Peering into Midea: Witnessing the Profound Awakening of the Robotics Industry

![]() 08/06 2025

08/06 2025

![]() 687

687

Article / Liu Jin

Source / Jie Dian Cai Jing

In 1927, Westinghouse Electric Corporation introduced the world's first humanoid robot, "Televox." It wasn't until nearly a century later that the robotics industry resurfaced at the forefront of technology, driven by tech giants like Boston Dynamics and Unitree. Today, the robotics sector boasts numerous players, with companies from various industries—home appliances, automobiles, and transmissions—entering the fray.

Large home appliance enterprises, for instance, possess a diverse product range and an inherent demand for smart home appliances, prompting many giants to extend their smart strategies into robotics. Recently, Haier Group's Chairman and CEO, Zhou Yunjie, predicted that maid robots capable of addressing housework, care, and emotional needs will become more prevalent household infrastructure than automobiles. Meanwhile, Midea, the first local home appliance company to venture into robotics, unveiled its household humanoid robot "Mira" at the recent World Artificial Intelligence Conference.

01 Midea: A "Hidden Robotics Giant"?

A few years back, Midea's acquisition of Kuka Robotics was seen as a "bold crossover" by the industry, with some expressing skepticism. However, it has now emerged as a classic case of Chinese home appliance enterprises' foray into robotics. Kuka, known as one of the "Big Four" in industrial robots, is a 126-year-old German star enterprise.

Why did Midea choose to directly acquire Kuka?

Firstly, it was a forward-thinking move. As early as 2015, Midea jointly established two robotics companies with Yaskawa Electric, another member of the "Big Four." In 2016, Midea invested 178 million yuan in a robotics manufacturing enterprise named Efort. Before acquiring Kuka, Midea had already been actively deploying industrial robots, perhaps with the intention of "reducing costs and increasing efficiency."

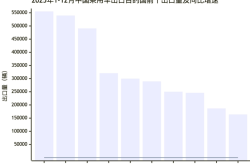

Secondly, Midea needed robots for its own operations. Since 2012, Midea has been using robots on a large scale to enhance its smart manufacturing capabilities. After joining Midea, Kuka capitalized on the opportunity to tap into China, the world's largest industrial robot market. Today, Kuka robots are widely used in automobile production lines and are common sights in factories of Tesla, BYD, and CATL. Kuka's industrial robot business has expanded beyond simple production work, venturing into diversified and customized high-end manufacturing fields such as new energy, automobiles, aerospace, and other national strategic industries.

Kuka's Product Line

As of 2024, Kuka's market share in China has remained stable at TOP4. In early May this year, Midea's self-developed industrial humanoid robot "Milo" was officially deployed in industrial scenarios, marking the entry of domestic service robots into the core field of smart manufacturing.

Unknown to many, Midea's Kuka Smart Manufacturing Science and Technology Park in Shunde, Foshan, has become China's largest industrial robot production base, with a cumulative production and delivery of over 80,000 industrial robots. Now, relying on brands such as Kuka, Swisslog, Gorbel, and Jiaya Precision Machinery, Midea has achieved full coverage from core components to overall solutions, from hardware equipment to intelligent systems, becoming one of the top four industrial robot manufacturers globally and a "hidden giant" in robotics.

Entering 2025, the core reason behind the industry's enthusiasm for robots is that large models have pushed the evolution upper limit of all intelligent terminals.

Therefore, leveraging industrial robots like Kuka, Midea's "humanoid robot" made a swift debut, embodying both industrial features and rapid intelligent application. In household and industrial scenarios, household scenarios are more complex, primarily testing a robot's reasoning, decision-making, and flexible manipulation abilities. Industrial robots provide Midea with the technological foundation in core components for entering the humanoid robot market.

Jie Dian Cai Jing learned that Midea's Humanoid Robot Innovation Center was established in 2024, and this year, it has deployed three robot platforms: humanoid-like, fully humanoid, and superhumanoid. It is currently advancing technological research and development in core joints, sensors, and components such as hands and bionic arms/legs.

A robotics hardware engineer told Jie Dian Cai Jing that, from a competitive perspective, home appliance giants like Midea can utilize profits from home appliances to provide more support for robots. Although humanoid robots are latecomers, they are "fast enough." Public information indicates that in the next three years, Midea plans to invest at least 50 billion yuan in research and development, focusing on cutting-edge technological fields such as AI large models, new energy, robotics, and embodied intelligence. For other robotics enterprises, raising over 1 billion yuan in funding is already the "ceiling."

Midea's Humanoid Robot Mira

This year, humanoid robots have already been applied in closed/semi-closed scenarios such as supermarket restocking and unmanned pharmacies. There are also robot prototypes developed by manufacturers like Midea and Haier that can perform household chores and assist the elderly, but mass production and popularization still require time. However, this large-scale "technological arms race" investment is something that giants can afford and bet on.

02 The Breaking Wall Advantage of Giants in the "Cyber World"

Regarding home appliance giants entering the robotics field, there's often a misconception: will all home appliance enterprises produce robots in the future?

In reality, humanoid robots and home appliances are not mutually exclusive; rather, the organic integration of humanoid robots and smart home appliances facilitates their entry into household scenarios, enabling all-round "active service," such as having the robot automatically put dirty clothes into the washing machine and hang up the cleaned ones.

Therefore, the top priority for realizing the robot's "cyber dream" is that technology must serve real needs.

For example, in smart homes, Midea is exploring the application of humanoid robots in four typical scenarios: storage, cleaning, laundry, and cooking. It is necessary to invest heavily in developing high-precision humanoid robots and for giants to first integrate robot technology into existing home appliance products to address specific pain points in users' daily lives. Most home appliances have the potential to be combined with humanoid robots, including washing machines, refrigerators, dishwashers, etc. This "small steps, fast run" strategy is more pragmatic for enterprises and easier to gain market recognition.

Secondly, to bridge the technological gap in the "cyber dream," a single technology alone cannot build an intelligent ecosystem.

Taking research and development as an example, Midea Group has multiple research institutions related to robots. In addition to the National Key Laboratory for High-end Heavy-duty Robots (Midea Blue-Orange Lab), Midea Group's Central Research Institute, AI Research Institute, Smart Manufacturing Research Institute, etc., are closely linked to the robotics industry.

Jie Dian Cai Jing learned that Midea does not set KPI assessments for its robotics research and development team, allowing 30% of "free exploration" time, which has given birth to core technologies such as bipedal balance control algorithms, laying the foundation for humanoid robot research and development.

Over the past five years, Midea Group has invested over 60 billion yuan in research and development, accelerating cutting-edge technological innovation in AI, robotics, and other fields.

For instance, the Blue-Orange Lab is the only national key laboratory in the robotics field relying on an enterprise platform. Its mission is to conduct cutting-edge technological research on high-end heavy-duty robots, guided by the high-end demands of the strategic equipment industry. Currently, it has established a systematic scientific research innovation and industrialization pattern with one headquarters, three international sub-centers, and two industrialization bases. Blue-Orange boasts over 200 scientific researchers, 8 industry-leading experts, 8 nationally recruited experts, and a 42% proportion of PhDs.

Since 2023, the Blue-Orange Lab has won 13 scientific and technological awards, including the China Machinery Industry Science and Technology Award and the China Automation Society Science and Technology Award. Nine of the lab's scientific and technological achievements have been assessed as internationally leading by an expert panel of academicians. The lab has led or participated in the formulation of 13 international/national standards in the robotics field, and lab experts serve as members of ISO/TC299 and ISO/TC110 international standard committees.

Only with extensive and profound research and development results can solid support be provided for humanoid robots to enter everyday life.

Midea Blue-Orange Lab

Finally, the industrial chain is the foundation for realizing the "cyber dream." Supply chain maturity and cost control are another major challenge.

If humanoid robots are to become consumer-grade products, they not only require mature technology and products but also a robust supply chain to support a trillion-level market. Enterprises must consider the level of cost reduction necessary for consumer acceptance, placing extremely high demands on the supply chain's capabilities for large-scale production and cost optimization.

Jie Dian Cai Jing learned that leading enterprises such as Midea have plans to reduce robot costs. Midea said that from a design perspective, it is actively exploring design innovations and optimizations, reducing the number and weight of components through more integrated design, while achieving the dual purpose of cost reduction and performance improvement.

Moreover, over the past two decades, giants like Midea have acquired and integrated a plethora of brand and industrial chain companies under the group. These enterprises have either become independent sub-brands or transformed into core fulcrums in the supply chain. The scaled synergistic effects formed by this (such as joint purchasing bargaining power, technology module reuse, and flexible manufacturing networks) are continuously being converted into cost advantages for the robotics business.

Therefore, although humanoid robots are accelerating from "showcasing skills" to "practical use," they still need to cross multiple thresholds, including technology, supply chain, and cost. Midea and others may be the first enterprises to surmount these hurdles.

03 The "Hundred Schools of Thought" in Robotics: A Game of "Competition and Cooperation"

In the manufacturing industry, not only predecessors like Midea but also younger generations are competing with them in the layout of the robotics industry for the "pearl" in the field of industrial manufacturing.

For instance, while Midea has Welling motor, Ecovacs has Kaihang motor; while Midea has Kuka robots, Dreame has incubated Magic Atom humanoid robots. Although the younger generation does not have as deep an accumulation as Midea, the wave of embodied intelligence will accelerate the maturity of emerging enterprises and products.

Therefore, what determines victory or defeat is no longer sales figures but the ability to evolve closer to the future.

The first is the evolution of identity: Enterprises are transitioning from single product manufacturers to technology and solution integrators to smart ecosystem builders.

For example, Midea has successively ventured into robotics, smart building technology, new energy photovoltaics, and energy storage industries. Midea also aims to spin off its robotics and automation systems business for listing. Haier acquired GE Appliances and Fisher & Paykel, integrating global R&D and supply chain resources to enhance solution capabilities, etc. Ecovacs, Dreame, Roborock Technology, and others are also undergoing similar transformations.

Jie Dian Cai Jing also found an interesting example. Since this year, a significant number of catering bosses have started rushing to buy cooking robots. Xiaocaiyuan recently plans to purchase 2,000 cooking robots at a unit price of 50,000 yuan; the prospectus of Laoxiangji disclosed that as of April, 388 of its stores had adopted automatic equipment; JD.com's "7FRESH Kitchen" has also made large-scale investments in "robot cooking"; and Tineco Smart Kitchen, a subsidiary of Ecovacs, has already started cooking in supermarkets in Jiangsu. Many cooking robot brands have also ventured overseas to Europe and America, replacing more expensive local labor. This demonstrates that the construction of a smart ecosystem actually lies in every simple market demand.

The second is market evolution: The path of Chinese manufacturing going global has evolved from outputting cost-effectiveness to later outputting reliability, exemplified by the overseas expansion of smart products from Midea, Haier, Ecovacs, Roborock, etc. The commanding heights of future competition will be the output of ecosystems and smart manufacturing methodologies.

Recently, domestic lawnmower robots have surged with robust momentum, emerging as a favored star in overseas markets. Domestic robotics and garden equipment manufacturers like Ninebot, Ecovacs, Greenworks, and Daye have achieved remarkable success, with the international expansion of smart lawnmowers becoming a significant growth driver. Furthermore, advancements in technologies such as LiDAR and borderless navigation have significantly enhanced product performance and user experience. The accelerated localization of components like LiDAR has also reduced overall product costs, leading to more affordable prices. The phrase "I will manufacture whatever you need" embodies the confidence of the manufacturing industry in exporting smart manufacturing methodologies globally.

Additionally, there is a notable evolution in capabilities: The manufacturing industry's development model is transitioning from early-stage pursuit, acquisition, and imitation towards independent creation and ultimately leading innovation.

For companies like "Midea" that have ventured into robotics from manufacturing, as well as native robotics enterprises rooted in AI like Unitree and Zhiyuan, their path to independent creation follows a "three-step" approach, progressing from smart manufacturing applications and commercial services to household services.

For instance, Zhiyuan adheres to the principle of "from simple to complex" in advancing the commercialization of humanoid robots. Currently, Zhiyuan is already performing logistics sorting and has targeted three overseas markets: the Middle East, Southeast Asia, and Japan and South Korea. In the future, the application of humanoid robots in areas such as reception and guidance, entertainment and interaction, and handling and sorting, though seemingly "basic," is a crucial step for technology to take root.

These cross-border giants and pure AI companies are not competitors but collaborators. As manufacturing enterprises, they possess abundant application scenarios and can gather vast amounts of real data from factories, providing "raw materials" for robot skill learning. Simultaneously, they actively partner with external entities like universities to accelerate the research and development of the "robot brain." Leveraging the traction of application scenarios, enterprises like Midea are collaborating with the industry to expedite the genuine integration of humanoid robots.

The market will be the fairest inspector in the future.

Written at the end

As manufacturing enterprises like Midea shed the single label of "home appliance manufacturer," and as China moves beyond being solely known as a manufacturing powerhouse, while consumers worldwide focus on China's intelligent manufacturing, the pendulum of the times has swung in favor of the "Mideas." For these companies, the logic of innovation has shifted. From passive imitation to leading innovation, they now shoulder not only cutting-edge technologies like humanoid robots but also the historical responsibility and immense opportunities of deeply integrating robotics, automation technology, and the real economy, empowering the intelligent upgrading of numerous industries.

*The title image is generated by AI