In-depth Analysis of Unitree Robot Incident: Six-Axis Force Sensors as the Crucial Barrier for Human-Robot Safety

![]() 08/19 2025

08/19 2025

![]() 676

676

A Technical and Ethical Perspective on a Collision Incident

On August 15, 2025, the National Speed Skating Oval in Beijing hosted the inaugural World Humanoid Robot Games, witnessing both a historic moment and a distressing incident that raised ethical questions about technology. In the final stretch of the 1500-meter finals, Unitree Technology's H1 robot deviated from the track at a speed of 3.8 meters per second and collided head-on with a staff member, exerting an impact force of 120 kilograms, far exceeding the human sternum's tolerance limit (about 80 kilograms). The robot continued running until it secured the championship. This 15-second video swiftly went viral on platforms such as Reddit and YouTube, amassing over 200 million views. Overseas netizens sharply commented: "This isn't a 'Terminator' trailer; it's a live broadcast of ethical missteps in China's robot industry."

A Multifaceted Analysis of Technical Failures

The technical details of the incident revealed alarming safety vulnerabilities:

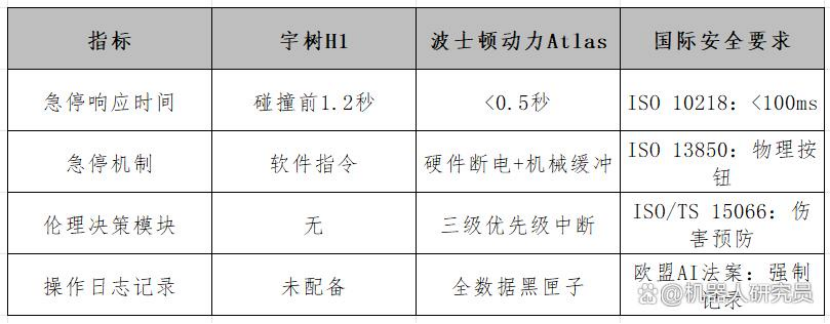

Perception-Decision Chain Breakdown: The 3D LiDAR on H1 detected the staff member at 0.5 meters but prioritized the race program, only triggering the emergency stop command 2 seconds before the collision. Fatal Remote Control Handover Mistake: During the handover of remote control between two operators, the acceleration button was accidentally pressed, highlighting the risks of manual intervention. In contrast, the runner-up "Tiangong Ultra" operated fully autonomously (average speed of 2.1 meters per second), while Unitree prioritized speed (3.8 meters per second) over autonomous technology validation. Lack of Safety Redundancy: As a high-end product priced at 650,000 yuan, H1 lacked a physical emergency stop button and an "injury prioritization avoidance" algorithm. This contrasts sharply with Boston Dynamics' Atlas, which powers down upon perceiving danger.

Ethical Dilemmas in Industry Response

The incident reflected the collective anxiety within China's robot industry:

Casual Post-Incident Handling: Founder Wang Xingxing dismissed the accident as an operational oversight, and the event organizing committee awarded the prize without rescinding the results. Professor Zhang Weili of Tsinghua University criticized: "When a 1.8-meter-tall metal machine moves through crowds at 18 kilometers per hour, no excuse of 'technological exploration' justifies the lack of safety redundancy." History of Safety Lapses: This wasn't an isolated incident; in June 2025, a Unitree robot stepped on a child's shoes during a public event, and in July, a dancing robot in a Hangzhou mall knocked over an elderly person due to light interference. Videos also circulated online showing test robots "chasing and attacking engineers." These incidents collectively pointed to systemic shortcomings in dynamic obstacle avoidance and ethical logic.

Regulatory Vacuum Indulgence: Although the event's "Competition Manual" allowed both remote control and autonomous methods, it didn't establish separate categories or mandate "operation log black boxes." This regulatory gap allowed Unitree to win honors through "semi-manual" methods that didn't reflect its technological capabilities.

Table: Performance Comparison Between Unitree H1 and Industry Safety Standards

Six-Axis Force Sensors: The Core of Safety Control

While public opinion focused on the robot's "cold escape," industry experts saw a deeper issue: the lack of force perception capabilities. As the "nerve endings" of robots, six-axis force sensors capture forces (Fx, Fy, Fz) and torques (Mx, My, Mz) in real-time, forming the perceptual basis for environmental interaction. If H1 had deployed high-precision six-axis force sensors at its wrists and ankles, the closed-loop force feedback between its soles and the ground could have prevented the disaster.

Technical Mechanism and Performance Barriers

Precision Measurement Principle: Strain-gauge six-axis force sensors (over 80% of mainstream solutions) use elastic body deformation to cause resistance changes in strain gauges, converted into voltage signals via Wheatstone bridges. The key lies in the decoupling algorithm, interpreting data from hundreds of sensitive points into six-axis force information. BluePointTouch's solution uses neural network optimization to achieve 1%FS accuracy, surpassing the industry average of 0.5%FS.

Challenges in Extreme Conditions: Under high-speed motion, sensors must maintain stability at a 10kHz sampling rate (responding to one data point every 1ms). This was the Unitree incident's pain point; its obstacle avoidance response delay was 200ms, equivalent to a dangerous distance of 1.3 meters for a human running blindfolded.

Overload Protection Design: High-quality elastic bodies balance stiffness and sensitivity. BluePointTouch's humanoid robot-specific six-axis force sensor series adopts a cross-beam structure, optimizing deformation characteristics through finite element analysis, enabling a 500%FS overload capacity to avoid permanent damage from collisions.

Rigid Demand Scenarios for Humanoid Robots

Dynamic Balance Control: When bipedal robots run, six-axis force sensors at their ankles monitor Z-axis pressure distribution and Mx, My flipping torques in real-time. If Unitree H1 had such sensors, it could adjust its gait instantly upon deviating from the track through a center-of-gravity compensation algorithm.

Collision Prediction Mechanism: When mechanical limbs contact humans, wrist sensors can trigger braking within 5ms through abrupt Fz pressure increases and abnormal Mx torque fluctuations. Unitree H1's "escape" behavior stemmed from the lack of such a force feedback loop.

Foundation for Compliant Operation: Future scenarios like grasping eggs and assisting the elderly rely on six-axis force sensors' millinewton-level resolution. BluePointTouch's LC series joint torque sensors achieve 0.1% accuracy per joint, providing delicate force control for 28-joint humanoid robots.

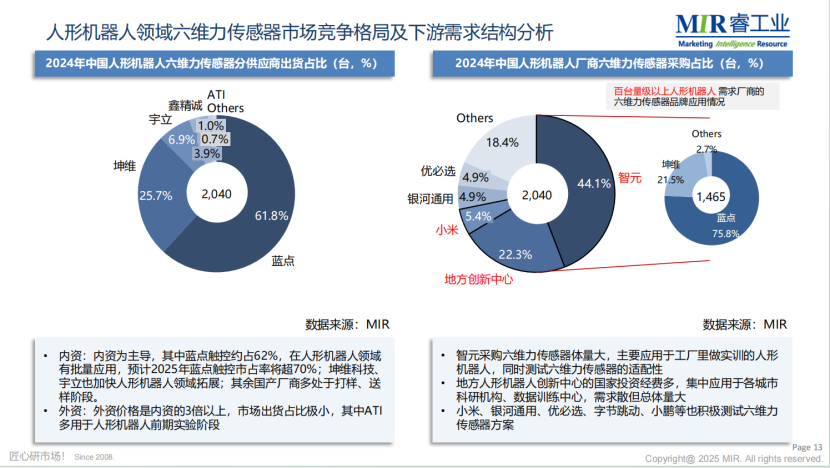

Domestic Breakthrough: BluePointTouch's Technological Leadership

Amid questions about domestic robot supply chains sparked by the Unitree incident, a 2019-founded company is reshaping the high-end sensor market landscape. Leveraging aerospace-level technology (with a core team from the University of Science and Technology of China and the China Aerospace Science and Technology Corporation), BluePointTouch captured 70% of the market share for humanoid robot six-axis force sensors in 2024 and shipped 70,000 sets of joint torque sensors in the first half of 2025 (95% of the domestic total). The nearly 100 million yuan B-round financing completed in July 2025 (led by GF Securities and Fosun Capital) accelerated its global expansion.

Constructing a Safe Future for Human-Robot Symbiosis

The Unitree incident serves as a prism, reflecting governance deficits in China's rapidly advancing robot industry. A Goldman Sachs report noted that the number of Chinese humanoid robot enterprises surged by 300% between 2023 and 2025, but 68% of their products hadn't passed basic safety certifications. To prevent technological advancements from evolving into ethical disasters, a trinity safety framework of "technology-systems-cognition" is necessary.

Immediate Technical Norms

Mandatory Hardware Redundancy: Following the EU's "Artificial Intelligence Act," humanoid robot competitions should be classified as "high-risk AI systems," mandating physical emergency stop buttons and collision buffering devices.

Ethical Algorithm Implantation: Incorporate unalterable injury prioritization principles at the decision-making level. MIT laboratories have verified that when the collision risk exceeds 0.3, robots should actively sacrifice task efficiency.

Data Black Boxes: Require storage of complete sensor logs for the 15 seconds preceding an accident. Had such a device been present in the Unitree incident, the remote control command sequence could have been traced.

Inevitable Path of Industrial Collaboration

Testing Scenario Innovation: Although Unitree H1 underwent 2,000 hours of closed testing, it didn't cover "human interaction during high-speed motion" scenarios. Dynamic interference test fields should simulate extreme situations like children suddenly entering the area.

Cross-domain Technology Fusion: Force perception needs to be fused with multiple modalities like vision and hearing.

Insurance and Financial Leverage: Promote "robot third-party liability insurance," increasing coverage from less than one million to autonomous driving levels. Use financial instruments to mitigate technological risks.

Rebuilding Public Trust

As social media trending topics like #RobotRampage emerged, rational enlightenment is crucial:

Technology Transparency: Open real-time data APIs for sensors, allowing users to monitor mechanical interaction states. This transparency is key to dispelling "black box fears."

Ethical Consensus Building: Conduct global surveys on "robot values," such as "whether robots should sacrifice themselves to protect children," with a 23% support rate difference between China and the West. Establish a baseline consensus through cross-cultural dialogue.

Educational Paradigm Transformation: Robot courses in universities should include "Introduction to Robot Ethics" to cultivate engineers' reverence for life's value. As Wang Xingxing reflected, "True intelligence isn't about running fast; it's about understanding the weight of life."

Rising from the Fall: A Civilized Measure

Unitree H1's "collision to win" exposed China's robot industry's shortcomings in core sensors but unexpectedly ignited the engine of industry transformation. As BluePointTouch's six-axis force sensors become the "nerve endings" of intelligent robots, and Tesla's Optimus learns "non-violent communication" protocols, we see a new path for human-robot symbiosis.

In 1885, Karl Benz's car was mocked as "inferior to horse-drawn carriages," but a century later, it reshaped human civilization. Today's robots that fell at the National Speed Skating Oval stand at a historical turning point. Treating every touch on the ground with aerospace-level rigor and setting global robot safety standards with Chinese wisdom is the profound lesson left by the Unitree incident for the industry.