Li Bin and Lei Jun Sound the Alarm: The Chip Crisis is Back Again

![]() 01/28 2026

01/28 2026

![]() 492

492

Lead

Introduction

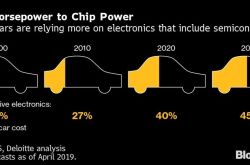

The most affected are smart electric vehicle companies that are highly reliant on advanced chips.

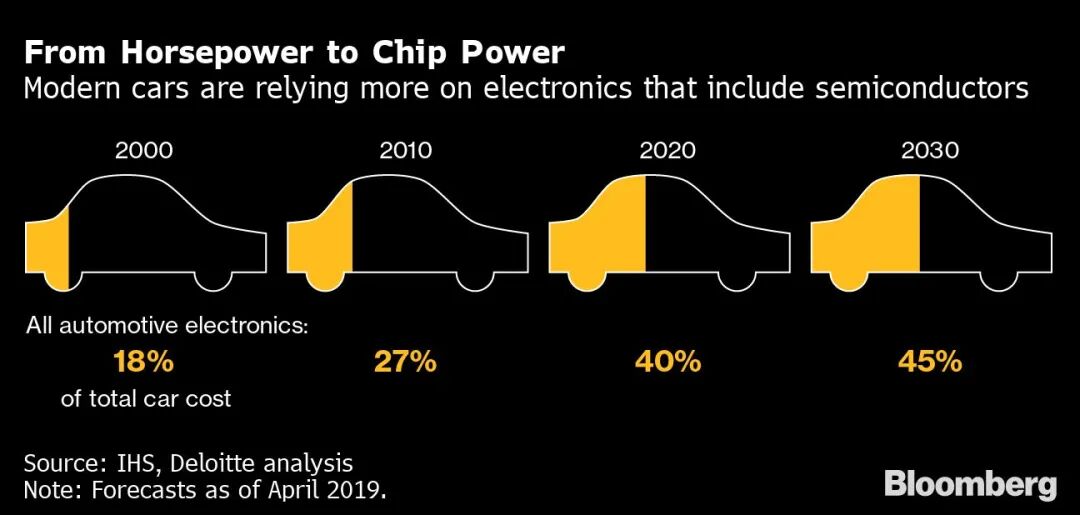

With the rapid development of artificial intelligence technology, the global demand for high-performance memory chips in data centers has exploded. Now, this trend is triggering a supply chain crisis that is affecting the automotive manufacturing industry.

Recently, several analyst firms including Wells Fargo, UBS, and S&P Global have issued consecutive warnings, pointing out that due to the persistent tight supply of DRAM (Dynamic Random Access Memory) chips, automakers may face severe cost pressures and production disruption risks as early as 2026.

The root of this crisis lies in the fact that chip manufacturers are prioritizing production capacity allocation to the more profitable and faster-growing data center and artificial intelligence markets. The automotive industry, which accounts for less than 10% of the global DRAM market, has weak bargaining power.

Currently, DRAM prices have seen astonishing increases. According to a Wells Fargo report, the spot price of DDR5 is more than eight times higher than the 2024 average, while DDR4 prices are more than 16 times higher.

Although the current DRAM cost per vehicle is only about $50 to $110, the dual pressures of price hikes and supply shortages could significantly squeeze automakers' profit margins, especially for electric vehicles and high-end models that rely heavily on chips.

Analysts predict that global DRAM demand will grow by about 26% in 2026, while supply will only increase by about 21%, indicating a supply gap of around 14%. Meanwhile, major chip suppliers including Micron, Samsung, and SK Hynix are accelerating their shift in production capacity towards high-bandwidth memory (HBM) and other high-end products, further reducing the chip sources for the automotive industry.

Although this crisis shares some similarities with the chip shortage in 2021, its driving factors are more concentrated. The expansion of artificial intelligence infrastructure is reshaping the global semiconductor supply chain landscape. Automakers not only need to cope with soaring prices but may also face production line shutdowns due to chip supply disruptions.

01 AI Demand Squeezes Automotive Industry

In fact, as early as December last year, Meng Qingpeng, Vice President of Supply Chain at Li Auto, admitted, 'In 2026, the automotive industry will face an unprecedented storage chip supply crisis, with a fulfillment rate possibly below 50%.'. Subsequently, Li Bin, the founder of NIO, stated in early January this year that the current memory price hikes pose significant pressure on the automotive industry.

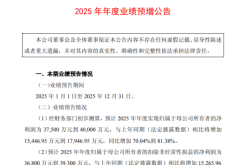

During a livestream in January, Lei Jun, Chairman of Xiaomi Auto, also mentioned the price of the new Xiaomi SU7, stating, 'Memory prices are now rising on a quarterly basis. They increased by 40% to 50% last quarter and are expected to continue rising in the first quarter. At this trend, the memory cost for vehicles alone will increase by several thousand yuan this year.'

In reality, the core contradiction of the current DRAM supply chain tension stems from the resource competition between the explosive growth in demand for artificial intelligence data centers and the steady increase in chip demand from the automotive industry.

With the popularization of generative AI applications like ChatGPT, tech giants such as Google, Meta, and Amazon have seen a surge in demand for high-bandwidth memory (HBM) and high-end DRAM. The profit margins for these chips are significantly higher than those of traditional DRAM products used in the automotive industry.

As a result, the three giants—Samsung, SK Hynix, and Micron—have significantly shifted their capital expenditures and production capacity towards data centers, even gradually phasing out older process chips like DDR4 that are still widely used by automakers. S&P Global pointed out that this capacity shift is not a temporary adjustment but a structural transformation, as the profitability and growth prospects of AI data centers far exceed those of the automotive market.

The automotive industry is at a double disadvantage in this competition. Firstly, it has a small market share, accounting for less than 10% of global DRAM demand, making it difficult to compete with tech companies that often order hundreds of thousands of wafers in procurement bargaining. Secondly, it lags in technology. Due to long certification cycles and high reliability requirements, the automotive industry often adopts chip processes that are one to two generations behind consumer electronics.

Now, as chip manufacturers accelerate the phase-out of old production lines in pursuit of higher profits, automakers are forced into a dilemma where the supply of old chips decreases while the production capacity for new chips is insufficient.

Wells Fargo estimates that by 2025, the top ten automotive Tier 1 suppliers will consume about 54% of the global automotive DRAM, with BYD, Tesla, and Aptiv leading the pack. This means that the supply chain risks are more concentrated among leading enterprises.

Furthermore, data on the supply gap further confirms the urgency of the crisis. Wells Fargo predicts a 26% increase in DRAM demand in 2026, while supply will only increase by 21%. UBS points out that some automotive chip prices have already risen by more than 100%.

More severely, capacity expansion takes time. IBK Securities analysis states that new factories from Samsung and SK Hynix will not achieve mass production until 2028, making it difficult to alleviate the supply tension before then. Additionally, the shortage of memory chips is spreading from consumer electronics to the automotive sector, as all industries share the same basic silicon wafer production capacity.

S&P Global warns that the time window for automakers to redesign systems and secure supplies is narrowing. If adjustments are not made in time, production disruptions may occur from 2026 to 2028.

This shortage also differs keyly from the 2021 chip crisis, which was triggered by multiple factors including supply chain disruptions caused by the pandemic, front-loaded demand for consumer electronics, and a rebound in automotive demand. The current crisis is more focused on memory chips and has a single, clear driving factor: the artificial intelligence investment boom.

This means that the solution is no longer just waiting for capacity recovery but requires the automotive industry to reevaluate its chip strategy, including technological upgrades, supply chain reshaping, and even deep collaboration with chip manufacturers.

02 How Should Automakers Respond?

It is evident that the impact of this round of memory chip shortages on the automotive industry will be diverse. The first to bear the brunt is cost pressure. Although the current DRAM cost per vehicle is less than $200, S&P Global expects new contract prices to increase by 70% to 100% year-on-year in 2026. High-end models, equipped with more autonomous driving and entertainment systems, may see chip costs per vehicle reach as high as $2,000.

It is difficult for all of this additional cost to be passed on to consumers, especially in the current fierce price competition for electric vehicles. Manufacturers' profits will be significantly squeezed. Wells Fargo points out that signs of panic buying have already emerged, which may drive up prices and disrupt production plans, forming a vicious cycle.

Another issue is the risk of production disruptions. UBS warns that shortages may interfere with global automotive production as early as the second quarter of this year. The most affected will be electric vehicle manufacturers that are highly reliant on advanced chips, such as Tesla, Rivian, and BYD, as their models have higher digitalization and greater memory demands. Traditional automakers like Ford and General Motors will be less affected, but high-end models also face challenges.

Upstream Tier 1 suppliers in the supply chain are also not immune. Companies like Visteon and Aptiv, which primarily provide high-tech cockpit and driving assistance systems, will experience direct order delivery delays due to chip shortages. If chip supply remains tight, the possibility of some models being discontinued from 2026 to 2027 is not alarmist.

To cope with the crisis, the automotive industry can seek solutions through both short-term relief and long-term transformation. Short-term strategies include securing supplies, adjusting configurations, and cost shifting. Some automakers have already attempted to sign long-term agreements with chip manufacturers, but the effects have been limited as production capacity priority still leans towards data centers. Dealers may alleviate pressure by simplifying configurations and extending delivery times.

In the long term, the automotive industry must accelerate technological iteration and supply chain autonomy. For example, Tesla has independently developed AI chips and maintains close cooperation with NVIDIA; BYD has also ventured into chip production, although its products are currently relatively basic. More automakers may be forced to redesign electronic architectures to reduce reliance on single chips or shift to more advanced processes like DDR5, but this requires time and significant investment.

It can be said that this crisis reveals the deep-seated vulnerability of the automotive supply chain. With the advent of the software-defined vehicle era, chips have transformed from ordinary components into strategic resources. In the future, automakers may need to become more deeply involved in chip design, invest in chip production capacity, or establish equity-level cooperation with suppliers.

S&P Global suggests that the automotive industry should establish a more flexible supply system while promoting chip standardization to reduce reliance on specific models. For consumers, when purchasing vehicles in the coming years, they may face reduced options, longer waiting times, and even price increases, especially for models with high-end technological configurations.

In conclusion, the memory chip shortage triggered by artificial intelligence is pushing the automotive industry into a new round of supply chain turmoil. This crisis is not just about costs and production but forces the industry to rethink its position in the global semiconductor ecosystem.

Those companies that can quickly adapt and proactively deploy chip strategies may gain a greater competitive advantage after the crisis, while those that respond slowly may face the risk of being eliminated. In this era where chips are the core competitiveness, the transformation of the automotive manufacturing industry is destined to be full of challenges.

Editor-in-Chief: Cui Liwen Editor: He Zengrong

THE END