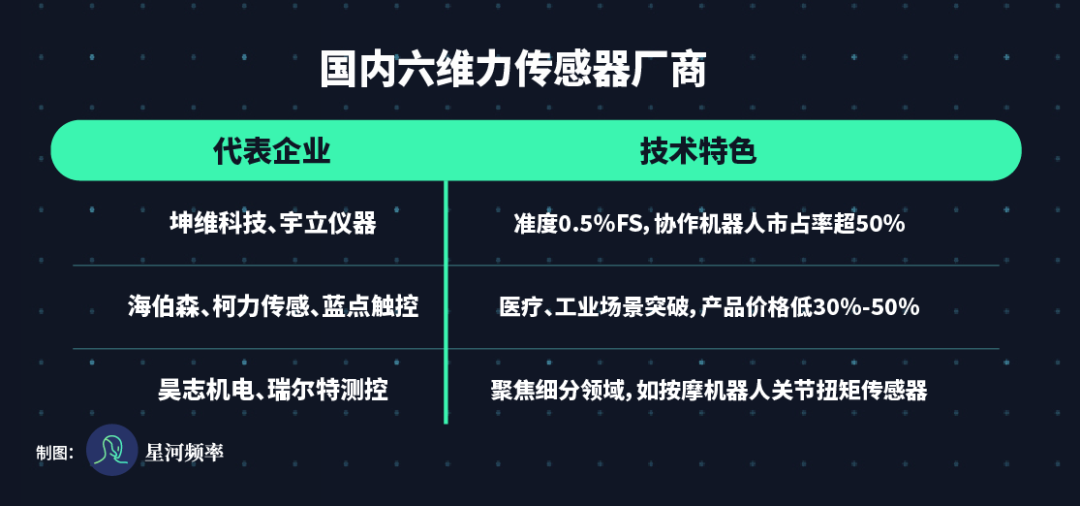

Kunwei Technology, a leading domestic manufacturer of six-axis force sensors, boasts a compact design with a broad measurement range, robust overload resistance, and customizable high precision. These sensors have been applied to Tesla's Optimus, enabling precise force perception and adjustment, facilitating complex tasks like handling and assembly, and significantly enhancing task quality and efficiency.

Currently, domestic six-axis force sensors have transitioned from "laboratory catch-up" to "industrial substitution." However, breaking into high-end markets necessitates collaborative innovation in materials, algorithms, and ecosystems.

Tactile sensors are crucial for robots to perceive and interact with their surroundings with greater finesse and accuracy.

They operate through a conversion chain of "physical signal-electrical signal-digital signal." This involves capturing physical parameters like contact force and temperature using flexible sensitive materials, converting them into current and voltage waveforms, processing them through digital circuits, and finally decoding them into recognizable tactile data.

Tactile sensor development has evolved through three stages: initially measuring only fingertip force, progressing to multi-array tactile sensing, and now achieving multi-modal, multi-region tactile perception.

Tactile sensors come in both flexible and rigid varieties. Rigid sensors emphasize high-precision local force feedback, while flexible sensors can cover the entire body, sensing multi-dimensional information like pressure and temperature. Currently, flexible tactile sensors dominate the market.

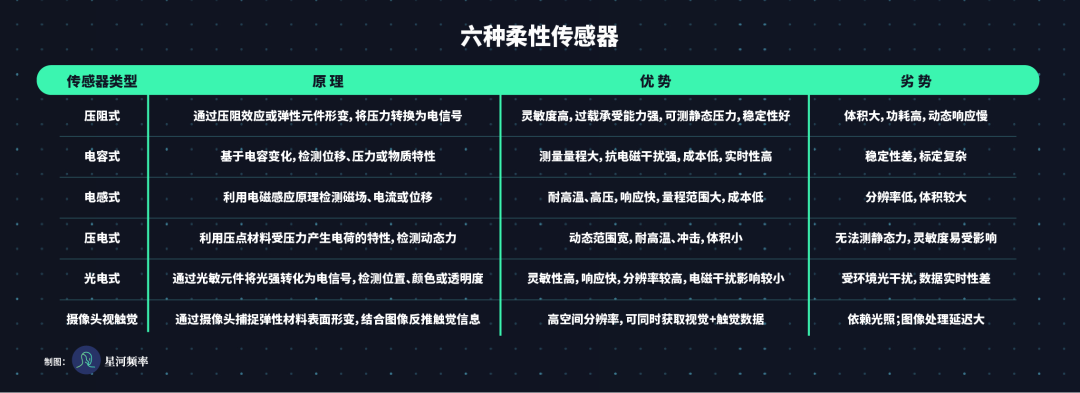

Based on different principles, flexible sensors are further categorized into six types, including capacitive, inductive, and piezoresistive sensors. Currently, piezoresistive sensors are relatively mainstream.

Among current dexterous hand players, Pacinian Perception and Daimeng Robotics stand out with unique advantages in sensor technology.

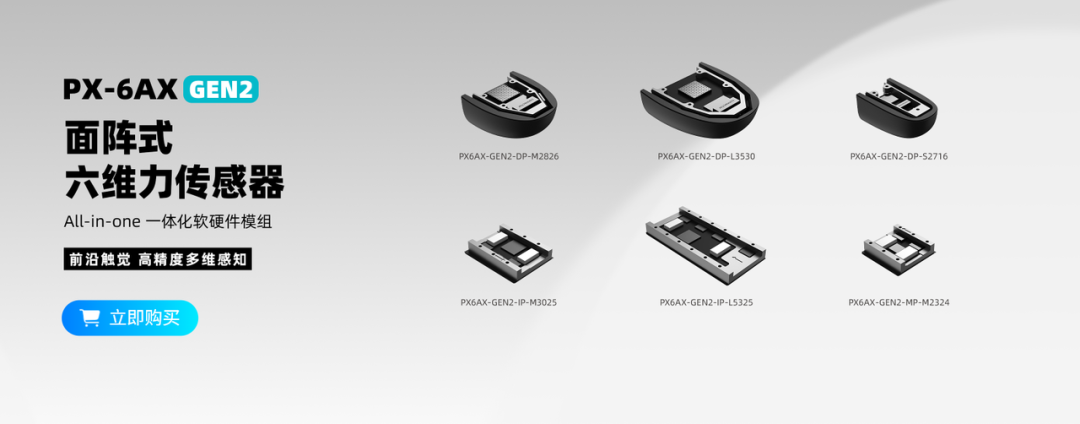

Pacinian specializes in 6D Hall array-based multi-dimensional tactile sensing and embodied intelligence core technologies, achieving independent and controllable high-precision multi-dimensional tactile sensors and mass production. Their multi-dimensional array tactile sensor is currently the only flexible mechanical sensor capable of obtaining highly consistent physical interaction data.

Daimeng Robotics' core research focuses on visual-tactile sensors. In April this year, they released the world's first multi-dimensional high-resolution high-frequency visual-tactile sensor, DM-Tac W, which integrates a camera into the sensor and captures various modal information such as shape, texture, softness, slippage, pressing force, and tangential force of objects during contact through an ultra-high-density sensing array.

Furthermore, the often-discussed "electronic skin" falls under the category of flexible tactile sensors. Leading domestic players in this field include Hanwei Technology, Fly New Materials, and Hongxin Electronics.

Diverse opinions and vigorous development characterize this domain. The differentiation and fusion of technical routes, coupled with competition and innovation among manufacturers, signify that this crucial component, embodying the "fingertip dream" of embodied intelligence, is accelerating towards the fast lane.

Who will ultimately emerge victorious in this technological landscape will determine the depth and breadth of future robots' "hands" in grasping the world.