15 Seconds per Flower: AI Revolutionizes Breeding Greenhouses - What Has "Jieer" Changed?

![]() 08/20 2025

08/20 2025

![]() 634

634

"Jieer" Intelligent Breeding Robot (provided by the research team)

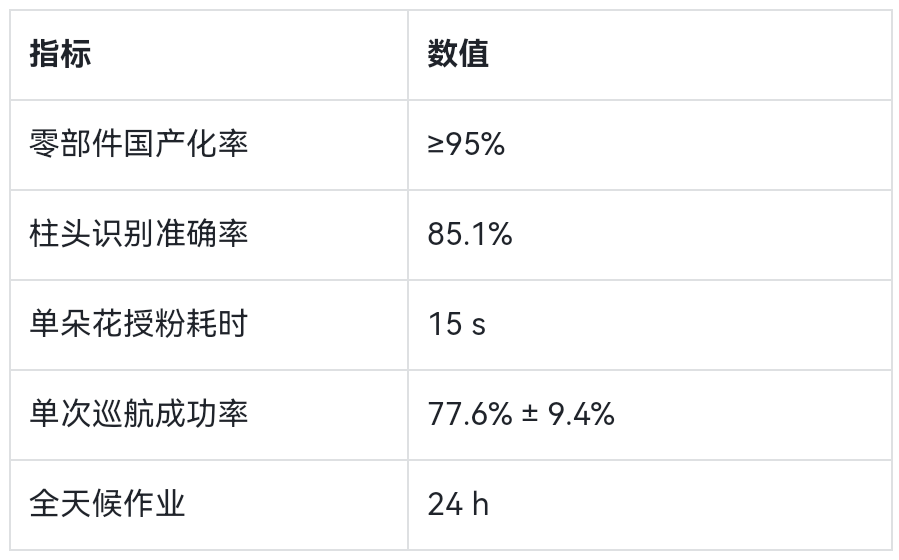

"15 seconds per flower, 77.6% success rate in cruise pollination, 95% localization rate of components..."

This is not merely a showcase of robotic prowess; it marks a technological shift impacting food security and farmers' livelihoods, propelling traditional empirical breeding into the era of precision agriculture.

By Wang Xian | Produced by Jixin

01 What Challenges Does Jieer Address?

To appreciate the significance of "Jieer," one must first understand the limitations of traditional breeding.

High Costs: The Burden of Manual Pollination

In traditional hybrid breeding, manual pollination is a bottleneck restricting efficiency. For instance, tomato hybrid seed production relies 100% on manual labor, with labor costs accounting for over 25% of total breeding costs. Of these, the "emasculation" process alone consumes 40% of expenses. This is a substantial burden, especially considering breeding cycles that often span several years.

Low Efficiency: The Time Window Constraint

The optimal window for pollination is narrow, typically requiring completion on the day of flowering; otherwise, fruit set rates significantly decrease. Manual labor struggles with slow response times and insufficient coverage. A skilled worker can pollinate thousands of flowers daily, but large greenhouses demand millions. This leads to missed pollination windows, reduced yields, and success rates.

Inconsistency: The Hidden Cost of Empirical Methods

Manual pollination relies heavily on experience, leading to significant variation in techniques. Some workers apply pollen moderately, while others are too rough, damaging flowers. This lack of standardization directly impacts hybrid breeding consistency and stability, potentially causing "batch differences" during new variety promotion, reducing market recognition.

Labor Shortage: The Dual Pressure of Aging and Migration

Traditional pollination's reliance on manpower makes it vulnerable to demographic changes. As the rural workforce ages and young labor shifts to cities, breeding bases face labor shortages. During flowering seasons, hiring difficulties and high labor costs are common. Some enterprises even recruit temporary workers across provinces, disrupting production plans and increasing costs.

Environmental Constraints: Bees Are Not Always Reliable

Some breeding processes rely on bees, but bee pollination is ineffective in modern greenhouses due to enclosed environments, insufficient lighting, and temperature fluctuations. Climate change also affects bee populations, weakening natural pollination sustainability. Manual supplementation increases labor intensity and costs.

Innovation Urgency: The Global Race for Variety Upgrades

Under pressure from climate change, food security, and global market competition, the breeding industry aims to shorten cycles, increase yields, and improve stress resistance. Traditional methods take 8-10 years to cultivate a new variety, while market demands have shortened this to 3-5 years. Manual pollination's inefficiency and high cost make this goal nearly impossible.

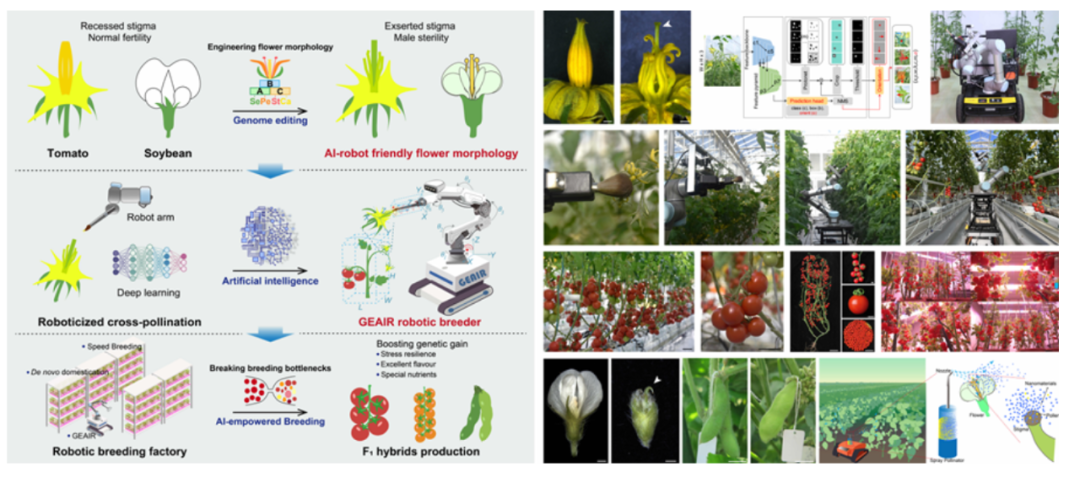

Traditional hybrid breeding faces a multi-faceted dilemma of "high costs - low efficiency - labor shortage - insufficient standardization - environmental constraints." Against this backdrop, "Jieer's" emergence is crucial. It's not just a robot but a new model combining "biotechnology + artificial intelligence," automating and enabling all-weather pollination through gene editing, AI visual recognition, and precise robotic pollen brushing. This marks the beginning of a new stage of standardization, digitization, and scale in hybrid breeding, shifting from an empirical, manpower-driven model.

02 Technical Details: The AI-Powered "Three-in-One" Approach

Quick Access to Core Data:

To enable robots in greenhouses, the team first solved the "seeing clearly" issue. They collected 12,800 tomato flower images from real environments, annotated flower bounding boxes, segmentation masks, and orientation features. This dataset trained the deep learning model, enabling stigma recognition under foliage and varying lighting conditions. In complex environments, the model achieves 85.1% stigma recognition accuracy, approaching human levels.

Figure: Crop flower reshaping and AI robot collaborative design for intelligent automated hybrid breeding

Recognition paves the way for "action." When the robot locks onto a flower, a flexible brush on its arm extends into the flower, simulating natural pollen vibration. This 15-second process is faster, more standardized, and consistent than manual labor. Single cruise pollination success rates are 77.6% ± 9.4%, with multiple cruises matching or exceeding manual fruit set rates.

Jieer achieves large-scale, repeatable pollination control, transforming "empirical" into "algorithmic."

This process relies on three core modules:

Visual Perception Module: High-resolution multispectral cameras with inertial navigation sensors collect greenhouse scenes in real-time. The AI model detects flowers, segments masks, and determines stigma orientation at millisecond speeds, achieving millimeter-level precision.

Decision Control Module: Sensors and LiDAR coordinate to plan the optimal cruise route during "recognition - localization - contact," matching greenhouse production rhythms and avoiding missed flowers or repetitions.

Mechanical Execution Module: The robotic arm features a flexible brush and collision detection system. It enters flowers with slight vibrations, efficiently transferring pollen while preventing damage. Force control strategies ensure "flexibility without weakness."

The system travels freely between greenhouse aisles, forming an integrated loop from image recognition to pollination. The process involves:

1. Recognition: The camera captures images, and the AI model selects flowers in the pollination window.

2. Localization: The algorithm calculates the robot-flower relative position, with LiDAR aiding path planning.

3. Contact: The robotic arm extends into the flower, and the flexible brush completes pollination.

"Jieer" Intelligent Breeding Robot (provided by the research team)

For unattended operation, Jieer robots feature an edge computing platform (e.g., onboard GPU or embedded AI box) running visual models and path planning locally for real-time decision-making.

The team also built a greenhouse digital twin system: based on 3D modeling and sensor data, it creates a virtual mirror image, optimizing the robot's cruise path and task scheduling in a simulated environment. This verifies parameter configurations, achieving the shortest path and high coverage, supporting Jieer's stable operation.

A major highlight is Jieer's highly localized hardware system, with over 95% of components sourced domestically. This includes key drive motors, harmonic reducers, force sensors, high-precision cameras, etc. Domestic brands like Jingke, Yongjin, and Shangbang provide harmonic reducers, while multiple domestic servo systems meet agricultural robots' micron-level positioning accuracy. In image processing, Chinese AI chips and embedded computing modules from Cambricon and Huawei Ascend are also applied. High localization reduces costs, enhances supply chain controllability, and facilitates maintenance, supporting Jieer's upgrades and large-scale promotion.

03 Commercial Greenhouse Validation: Efficiency and Cost Comparison

In commercial greenhouse tests, Jieer robots performed close to or even surpassed skilled workers. Data shows that on soybean materials with exposed stigmas, robot pollination saves about 76.2% of manual time, with more standardized and consistent actions. This means higher tasks per unit time and avoids human fatigue or experience-related instability. At 15 seconds per flower, one Jieer's daily workload equals several workers combined, especially critical amid ongoing labor shortages.

Economically, though Jieer's selling price is in the hundreds of thousands, its payback period is a few years considering long-term labor substitution. As service life extends and seed production scales, unit costs further decrease. Importantly, it alleviates rural labor aging and rising costs, stabilizing breeding enterprises' costs. Post-application, not only does breeding productivity increase, but hybrid breeding success rates and variety consistency also improve, enhancing overall seed production efficiency.

This transformation benefits not just individual enterprises but the entire industry. Manual pollination accounts for over 25% of tomato hybrid breeding costs, with global hybrid breeding expenditures nearing 100 billion yuan. Jieer's introduction could reduce at least a quarter of these costs, not just saving labor expenses but potentially accelerating variety development cycles and shortening new variety time-to-market. This efficiency boost directly impacts China's and the global food supply chain's resilience.

Policy and capital are also accelerating this process. The Ministry of Agriculture and Rural Affairs emphasizes intelligent agricultural machinery promotion. Intelligent pollination robots align with this policy and could be included in agricultural machinery purchase subsidies or demonstration projects. In the capital market, companies like Israel's Arugga and Singapore's Polybee have received multiple funding rounds based on pollination robots. Jieer's launch signals domestic capital's focus on "AI + agriculture," potentially attracting new startups and accelerating industry chain maturity.

In essence, Jieer transforms not just a single link but reshapes agriculture's professional ecology and industrial logic.

04 Global Solutions: Similar Problems, Diverse Approaches

Supported by a comprehensive hardware and algorithm system, Jieer demonstrates strong engineering capabilities. Globally, automated pollination exploration extends beyond China, with research teams worldwide experimenting with different paths.

Israel's Arugga company has pioneered the "Polly" robot, a groundbreaking advancement in commercial robotics. Leveraging AI vision to identify flowers, Polly employs high-pressure airflow to mimic bee vibration pollination, circumventing the labor-intensive process of manual pollen brushing and operating independently of live insects, even in fully artificial lighting conditions. According to public data, Polly's implementation in tomato greenhouses has boosted yields by approximately 3-7% while significantly reducing labor costs. However, it still requires manual transportation to each planting line, indicating that full automation remains a work in progress. Future research aims to achieve true autonomous navigation. Supported by the NVIDIA Jetson platform, Polly's AI model continuously evolves to adapt to changes in greenhouse lighting and crop varieties.

Researchers at West Virginia University in the United States have introduced a novel concept: multi-arm parallel operation. Their "StickBug" robot is equipped with six robotic arms, some dedicated to securing branches and others to vibrating for pollination. This method excels in its high concurrency, enabling simultaneous pollination of multiple crops. However, due to the complexity of the robotic arms and the nascent stage of greenhouse mapping and multi-arm coordination algorithms, the system is currently confined to laboratory settings and not yet ready for commercial deployment.

Singapore's Polybee team has opted for a drone-based approach. Their small drones utilize downward airflow from propellers to vibrate flowers, thereby facilitating pollination. Polybee's strength lies in its flexibility, operating independently of fixed tracks and adapting to greenhouses with multi-layer or complex layouts. This solution has undergone pilot testing in Australia, demonstrating stable pollination results. Nonetheless, drones face limitations in endurance, battery replacement, and flight safety, necessitating further verification for stable deployment in large-scale greenhouse environments.

In contrast to these solutions, Jieer stands out with its "crop-robot collaborative design." The research team has employed gene editing to tailor crop flower shapes for seamless robotic arm operation, enabling efficient pollination with a single-arm brush without relying on complex aerodynamics or multi-arm coordination. This design approach shifts complexity to the crop itself, creating a more stable and closed-loop solution. Each flower is pollinated in just 15 seconds, allowing for continuous operation throughout the day with efficiency rivaling or surpassing manual labor, achieving true closed-loop automation from recognition to localization and pollination.

From the lab to the greenhouse, the "Jieer" robot demonstrates that the long-standing challenge of manual pollination is being reshaped.

Behind this transformation lies the profound integration of biotechnology and artificial intelligence, marking a significant breakthrough in China's agricultural modernization and seed industry independence.

Globally, various approaches to manual pollination are still being explored, with Jieer pioneering the closed-loop system through its "crop-robot collaborative design."

Who will emerge as the frontrunner in this competition hinges on technology maturity and industrialization speed. One thing is certain: the era of automatic pollination has dawned.