The Intricacies and Evolution of Dexterous Hands in Robotics

![]() 08/05 2025

08/05 2025

![]() 506

506

Dexterous hands are currently in a developmental phase where technology, product strategies, and business models have yet to converge. As a pivotal component of humanoid robots, the advancement of dexterous hands might be more pressing than that of robots themselves. The challenges emerging during this period of rapid growth present opportunities for future breakthroughs.

Editor: Lv Xinyi

At the World Artificial Intelligence Conference (WAIC), when you pick up a magnifying glass, you'll notice an intriguing phenomenon:

On one side, there are highly sophisticated five-finger dexterous hands, capable of high degrees of freedom, tactile and force control, and millisecond-level command response times. They can perform delicate tasks like pinching tofu, solving Rubik's Cubes, and mimicking human hand movements. Conversely, the end effectors mounted on robots or robotic arms are often two-finger grippers, showcasing precise operations such as egg carving and playing mahjong.

The clash between two-finger and five-finger dexterous hands observed in on-site demonstrations is also evident in manufacturers' attempts to showcase their models' capabilities. For flexible long-range tasks, manufacturers prefer two-finger grippers. Even when using five-finger dexterous hands, most grasping, folding, and handing over actions are completed using only two fingers. A robot body manufacturer revealed to Embodied Learning that the reason is "stability in demonstrations, and two-finger grippers are indeed more stable."

This phenomenon is not unique to China. Foreign robot body manufacturers have also broadcast long-term work sessions, where throughout the broadcast, most fingers were not heavily involved in the work, relying primarily on two fingers to complete tasks.

Behind this phenomenon lies the question: Are dexterous hands inherently difficult to use, or do scenarios simply not require them? Is there a significant gap between testing and practical application?

Some believe that the core of robots' dexterous manipulation hinges on highly advanced hands, as tools in human society are designed for human hands, giving dexterous hands a natural scenario advantage. Others argue that five fingers are redundant and that in industrial scenarios, most tasks can be efficiently completed using grippers.

Secondly, do robot body manufacturers need third-party dexterous hands? While dexterous hand manufacturers possess their own expertise, compatibility issues with robot bodies arise. Is it a choice between self-development for cost control or pursuing high performance? This dilemma may further escalate into a clash between maximizing long-term profits and short-term business feasibility.

Thirdly, what kind of dexterous hand offers productization feasibility? Currently, the evaluation of dexterous hands is not about the prominence of a single performance indicator but about seeking a balance. While maintaining baseline performance, they must also offer a price advantage. Hexagonal products, balancing multiple dimensions, may prove more popular.

It's evident that dexterous hands are currently in a developmental phase where technology, product strategies, and business models have yet to converge. As a core component of humanoid robots, the advancement of dexterous hands might be more pressing than that of robots themselves. The challenges emerging during this period of rapid growth present opportunities for future breakthroughs.

Are dexterous hands truly dexterous?

Looking solely at dexterous hand products, the diverse options on the market have reached new heights of competition.

The intelligent DexHand021Pro can replicate the action of turning a bowl upside down to pour water due to its "wrist coordination." BrainCo's ultra-lightweight dexterous hand, Revo2, weighs only 383g but can lift objects weighing 20kg. AOYI Technology's ROH-AP001 can perceive subtle pressure changes from 0.1N to 25N in real-time, making it easy to pick up potato chips or hold heavy tools...

Image Source: InTime Robotics

Overall, the advantage of third-party dexterous hands lies in their vertical expertise. On one hand, most manufacturers have backgrounds in components like motors and connecting rods, giving them an edge in component reliability and large-scale mass production. On the other hand, due to their early entry and deep cultivation in this field, they have a significant lead in multiple core technical indicators.

For instance, InTime Robotics relies on its micro servo cylinder technology, self-developed hollow cup motors, planetary roller screws, and closed-loop control systems to highly integrate drive, transmission, and sensing, achieving structural simplification and a leap in reliability for dexterous hands. Currently, thousands of units have been shipped, and the product has iterated to the fifth generation.

On the other hand, Lingxin Qiaoshou breaks the upper limit of degrees of freedom. Its research-grade dexterous hand can have 42 degrees of freedom, far exceeding the British ShadowHand (24DoF) and Tesla Optimus Dexterous Hand (22DoF). Even in terms of degrees of freedom, it has surpassed human hands to some extent (27DoF).

Image Source: Lingxin Qiaoshou

However, it's noticeable that two-finger grippers are still more frequently used when truly demonstrating model capabilities or performing precise operations. At the WAIC conference, the robots from Galaxy General used two-finger grippers for tasks such as business supervision, spare parts sorting, and material box handling. Other manufacturers also employed two-finger grippers for scenarios like fetching and delivering beverages and making ice cream.

The primary issue with not using dexterous hands is that they don't seem as dexterous as anticipated. During research by Embodied Learning, many robot body manufacturers provided feedback. Some manufacturers stated, "Many dexterous hands break down within a few hours of testing." Others conducted horizontal comparisons, finding that "At this stage, two-finger grippers are still more cost-effective."

It appears that while dexterous hands might not have obvious issues in standalone demonstrations, they face challenges such as delayed response, force control errors, hand-eye coordination, and multi-modal data fusion when paired with robot bodies.

Therefore, some manufacturers choose to develop their own hands to achieve independence. Robot body manufacturers like Xingdong Jiyuan, Zhiyuan Robotics, Unitree Robotics, and others have successively launched self-developed five-finger dexterous hands.

Self-developed dexterous hands can be well adapted to their own motion control algorithms, solving issues of hand-eye coordination and communication delays. With a deep understanding of their robots' overall architecture, motion characteristics, and sensor layout, robot body manufacturers can deeply integrate the design of dexterous hands with the robots' motion control algorithms, making hand movements more coordinated with the robot's overall movements and enhancing operation fluency and accuracy.

Besides adaptation, cost control is another crucial reason for choosing self-development.

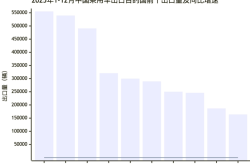

Dexterous hands account for about one-quarter to one-fifth of the overall cost of the robot, making them the largest cost component. In the process of reducing costs to enter the market, how to lower the cost of end effectors determines whether the overall cost can truly be minimized.

Moreover, self-developed dexterous hands can be seamlessly connected with other sensors of the robot to achieve real-time data sharing. For instance, when the visual sensor detects changes in an object's position and orientation, the motion control algorithm can quickly adjust the grasping action of the dexterous hand to ensure stable and accurate grasping. Currently, there's a trend in the industry for VLA models to evolve towards VTLA multi-modal operation models, where tactile data from dexterous hands is crucial for model iteration.

Furthermore, some manufacturers have introduced end effectors with commercialization potential by selling hands. For example, in Pasini's development path of "tactile sensors - dexterous hands - humanoid robots," dexterous hands play a vital role in accumulating technical assets and financial returns for humanoid robots.

The current situation faced by "hands" can be seen as a microcosm of "hardware restricting software." Many founders of robot body enterprises have told Embodied Learning that current hardware cannot fully restore model capabilities.

ALL IN ONE or On-Demand Adaptation?

Behind the lack of widespread application of dexterous hands lie not only their own developmental factors but also a game of perspectives among enterprises. Whether self-developed or third-party dexterous hands, there's still no consensus on "having to do five fingers." This lack of consensus stems from different product logics.

Advocates of two-finger grippers, like Matei, the creator of Grasplt software, argue that two-finger clamps can solve 95% of the problems in human society, and the remaining problems are difficult to solve even with dexterous hands. However, a more convincing reality is that two-finger grippers can effectively reduce the cost of end effectors and optimize the cost structure. At the same time, two fingers are highly reliable due to their single and stable motion form, making them convenient for control in repetitive tasks for specific clamped parts, which is also a point considered by the industry.

Image Source: DaiMeng Robotics

Three-finger grippers are similar to two-finger grippers but offer a more stable triangular structure that can better clamp irregular objects.

Currently, two-finger technology is relatively mature, and few companies sell it as a standalone product. However, three-finger products are commonly sold and applied, such as the DexHand S launched by Lingchu Intelligence in May this year, the Dex3-1 used in previous desktop operation videos by Unitree Robotics, and the gripper used by Boston Dynamics for cargo handling.

Image Source: Unitree Robotics

Manufacturers of four-finger and five-finger dexterous hands believe that the difference between dexterous hands and two-finger or three-finger grippers lies in the fact that grippers cannot handle many precise operations. From a product logic perspective, five-finger dexterous hands can be seen as the ultimate solution, creating a truly universal product that can meet most needs.

These companies argue for pursuing true high dexterity, suggesting that low-dexterity hands might as well be directly made into grippers. Zhu Huahua, CTO of Lingchu Intelligence, said, "Binding the ring finger and little finger will restrict 70% of daily operations." Some investors also believe that the entire human social environment, tools, and scenarios are optimized for human hand structures, making bionic dexterous hands the most suitable for human society.

It's worth noting that five-finger dexterous hands are currently the most controversial. Some believe they are the industry's obsession with "anthropomorphic product forms." Fu Sheng, CEO of Cheetah Mobile, once said that this stems from "humans' fascination with their own form." The Da Vinci surgical robot can perform delicate operations using only two fingers. Some companies even adopt five-finger dexterous hands not for scene operations but simply as a part of constituting a "humanoid," which is also one of the two markets mentioned by Zhou Chen, CEO of Lingchu Intelligence, "paired with humanoids and robot bodies, appearing as such."

Therefore, for robot body enterprises, is it "good enough" to choose grippers, or is a "five-finger dexterous hand indispensable for complex scenarios?"

In general, the choice behind these paths is a game of product logic, requiring a delicate balance between cost and performance in different scenarios to find Product-Market Fit (PMF) as much as possible.

However, there's a "phased solution choice." Different stages have different PMF pain points. For example, in industrial scenarios, PMF might be "100,000 fault-free operations," so the simple structure of two-finger grippers is less prone to component damage. In household scenarios, PMF might be "precise manipulation of flexible objects," so five-finger dexterous hands may have a higher completion rate for grasping irregular objects.

This also reveals a trend: the demand for precise robotic operations is becoming clearer. As scenarios transition from structured to unstructured, and standard factory operations shift to commercial services and then into non-standard households, the dexterity requirements for robotic end effectors will increasingly rise.

Finally, the technology of dexterous hands itself has not yet converged, such as whether to use tendon drive or rigid direct drive. The divergence in technical routes leads to fragmentation of the supply chain, making it difficult for suppliers to achieve large-scale production and keeping costs high. These costs are also a significant factor influencing robot body manufacturers' choice of dexterous hands.

Not Absolute Indicators, But Relative Balance

Based on the contradiction between industry technology evolution and industrial implementation, the essence of competition for dexterous hands has shifted from a "parameter race" to a "multi-dimensional system balance."

An illustrative example is that, during a certain period, manufacturers of robot bodies or dexterous hands introduced their products, each claiming to offer more than ten or twenty degrees of freedom. Even the term "passive degrees of freedom" emerged during this time. However, nowadays, "degrees of freedom" are gradually being phased out as a mere marketing gimmick, and "not competing on degrees of freedom" has become an industry consensus.

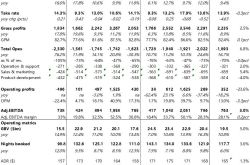

In essence, avoiding competition on parameters, especially degrees of freedom, boils down to cost control.

The market is not devoid of functional dexterous hands. For instance, Tesla's 22-degree-of-freedom dexterous hand still accounts for 17% of the robot body's cost post-reduction, equivalent to approximately one basic version of the Unitree G1. The British Shadow Hand, with 24 degrees of freedom, retails for around $80,000, equivalent to 5.5 G1s. Clearly, this does not align with productization logic. Hence, price remains a critical indicator. Many manufacturers are well aware that the dexterous hands they currently procure are not highly integrated with their robot body algorithms, yet they prevail due to cost-effectiveness.

Therefore, dexterous hands prioritize two aspects: performance, ensuring the technology meets operational requirements; and production capacity and cost-effectiveness, emphasizing engineering implementation.

Currently, the industry is striving to overcome the "impossible triangle" of "cost-system parameters-stability" and aims for "hexagonal warriors" that strike a multi-dimensional balance among factors like strength, speed, volume, weight, lifespan, degrees of freedom, and structural strength. This hurdle must be overcome for dexterous hand robots to reach consumers.

Among these factors, pursuing sufficient strength and load in industrial scenarios often necessitates high-torque motors and rigid materials, which inevitably increases weight. Similarly, pursuing more degrees of freedom can hike costs, increase the risk of part damage, and compromise lifespan and stability.

Moreover, the industry is expanding its evaluation dimensions beyond these indicators. For example, Zhou Chen, CEO of Lingchu Intelligence, believes that the dexterity of dexterous hands should meet the Index of Dexterity (IOD), Index of Sensation (IOS), and Index of Intelligence (IOI).

The IOD encompasses joint degree-of-freedom configuration and workspace size; the IOS focuses on measuring dynamic characteristic information of hand-object interaction, such as friction, alongside basic parameters like sensor type, range, coverage area, accuracy, and dot matrix density; the IOI reflects the evolution level of cognition and decision-making, demonstrating the hand's ability to autonomously complete diverse tasks in complex, dynamic environments, and even continuously optimize operation strategies through experience accumulation.

In summary, what kind of dexterous hands will be in demand in the future, and what is the technology's development path? There is no definitive answer yet. However, it is evident that robot manufacturers value a multi-dimensional balance when selecting dexterous hands. This aligns with the current demand for robots that can be rapidly implemented and applied, reducing costs, operating stably, achieving large-scale deployment, and ensuring product completion without compromising one aspect for another, making them the most competitive.

The industry has never been short of single-point technological breakthroughs, but whether these technologies can transition from the lab to the market depends on whether each company's product can correct the "rose diagram" of product strength.

The presence of dexterous hands at WAIC reflects the industry's exploration towards maturity, and the logic of "defining technology by scenario" is already evident. The current seemingly "crude" two-finger grippers and the future potentially popular "hexagonal" five-finger hands will eventually yield the most suitable answer for the industry's rules through market selection.