How Does 48V Technology Propel the Evolution of Robots?

![]() 11/05 2025

11/05 2025

![]() 517

517

Produced by Zhineng Technology

The robotics industry stands at a pivotal crossroads where intelligence and electrification converge. From industrial robots to collaborative robots, and further extending to personal and service robots, the evolution of power architectures has emerged as a pivotal factor in enhancing performance and reliability.

The 48V power supply system, distinguished by its safety, efficiency, and minimal losses, is steadily supplanting the traditional 12V architecture as the new benchmark for diverse robot designs. This transition not only reshapes the design philosophy of robot motor drive systems but also spurs the optimization and modernization of the entire robot industrial ecosystem.

01

The Robotics Industry and Power Systems

The ascendancy of robotics technology is a cornerstone of the Fourth Industrial Revolution. According to data from the International Federation of Robotics (IFR), by 2018, nearly 2.5 million industrial robots had been deployed worldwide, with an annual growth rate surpassing 400,000 units.

The automotive and electrical electronics sectors are the primary adopters, accounting for over half of the total deployments. They are closely followed by metal processing, plastics, chemicals, and the food and beverage industries. Approximately 75% of industrial robots are concentrated in China, Japan, the United States, South Korea, and Germany, indicating a high degree of geographical concentration and industrial maturity.

The service robot market is also witnessing rapid expansion. Professional service robots are predominantly utilized in manufacturing and logistics, while personal and household robots are experiencing similar growth rates, primarily applied in vacuuming, education, and research, with a rapidly expanding market size and social penetration.

Amidst this evolution, innovation in power architectures has become instrumental in shaping the future of robotics.

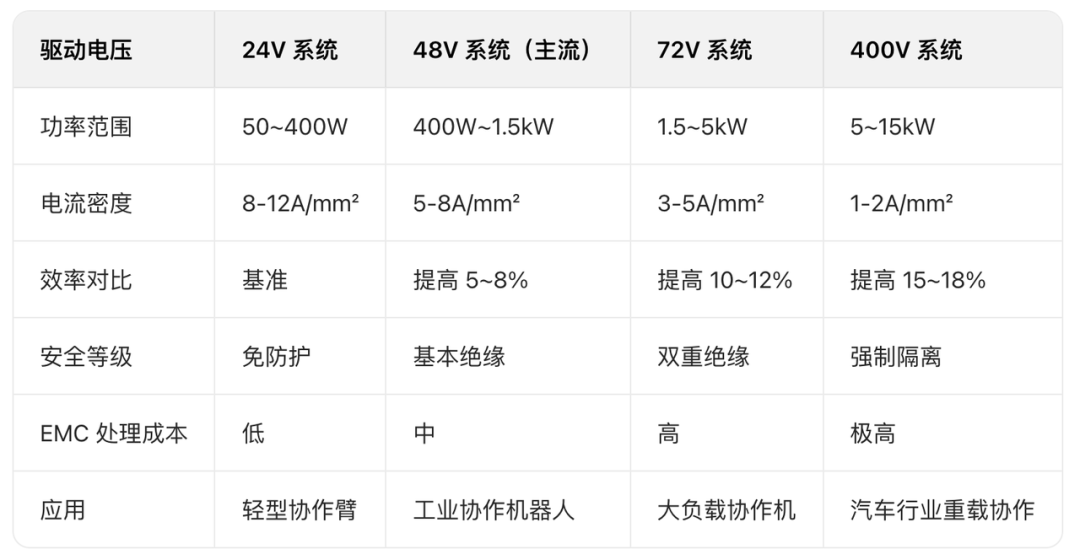

Traditional robot power supply systems typically employ a 12V DC power method. While simple and reliable, this approach gradually reveals limitations in terms of energy density, system weight, and cost control. As robots progress towards higher integration, lighter structures, and greater flexibility, the 48V system has emerged as a new industry trend, replacing the 12V architecture.

The 48V voltage is recognized as the highest universal safe voltage, mitigating safety risks associated with high voltage while substantially enhancing power transmission efficiency. Compared to a 12V system, a 48V system can reduce conductor size by one-fourth and power losses to one-sixteenth of the original, offering significant weight and energy efficiency advantages.

For collaborative robots requiring high dynamic response and extended endurance, this translates to smaller motors, lighter joints, and enhanced system reliability.

The widespread adoption of the 48V architecture is not solely driven by demand from the robotics industry but also benefits from mature experiences in other sectors.

◎ In the automotive industry, 48V systems have been extensively utilized in start-stop systems, electric compressors, and electronic steering systems.

◎ In data centers and cloud computing equipment, 48V DC buses have become the mainstream power supply solution for server backplanes and cooling systems.

The large-scale applications in these fields have matured the supply chains for 48V power modules, converters, power chips, and magnetic components, providing reliable and cost-competitive solutions for the robotics industry.

02

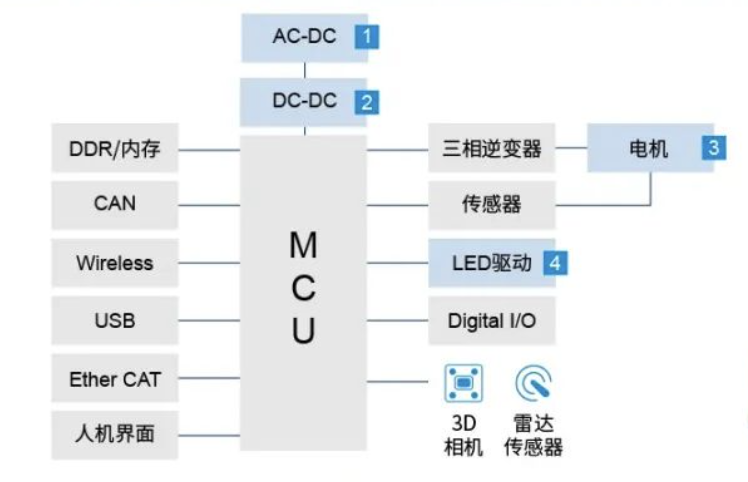

48V Robot Drive Architecture and Key Components

As a significant branch of industrial robots, collaborative robots have rapidly gained popularity in automotive manufacturing, healthcare, electronic assembly, and other fields due to their flexibility, safety, and ease of operation. They are no longer confined to 'isolated devices' on closed production lines but have evolved into 'intelligent partners' working alongside humans.

These robots necessitate high-precision sensing, high-dynamic control, and real-time responsiveness, imposing stringent demands on the energy efficiency and stability of the power supply system.

The motor drive system of collaborative robots is a pivotal component responsible for converting control signals into precise mechanical actions.

This system typically encompasses modules such as multi-phase motor drivers, DC-DC power conversion, current detection, inductive filtering, and battery management. Previously, systems operating under the 12V architecture often encountered issues like excessive current, leading to wire heating and efficiency degradation.

The introduction of the 48V motor drive system enables engineers to reduce cable sizes, lower heat losses, and simplify system protection designs, thereby enhancing overall energy efficiency and integration.

In terms of power architecture, modern collaborative robots predominantly adopt a 48V bus system.

◎ Stationary robots are typically powered by mains electricity, which is converted to 48V DC after passing through a power factor correction (PFC) circuit.

◎ Mobile robots, such as logistics AGVs, inspection robots, or nursing assistants, are powered by 48V battery systems and maintained through regular charging.

For semiconductor components, most logic circuits and sensor modules cannot directly withstand 48V voltages, necessitating the use of buck converters (DC-DC) to step down the voltage to 5V or even lower levels.

Currently, there are two mainstream solutions:

◎ One approach is to adopt an Intermediate Bus Architecture, initially stepping down 48V to 12V, and then utilizing Point-of-Load (PoL) converters to output to various modules.

◎ The other approach is to adopt a single-stage buck solution, directly converting from 48V to the target voltage.

The latter is gradually becoming the preferred choice for high-performance robot designs due to its reduced energy conversion steps and improved system efficiency.

Inductors, as pivotal components in the 48V motor drive system, directly influence the stability and energy efficiency of the entire power supply chain.

Inductor designs with high saturation current, low DC resistance, and minimal losses can significantly reduce thermal losses in DC-DC converters and suppress electromagnetic interference from high-frequency switching noise on sensitive modules like image sensing and position sensing. For high-frequency switching scenarios, inductors utilizing materials like iron powder cores and alloy powder cores have become mainstream choices.

The promotion of the 48V system in collaborative robots also opens up new avenues for modularity and maintainability.

For instance, drawing inspiration from the eFuse design in cloud computing equipment, robots can achieve module-level power protection and hot-swapping during operation, enhancing reliability and scalability. This architecture enables robots to dynamically switch tool-end modules (such as grippers, welding guns, cameras, etc.) for different tasks without requiring complex system restarts and reconfigurations.

Summary

From industrial robots to collaborative robots and onto future intelligent service robots, innovations in power technology are reshaping the entire industrial landscape. The 48V system not only strikes a balance between performance, safety, and cost but also serves as a crucial enabler for enhancing energy efficiency and structural lightweight in robots.