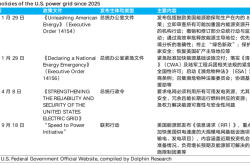

"Unlucky Year" for Tesla: Is It Heading Towards Mediocrity?

![]() 07/24 2024

07/24 2024

![]() 597

597

Introduction

Drawing pie-in-the-sky promises alone is futile when it comes to solving problems.

How can one concisely express the bossiness of capitalists towards their subordinates?

In the classic style of the internet community's "six-word mantra" – "Do it if you want, leave if you don't!"

Combining this classic phrase with a more avant-garde expression, we have the recent popular variant: "If you don't do it, there's always someone else who will." But remember, this must be said in a flat, emotionless tone to achieve the maximum psychological intimidation of employees.

This year, Elon Musk has delivered such messages to his subordinates numerous times, especially to the team responsible for the 4680 battery cells, which has been repeatedly reprimanded by the CEO since May.

While Musk has not explicitly stated what the consequences will be if targets are not met, in leaked internal emails, we should not underestimate his current deterrent power over his subordinates. After all, from mid-April to mid-June this year, Tesla laid off over 15,000 employees globally, with the 4680 battery cell team experiencing a quarter of its staff cut, including Drew Baglino, the senior vice president in charge of the project.

Image | Drew Baglino, who had been with Tesla for 18 years before announcing his resignation on April 15th, long served as Senior Vice President of Powertrain and Energy Operations.

According to internal sources, the team size has dropped to around 800 people. The entire project has now been handed over to Karn Budhiraj, Senior Vice President of Global Supply Chain. Meanwhile, Musk has explicitly instructed the team to "fundamentally resolve the issue of yield rates" by the end of the year and to further reduce production costs.

Of course, the battery team's troubles are not the only issue that has Musk invoking the "someone else" mantra. The delays in the so-called Robotaxi project are another headache, though this project itself has a whiff of artificially manufacturing new positives after the initial wave of good news.

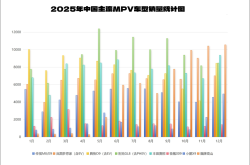

The Dilemma of Dry Process

The problems encountered by Tesla in producing its own 4680 battery cells have been covered in more than one article recently, from various angles. Therefore, we will not repeat the previously mentioned issues of heat dissipation and yield rates.

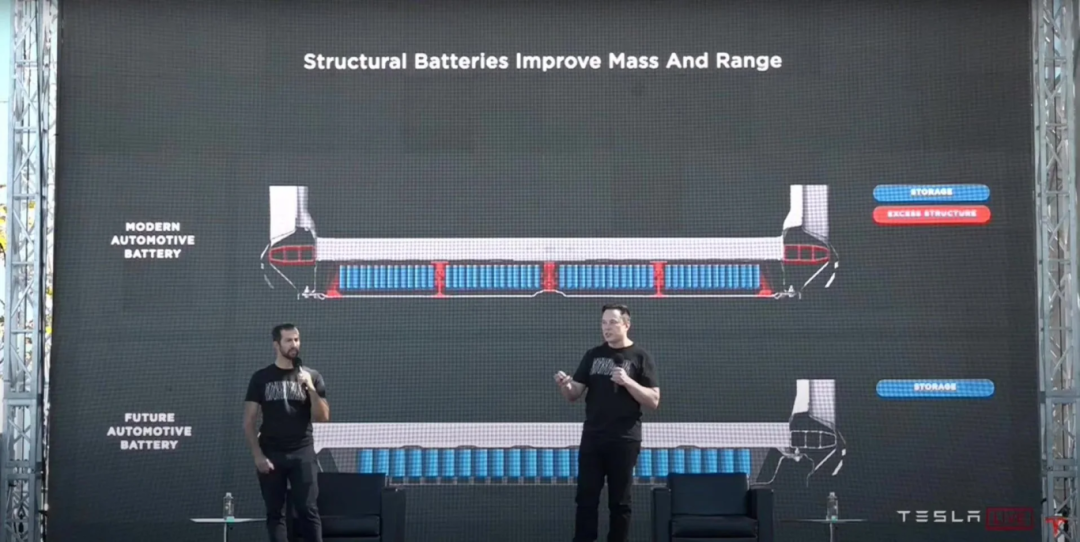

At the beginning of this year, Tesla started delivering Cybertruck equipped with its own 4680 battery cells. While we all know that this is a "downgraded" version with a monthly production of around 5 million cells due to technical issues, it is still far from what Musk promised four years ago in his PPT. However, knowing the gap is one thing; understanding the specific challenges Tesla faces with the 4680 cells has remained elusive to the outside world.

Image | On the left is Karn Budhiraj. Notice the background showing the difference between 2170 and 4680 battery cells in a vehicle's battery pack.

But with Baglino's departure and Budhiraj taking over, various revelations from laid-off employees have gradually shed light on the issue. The crux of the problem lies in the dry electrode process – the very core technology that Musk proudly touted at the 4680 battery cell launch four years ago.

Dry electrode technology is a departure from traditional processes. In traditional battery electrode production, factories need to apply a chemical coating onto electrode foils, which must then be thoroughly dried before rolling the final cells. This drying process is extremely time-consuming, and during this period, flammable and explosive toxic solvents in the coating slurry must be recovered and disposed of.

The emergence of the "dry" process not only gave the traditional "wet" process its new name but also made its value immediately apparent.

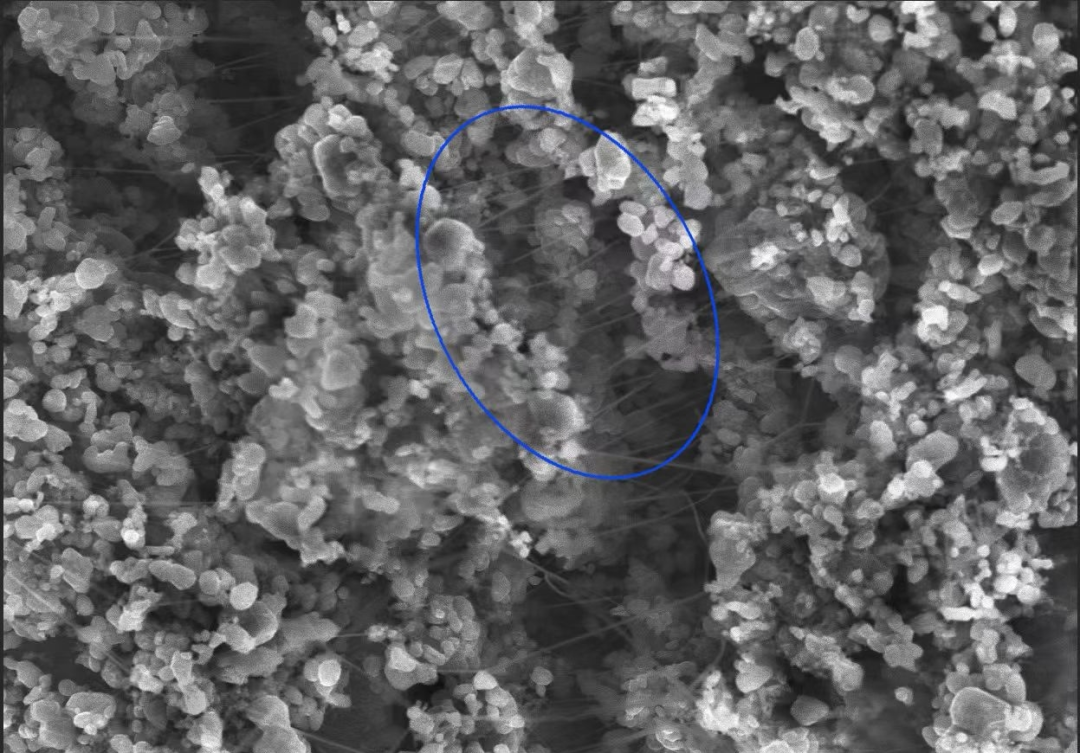

Image | Electrode processed using the dry process under an electron microscope, with the fibrillated binder circled.

The advantage of the dry process lies in its use of no solvents. It directly mixes the multi-component dry powder particles that make up the electrode at high speeds, fibrillates the binder through high-speed shearing, then hot-rolls the mixed powder to form a self-supporting film, which is finally pressed with the current collector to form the final lithium-ion battery electrode.

The dry process eliminates the slurry mixing, coating, and drying steps of the wet process. This not only significantly increases production efficiency but also shortens the production line length by 70%. It also has excellent environmental benefits. This is why Tesla was able to attract a new wave of capital frenzy after the 4680 battery cells were announced.

Tesla's dry process technology comes from its acquisition of Maxwell Technologies, Inc. However, only the negative electrode of the 4680 battery cells currently utilizes this technology, which has limited significance in cost reduction and production efficiency improvements. Currently, the positive electrode is still sourced from LG Energy Solution and two Chinese battery companies located in Jiangsu and Zhejiang through wet process finished products.

It is reported that Tesla had already produced dry positive electrode rolls in its lab at the end of 2022 but "failed to mass produce due to technical misjudgments." New rumors claim that after Baglino's departure at the end of April, Tesla quickly adjusted its technical roadmap, and "dry positive electrode mass production is making breakthroughs"...

Image | Part of the 4680 production line inside Tesla's Gigafactory Texas, as shown in an official Tesla photo.

Does it feel like Tesla's empire will usher in a new era of glory after the "villain" is gone?

New Troubles for Robotaxi

Any Tesla electric vehicle owner who has opted for the FSD (Full Self-Driving) feature can participate in Tesla's Robotaxi program.

With just a tap on the Tesla app, the vehicle joins the fleet and starts earning money when the owner is away. Owners can flexibly choose to join or leave the Robotaxi fleet as needed. As a result, the monthly earnings from the vehicle far exceed its operating costs, while Tesla takes a share of the profits.

Image | Imagine half of the existing Tesla vehicles in the US being deployed for autonomous operations... Wow!

At last month's Tesla shareholder meeting, Elon Musk unveiled this "new pie" by announcing the official launch date. Of course, this was just the announced date, as Musk, well-versed in stock price manipulation, had already been at work since April.

As early as April 6th, Musk announced on his social media platform X that over $10 billion would be invested by the end of 2024 to enhance training computation power, maintain massive data uplink and downlink channels, and provide Tesla's servers with vast storage capacity for video data.

When asked about the purpose of these investments, he ambiguously suggested that Robotaxi could be one of the main application directions.

After interacting with fans, he finally dropped the pretense and announced, "Tesla Robotaxi unveil on 8/8" (Tesla's Robotaxi service will be launched on August 8th).

However, subsequent events are well-known. In the second week of July, insider information leaked that the Robotaxi launch would be delayed until October. Last Tuesday, Musk confirmed this news on his X profile, citing the need to modify some important designs and that "the extra time will allow us (Tesla) to show more."

For vehicles already produced and delivered to owners, there's likely nothing that can be modified unless they are recalled for retrofitting. So perhaps the remark referred to system or functional aspects. One thing is certain: the Robotaxi service will be delayed until this fall. Whether it will be further delayed in October remains to be seen.

As things stand, people are gradually realizing some crucial information. Firstly, despite brief mentions in books like "Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic Future," there has never been much specific detail about the Robotaxi project. And the only thing that was once certain – the project's name – has now been overturned.

Image | In a nutshell – if a Tesla owner applies for the Robotaxi service and sends their car out as a "driver," who is responsible if the vehicle causes fatalities, injuries, or even just damage in an accident?

Earlier this year, a Tesla executive revealed in an interview that the company's autonomous taxi project was officially named "Cybercab," with an operating model that allows FS-D-equipped car owners to send their vehicles out to earn money, similar to a combination of Airbnb and Uber.

It was a great name, fitting well with another product, the Cybertruck. But now, even Musk himself refers to it as Robotaxi. What then of the Cybercab project name?

Whether called Robotaxi or Cybercab, the core feature of Tesla's service lies in its use of the FS-D system to function as a "driver." The idea of sending your car out to earn money while you're at work is undoubtedly cool from any angle. However, there's a fundamental question: is the FS-D system reliable yet?

The FS-D V12.4.3 update released on the 11th of this month enhanced the ability to recognize gestures from pedestrians and simple temporary traffic signs, receiving "extremely high praise" like previous versions.

But the fundamental issue remains: when will it truly advance from L2 to even L3 "conditional autonomy," let alone achieving the full promise of Full Self-Driving. Without true autonomy, how can you send your car out as a "driver" while you sit in your office or at home?

Image | "Are you also a driver?"

Considering the current measures employed by domestic competitors like AutoX, Tesla might develop a remote control terminal costing tens of thousands of dollars, requiring Robotaxi service participants to be on standby at all times. The distinction between "autonomous driving" and "driverless" is almost irrelevant at this point.

In summary, despite Musk's boast at the June shareholder meeting that Robotaxi will bring $5 to $10 trillion in growth for Tesla, given the readily observable example of AutoX, this claim may not even qualify as a "pie-in-the-sky promise" under current technical conditions; it's more like empty talk.

From last year's stock price issues to this year's layoffs and growth far below expectations. Besides the struggling 4680 battery cell project, the mega casting project is a complete bust. After five years of smooth sailing following its 2018 turnaround through the establishment of a wholly-owned factory in China, Musk and Tesla seem to have fallen back into troubled waters.

Of course, compared to the life-or-death situation Tesla faced in 2017-2018, the current situation of exhausted technological dividends, potential user fatigue, and stagnant growth can only be considered minor setbacks. We can treat it as Tesla or Musk's "unlucky year."

Image | Frankly, the Robotaxi project reeks of overly ambitious profit promises. It's creating news where there is none.

In fact, aside from the highly unreliable and overly ambitious Robotaxi project, which promises massive growth, Tesla's technicians still have a chance to meet Musk's deadline in addressing the 4680 battery cell issue.

However, the problem is that after a four-year delay, even if both positive and negative electrodes adopt the dry process, Tesla's self-produced 4680 battery cells have lost their technological lead. Competitors like CATL have already produced products with equivalent or even slightly superior technology and performance.

But this is the norm in business and even global competition. Typically, no one expects to "wipe out" all competitors and achieve ultimate victory by relying on a single ahead-of-its-time technology, especially when competitors are at a similar technological level.

Tesla is not in survival crisis; the company is merely showing signs of mediocrity. But this is precisely what Musk may be most reluctant to face.