Revolutionizing Humanoid Robot Joints with GaN Technology

![]() 07/22 2025

07/22 2025

![]() 597

597

Produced by Zhineng Zhixin

As humanoid robots evolve from concept to reality, the power system emerges as a pivotal bottleneck, crucial for precise control and high-density integration. Gallium Nitride (GaN), a third-generation semiconductor technology, is swiftly replacing traditional silicon-based devices in servo control systems due to its exceptional attributes: high frequency, low loss, compact size, and high control accuracy.

Particularly in the drive of humanoid robot joints, module integration, and overall energy consumption control, GaN proves invaluable, serving as a cornerstone of the "power nerve." Let's delve into the pivotal role of GaN technology in robot joint drive, examining typical design implementations and illustrating how it fuels the kinetic energy of the next-generation humanoid intelligent agents.

Part 1: Addressing Servo Joint Needs with GaN

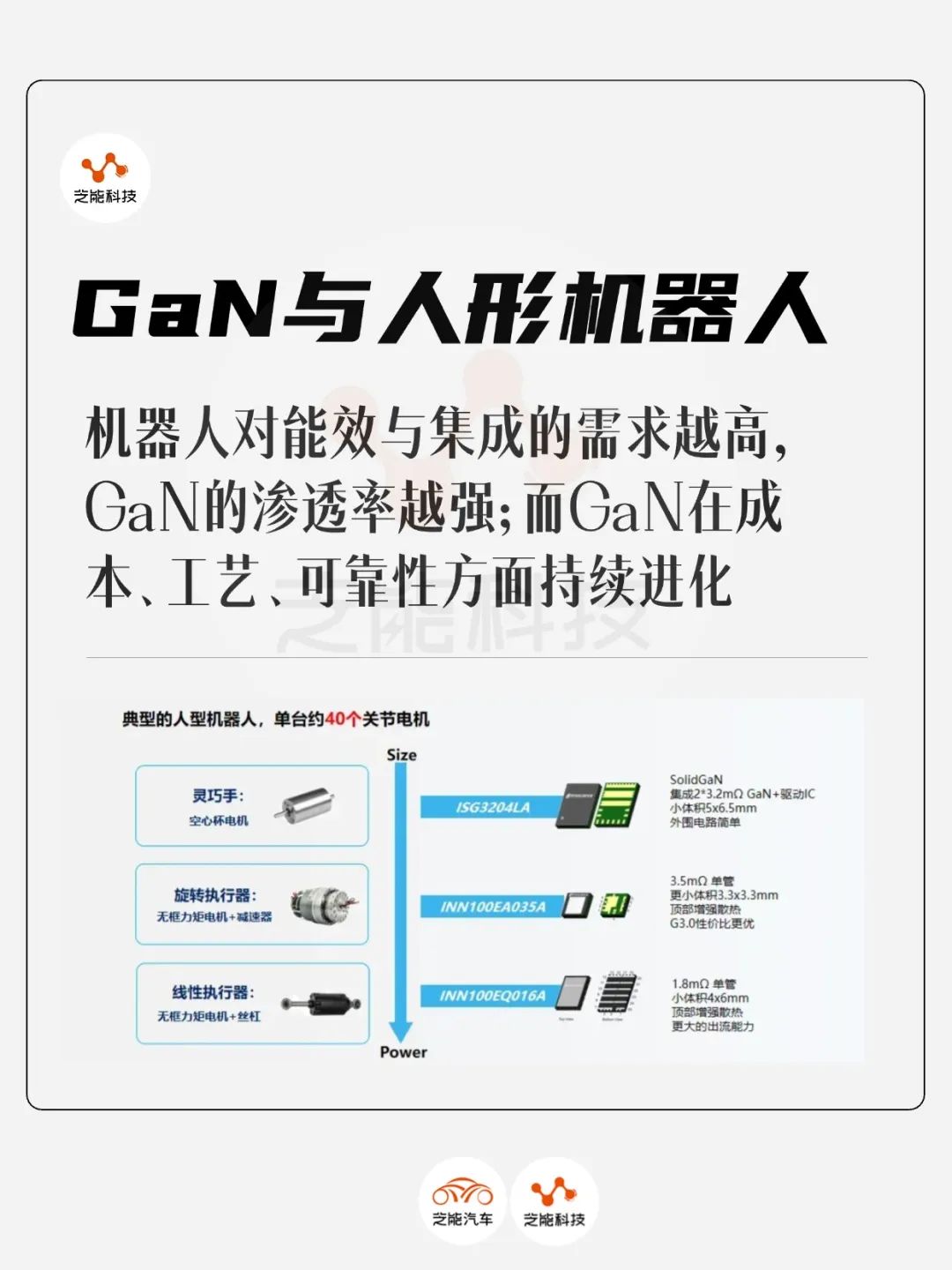

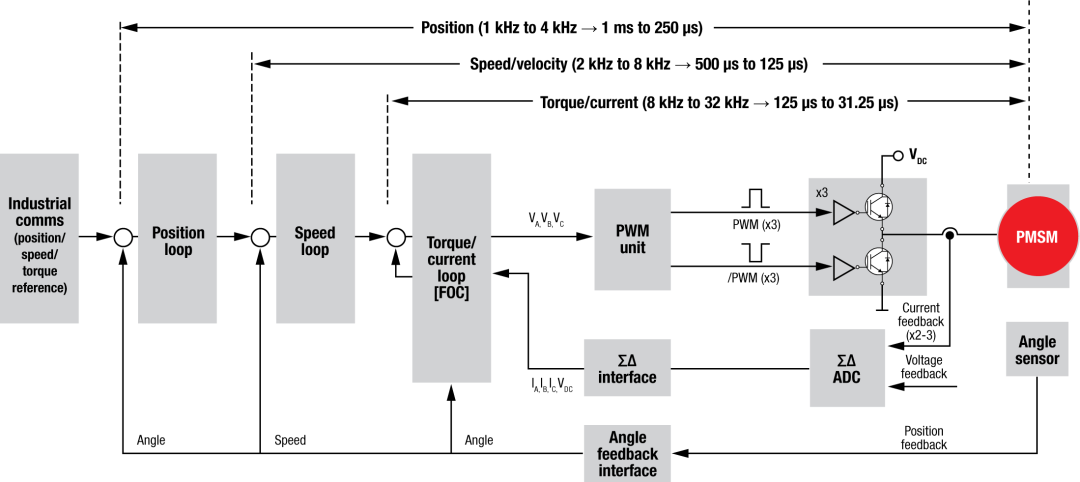

The lifelike movements of humanoid robots are facilitated by over 40 servo motor control systems distributed throughout their bodies, akin to human muscles and nerves. In precision parts like fingers, necks, and hips, the motor control circuit's response speed and accuracy dictate the robot's movement naturalness and stability.

Traditional silicon-based MOSFETs struggle with high switching losses at high frequencies, making it challenging to meet the demands of compact spaces, centralized power supply layouts, and high-frequency precision control. GaN devices, however, naturally boast higher switching speeds and smaller input/output capacitance values.

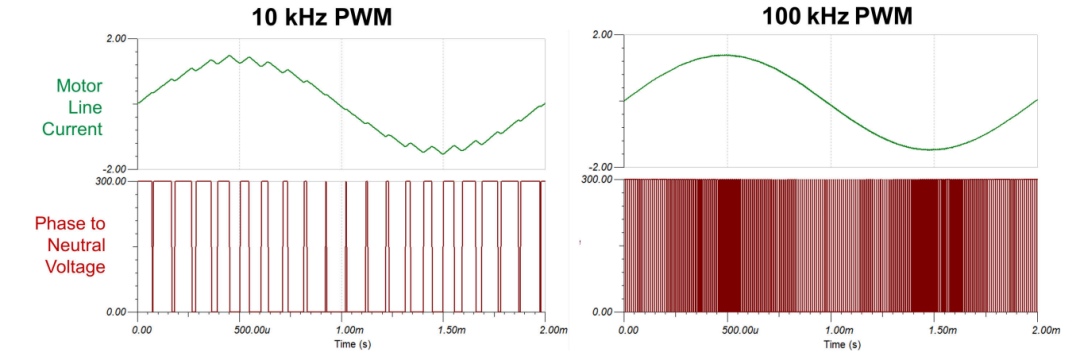

For instance, when grasping a glass with fingers, the motor must accelerate from rest to 500rpm within 0.1 seconds, requiring PWM frequencies of at least tens of kHz. MOSFETs often suffer from heat loss and EMI issues under such high-frequency operations, necessitating larger cooling structures. Conversely, GaN devices operate stably at 100kHz or higher, reducing system losses by over 85% compared to silicon without additional temperature rise.

Beyond frequency response, GaN excels in size reduction. In a joint cavity with a diameter under 10 centimeters, silicon-based devices struggle to fit motor drivers, sensors, reducers, and power capacitors. GaN, however, achieves over 50% area reduction through small-size packaging and integrated drivers. For example, Innoscience's products halve the size of joint drive circuit boards, solving space layout issues while maintaining efficiency.

In terms of control, GaN devices have a shorter dead time (10-20ns), significantly reducing motor current fluctuations compared to MOSFETs' approximate 1μs. Additionally, they lack reverse recovery current (Qrr), avoiding EMI interference from traditional body diodes, thereby enhancing multi-motor coordinated control stability.

In standard circuit design, as demonstrated by TI's TIDA-010936 platform testing, increasing the PWM frequency from 20kHz to 80kHz allows the GaN platform to replace traditional electrolytic capacitors with all-ceramic capacitors, reducing the DC bus section's volume while enhancing reliability—crucial for high-speed, high-vibration humanoid robots.

In three-phase drive applications, TI's LMG2100 series offers a representative solution: integrating high-voltage half-bridge GaN FETs with drivers in a 4.5×5.5mm package, supporting currents up to 55A, and incorporating functions like short-circuit and undervoltage protection.

Servo drivers built on such platforms simplify circuits, compact layouts, and enhance anti-interference performance due to reduced parasitic inductance, perfectly aligning with robots' stringent size and high-density design requirements.

GaN devices provide transformative technical support for humanoid robots across response speed, control accuracy, space integration, and energy consumption management. GaN FET technology's preference in humanoid robots stems from its comprehensive fulfillment of servo control system requirements for high-frequency switching, low loss, small packaging, and high power density. In complex multi-degree-of-freedom motor layouts, GaN bridges the gap between robot control accuracy and volume constraints.

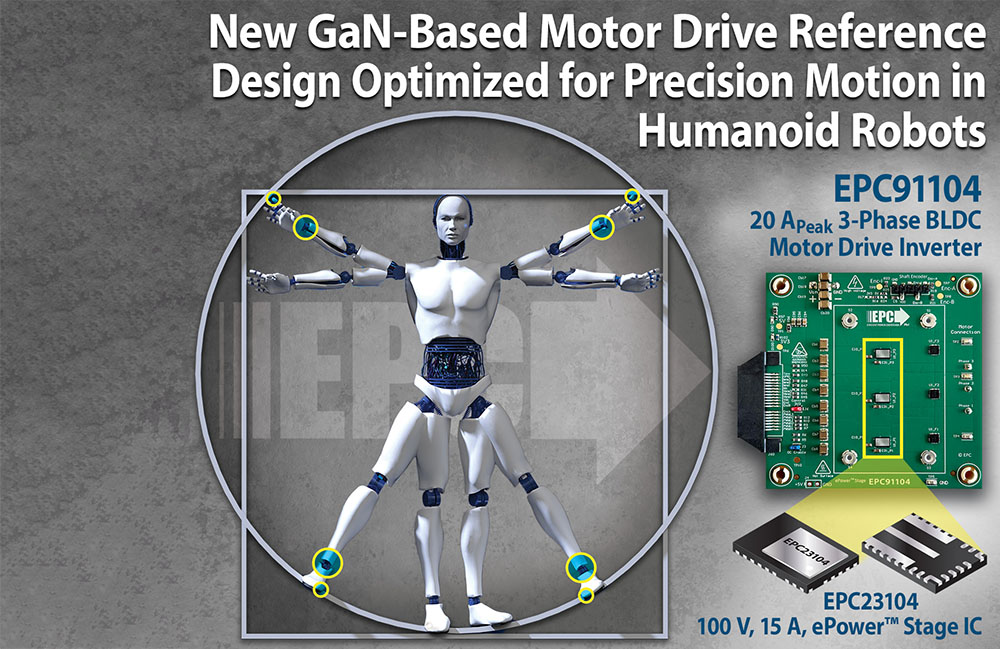

Part 2: Analyzing GaN Application Cases: EPC91118's Practical Integrated Design

Shanghai Zhiyuan's choice in the humanoid robot industry chain paves the way for GaN's industrial application. It selects Innoscience GaN chips for humanoid robots, initially deploying them in critical joints like necks and elbows, with three GaN devices per motor driving modular machine applications.

This marks GaN's transition from sample verification to large-scale delivery in the shift from consumer electronics to industrial-grade systems.

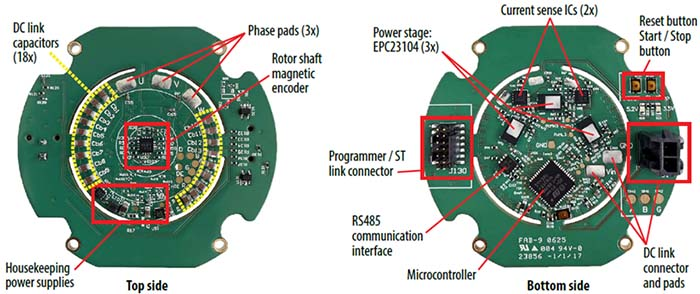

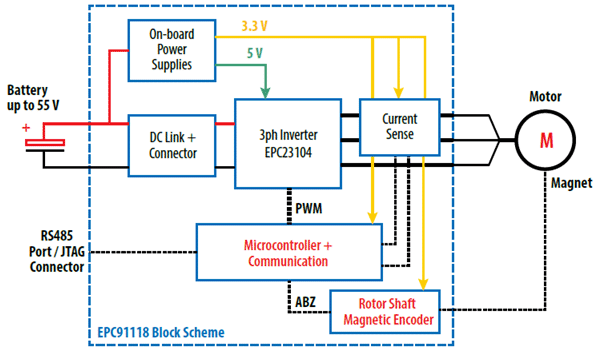

EPC's EPC91118 reference design, based on the EPC23104 monolithic integrated GaN device, is tailored for humanoid robot joints. With a diameter under 55mm, it supports up to 15A RMS current and operates in a 100kHz high-frequency PWM mode with a 50ns dead time.

The motor control board integrates a three-phase GaN inverter, magnetic encoder, current detection, microcontroller, RS485 communication, and various power modules. Its engineering value lies in three key aspects:

◎ High integration: Encapsulating the control system, drive circuit, power management, and feedback channel in a compact circular PCB simplifies system design complexity.

◎ Strong structural adaptability: Direct installation in the humanoid joint cavity without additional transmission or wiring optimizes joint volume utilization.

◎ Significant efficiency improvement: Measured under rotor speeds of 50 to 150rpm, system efficiency remains stable under varying load torques, crucial for high-speed response and low power consumption.

During development and testing, EPC91118 communicates via a standard RS485 bus and supports JTAG debugging, easing the engineering process. The design's use of MLCC instead of electrolytic capacitors not only reduces volume but also enhances system reliability, meeting robot lifetime and stability requirements.

From a holistic perspective, this GaN reference design transcends single device replacement, representing a novel motion control platform approach. GaN is no longer merely a performance enhancer but integral to robot electric drive system design logic.

Summary

Humanoid robots' commercial boundaries are sharpening, with control accuracy, energy efficiency, and space integration posing technical challenges. GaN technology offers a foundational solution with systemic breakthrough potential. Beyond being smaller, faster, and more power-efficient, in servo scenarios demanding high control accuracy and limited size, GaN and humanoid robots form a virtuous cycle: increased robot demands for energy efficiency and integration strengthen GaN's penetration, while GaN's evolution in cost, process, and reliability spurs robot design innovation.