Can the Industry's Conscience Regarding the "375kg Payload" Standard Be Upheld?

![]() 06/16 2025

06/16 2025

![]() 569

569

It is hoped that the issues raised by the 375kg payload will not merely be the tip of the iceberg.

As the price war intensifies, many consumers believe they can enjoy quality products at lower prices, but is this truly the case?

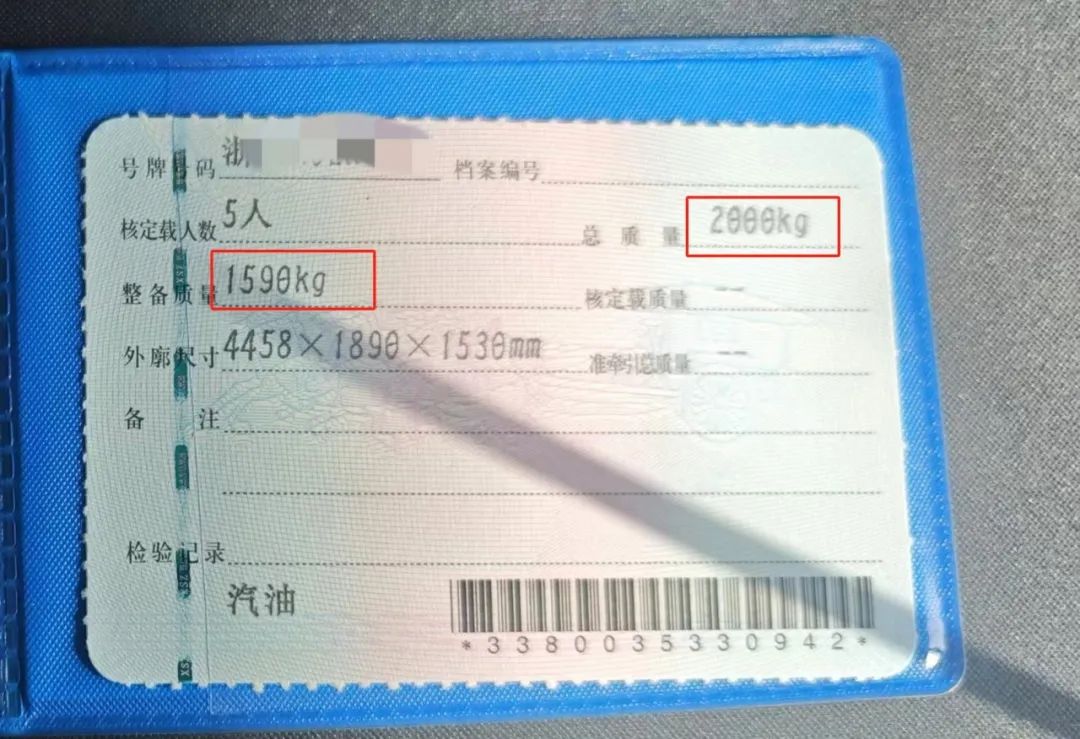

Recently, users have discovered that the effective payload of newly purchased vehicle models is significantly low, with many 5-seater models boasting an effective payload of only 375kg. Slightly heavier individuals may exceed this payload limit even when only four people are seated.

When confronted with these concerns, automakers justify their production by claiming compliance with national standards.

So, how did this seemingly unreasonable data become a national standard, and is there any rationale behind it?

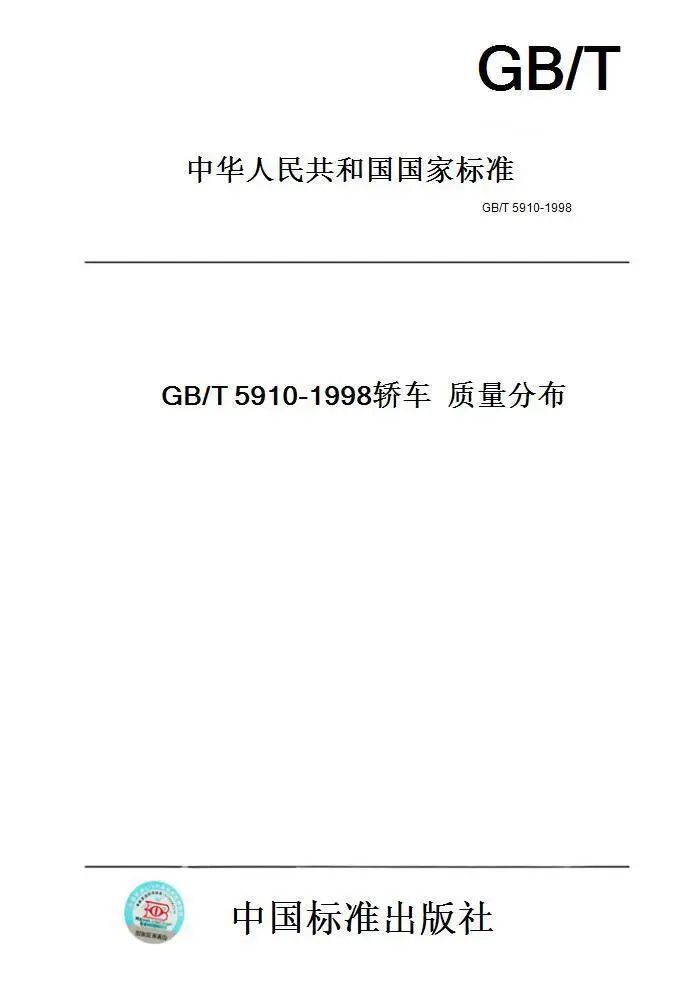

Regarding vehicle payload standards, the currently enforced national standard is defined in the "Automobile Mass Distribution." It sets the standard mass for one passenger at 68kg and the luggage per person at 7kg, translating to a minimum effective payload standard of 75kg per seat.

However, this compliant production is merely the minimum standard stipulated by the national guidelines, representing the bare minimum for a vehicle's payload design. Reaching 75kg per seat is nothing more than a passing grade.

Under the influence of the price war, this passing grade has become the only standard, especially for new energy vehicles, which have designed their weight around this value.

According to the National Health Commission's statistics, the average weight of adult males in China in 2020 was 69.6kg, an increase of 3.4kg compared to 2015. It is predicted that the obesity and overweight rates among adults in China will continue to rise.

Evidently, there is a significant mismatch between the current automobile manufacturing standards and the changes in China's average body weight.

Behind this mismatch lies a serious lag in standard setting. The "Automobile Mass Distribution" standard has been in effect since 1998, over 27 years ago. During this period, the increase in average body weight has far exceeded the projections of that time, rendering the standard severely outdated.

The national standard provides a minimum benchmark, and with the standard lagging behind, automakers have greater autonomy and can fully optimize vehicle performance based on market changes.

Why, after so many years and advancements in materials science and other technologies, has the design standard for automobile effective payload remained stagnant?

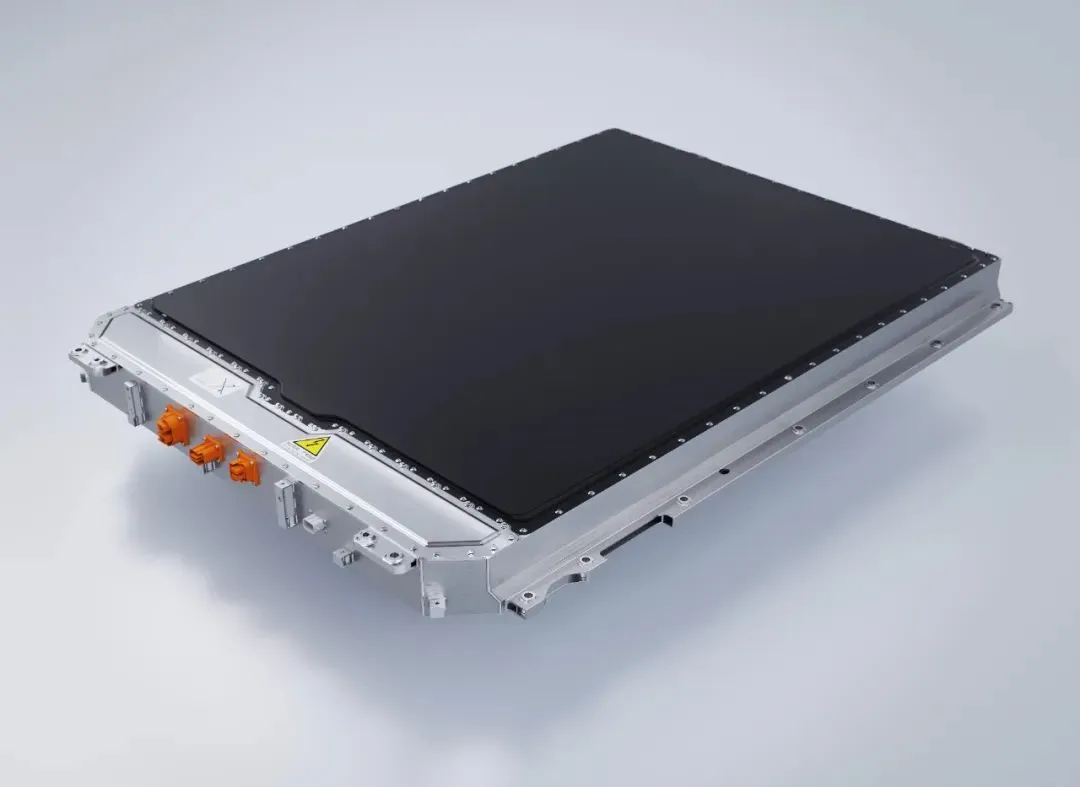

The root of this issue lies in the new energy transition. The most significant design change brought about by new energy vehicles is a substantial increase in the overall vehicle weight. A conventional 70kWh lithium iron phosphate battery pack weighs over 500kg. When considering the accompanying cooling system, management module, and external structure, the total weight may exceed 600kg.

And this is with noticeable advancements in battery technology. Earlier battery packs were even heavier.

More importantly, with the increase in overall vehicle weight, all design standards for new energy vehicles need to be optimized. According to calculations, for every 100kg increase in vehicle payload capacity, the frame rigidity needs to be strengthened by about 15%, and the manufacturing cost per vehicle will increase by 200-500 yuan.

These factors force automakers to be resourceful with effective payload, producing vehicles according to the minimum standards to minimize the increase in design costs caused by battery packs, but this is a precarious balancing act.

As a result, users may be operating their vehicles at or even beyond their load-bearing limits, especially for passenger vehicles. Traffic management departments only supervise the number of passengers and do not specifically verify the actual weight.

According to data from testing institutions, under full load conditions, the deformation of the vehicle's A-pillar will increase by 40% after a collision, and the airbag deployment will be delayed by 0.3 seconds, posing a serious safety risk.

It can be said that outdated standards have already compromised automobile safety.

Currently, many automakers advertise the maximum payload based on the minimum standard, but insiders reveal that most automakers do so deliberately, engaging in "reverse false labeling" to cope with collision tests.

Before 2024, C-NCAP allowed lightweight test vehicles to participate. Some automakers exploited this loophole, achieving excellent collision results under light load conditions, but the results of the 375kg full-load test were disastrous, with the A-pillar deformation exceeding the standard by 40%.

After 2024, C-NCAP improved the collision test by requiring vehicles to be tested under full load. Automakers can only obtain better collision results by falsely reporting the vehicle payload.

Of course, reverse false labeling of payload is not limited to achieving good results in collision tests. For almost all automobile tests, falsely labeled weight can gain extra points in test results.

For instance, in endurance tests, a lower payload can achieve better endurance results. Tests show that every 100kg reduction has an impact of about 30 kilometers on endurance. The endurance bonus gained by reducing weight is far more effective than automakers shaving off 0.1Cd in the drag coefficient.

Besides endurance, in vehicle acceleration tests and braking distance tests, a lower vehicle weight also offers advantages, making acceleration performance appear better and braking distances shorter.

Most importantly, this practice of false labeling seems to have become an industry norm. A blogger has counted that among the 4,500 passenger vehicles on the market at the end of 2024, over 30% of the models were advertised based on the minimum payload standard.

In the current landscape of intensifying internal competition within the automotive industry, automakers claim at press conferences that they have saved manufacturing costs through technological innovation, procurement integration, etc., and that the price war is to pass on benefits to consumers.

However, in reality, appealing data is often obtained through "unfair means." The metrics that new energy consumers care about, such as endurance and energy consumption, are embellished, and even collision test results are questionable.

As the automotive market continuously eliminates competitors through price wars, consumers need to be more vigilant. We cannot expect every consumer to meticulously verify every parameter like a professional engineer. We can only rely on national standards to ensure consumer safety.

Just like when the national football team loses a game, there is a head coach to take responsibility. However, the current state of the automotive industry is that outdated testing standards have made the competition lack impartial judges, ultimately leaving consumers to bear the responsibility themselves.

The essence of the payload parameter game is the trade-off between safety redundancy and cost-effectiveness. When automakers use the "mathematical game" of 375kg to exchange for testing benefits, families on real roads have long surpassed this fragile boundary. Only by prioritizing "safety redundancy" over "test-taking skills" can this dangerous numerical deception be ended.

Recently, many automakers' executives have publicly opposed internal competition but have not proposed clear solutions on how to address it.

Given the current situation, it might be prudent to first improve the overall advancement of the automotive industry by reforming those outdated standards in vehicle design. So-called industry self-discipline should not involve everyone silently adopting the minimum standards for declaration but should involve jointly promoting related technologies towards better outcomes.

For the parameter of vehicle effective payload, the most important step is undoubtedly to raise the minimum standard to a value that aligns with observable reality. Additionally, weighted scores should be introduced for tests of different payloads, so that automakers that invest more cost can gain more recognition.

Particularly, the endurance of new energy vehicles currently focuses solely on energy consumption, ignoring the impact of the overall vehicle weight, which is overly test-oriented.

As China's new energy automotive industry gradually goes global, forming a reasonable set of new energy vehicle design and evaluation systems is crucial. Especially when we have gained a manufacturing lead, setting standards becomes even more urgent.

Any competition carries the risk of getting out of control. Only by delineating boundaries with institutional or even legal norms can we prevent the situation from deviating.

Note: Some images are sourced from the internet. If there is any infringement, please contact us for deletion.