The Chinese mainland iPhone 17 is not made in India, finally putting Apple fans' hearts at ease

![]() 08/22 2025

08/22 2025

![]() 634

634

Source: SourceByte

A migration is unfolding.

On August 19, Bloomberg's renowned journalist Mark Gurman dropped a bombshell: India will produce the full iPhone lineup for the first time. In the future, all iPhones sold to the United States will depart from the port of Chennai, India, and cross the ocean.

As a seasoned media veteran who has followed Apple for years and achieved almost 100% accuracy in leaks, Mark Gurman's news immediately sparked discussions about "curry-flavored iPhones" on social media.

Even without this leak, the weight of Made in India has been increasing within Apple's system. According to a Canalys report, in the first half of 2025 alone, the number of iPhones produced in India reached a staggering 23.9 million units, a year-on-year increase of 53%. Among the total global iPhone production, "Made in India," which was once negligible, now accounts for 16% to 17%.

Apple's goal is to increase this figure to 25% by 2027.

One-quarter.

This is a figure that can keep any Chinese "Apple supply chain" enterprise up at night. From March 2024 to March 2025, the total value of iPhones assembled in India reached $22 billion, a near 60% year-on-year surge.

When Cook tries to replicate China's "Apple supply chain miracle" in India, is he facing a new continent full of opportunities or a "battlefield" riddled with traps?

01

Cook's Dilemma

On April 18, 2023, Apple CEO Tim Cook smiled like a child at the opening of Apple's first retail store in Mumbai.

Screenshot from Apple's official website

He personally pushed open the glass door to greet the already boiling crowd outside. Flashlights, cheers, everything seemed to bring back memories of Beijing's Sanlitun in 2008. At that moment, what Cook saw was perhaps not only the huge potential of the Indian market but also a reflection of Apple's next golden decade.

The decade from 2008 to 2018 can be described as Apple's golden decade in China, and replicating China's success in India is not impossible.

During the conference call after the financial report was released at that time, the word "India" was mentioned by Cook more than 20 times: "The Indian market is very exciting, and the vitality there is incredible."

Data supports this excitement: When revenue in Greater China, where Apple relies for survival, fell by 2.89% year-on-year, other regions of Asia-Pacific, including India, achieved a counter-cyclical growth of 15%, reaching $8.119 billion.

But the other side of the story is helplessness.

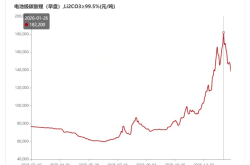

When tensions over China-U.S. tariffs were at their peak, the Trump administration issued an order imposing cumulative tariffs of up to 104% on China. Upon the news, Apple's stock price plummeted, and its market value evaporated by nearly $640 billion in 72 hours. Across the ocean, leading Chinese "Apple supply chain" enterprises such as Luxshare Precision and GoerTek suffered three consecutive daily limits.

When one prospers, all prosper; when one falls, all fall.

Morgan Stanley predicted at the time that this round of tariffs could cost Apple up to $33 billion in annual losses, equivalent to 26% of its fiscal year operating profit.

Unprecedented policy pressure made Cook restless. The National Legal and Policy Center (NLPC) even publicly launched a campaign accusing Apple under Cook's leadership of "over-reliance on the Chinese supply chain" and calling on shareholders to "oust Cook."

Political pressure and market fear weighed heavily on Cook's shoulders like two mountains. More than 80% of iPhones are still manufactured in Chinese factories, a figure that once made Cook proud but now represents his greatest "original sin."

He had no choice but to find a "backup" within a short period, a Plan B that could hedge risks and reduce dependence.

Long before the tariff storm officially hit, Apple had already begun its layout. According to The Times of India, Apple urgently used five cargo planes to transport iPhones and other products worth possibly up to 600 tons from India to the United States. A supply chain director bluntly stated during an internal meeting: "This is a race against time. Every day of delay costs the U.S. warehouse $8 million."

Thus, Cook turned his gaze to India. This land that once changed Jobs' life has now been given a new mission by Cook: to replicate China's "Apple supply chain miracle."

In April 1974, 19-year-old Jobs arrived in India, officially beginning his seven-month spiritual journey, achieving enlightenment, and fundamentally rewriting the underlying logic of technology history.

Cook does not possess Jobs' genius inspiration; he excels in precision calculations. In India, Cook adeptly employs his signature balancing act, which is typically "supporting one and restraining another." In China, he supported Luxshare Precision, successfully counterbalancing Foxconn's bargaining power. Now in India, he has chosen the local giant Tata Group, attempting to replicate this strategy.

There is both a desire for the future and a fear of the present, reflecting Cook's contradictions and dilemmas in India.

02

Cook Has No Choice

However, India does not believe in "miracles."

It only believes in reality, a nearly brutal reality.

Before Cook outlined his blueprint for India, a group of Taiwanese "Apple supply chain" contract manufacturers had already arrived as pioneers, receiving a brutal education in realism on this land. Their experiences are a testament to "acclimatization issues."

Wistron is the most typical example.

This core Apple contract manufacturer spent $700 million to build a modern factory in Bangalore, India, with ambitious plans to make a big splash. However, instead of orders, it was met with continuous troubles: factory strikes, worker unrest, frequent fires... Eventually, after exhausting its patience and money, Wistron chose to "cut its losses" and leave.

Taking over was India's "favorite son," the Tata Group, known as India's version of Samsung. The transaction price was $125 million, less than 20% of the total investment.

If the Samsung Group is a witness to the life trajectories of Koreans, then the Tata Group is a panoramic footnote to Indian life.

Tata Group LOGO

A typical day for an Indian usually goes like this: After waking up in the morning, they leisurely brew a cup of Tata tea and then drive to work in a car produced by Tata. The electronics they use at work may also be manufactured by Tata, and even the software is developed by Tata. At lunchtime, they buy lunch from a supermarket owned by Tata. When they return home from work, all the household appliances they use are also from Tata.

Pegatron's fate was similar. It also responded to Apple's call, invested heavily, and struggled to deal with various bizarre incidents. Its factory in Chennai even caught fire in September 2023, causing iPhone assembly operations to be suspended for a time. Ultimately, it also reluctantly handed over control of the factory to the Tata Group.

There is no way around it; foreign enterprises on Indian soil often encounter various accidents, and it has been dubbed the "foreign capital graveyard" by the outside world.

Cook could not be unaware of these situations. But he had to try; the pressure from geopolitical games forced him to accept everything about Made in India, even if quality control was a nightmare.

A report by the Financial Times stated that at an iPhone components factory operated by the Tata Group, only one out of every two components is intact.

In other words, the yield rate is only 50%.

For a company that believes in "zero defects" and can trend on social media for even a small flaw on the phone frame, such a yield rate is indeed unacceptable. Taiwan's "China Times" even reported that hygiene management issues at Indian factories have led to excessive levels of E. coli in products.

Efficiency is also a concern. The efficiency of Foxconn's factories in India is only 55% of that of its factories in Zhengzhou, China. Some teardown videos have even revealed various low-level flaws in iPhones assembled in India: fingerprints clearly visible on the motherboard, dust inside the camera.

Beyond hardware, the problem of people is even more intractable.

In Indian factories, female workers earn 30% to 40% less than male workers. The lack of a "wolf culture" among Indian workers also frustrates managers accustomed to Chinese speed. Xiaomi engineers once shared a story that left them both amused and exasperated: They specifically wrote an English tutorial to familiarize Indian workers with the operations, only to find out later that many workers could not understand English due to the numerous official languages in India.

Later, Foxconn withdrew more than 300 experienced Chinese engineers from its Indian factories, attempting to replace them with local talent. Analysts believe that this move will inevitably lead to a further decline in production efficiency in the short term.

But Apple seems to be in a hurry.

A management official at Foxconn's Indian park once said something meaningful to the media: "During the off-season, production reductions also affect Chinese capacity, while India operates at full capacity."

Behind these words lies Cook's helplessness in choosing inefficient "full capacity" over supply chain security. This is no longer a commercial calculation but a political survival question.

03

Differentiation of the "Apple Supply Chain"

Apple's migration directly disrupts the waters of "Apple supply chain" enterprises.

The most aggressive is Foxconn. As Apple's largest contract manufacturer, Terry Gou's choice is "wherever the gambling table is, that's where I am." It not only plans to increase its workforce in India from 100,000 to 200,000 but also announced in May 2025 that it would invest an additional $1.5 billion in its Indian subsidiary.

However, mainland Chinese "Apple supply chain" enterprises are much more cautious.

Wang Laichun, chair of Luxshare Precision, who rose from the Foxconn assembly line to become the "wealthiest woman in Chaoshan," was quite calm when talking about India: "We need to be cautious. After all, India is different from China, and the improvement of its industrial chain ecology is related to national construction and talent cultivation."

GoerTek also made it clear that it currently has no specific plans to set up a factory in India. The head of Yuto Technology in India even bluntly stated that Indian customs and other departments often require enterprises to submit materials within a day, increasing a lot of hidden costs.

Although they appear cautious on the surface, underneath, they have embarked on a more aggressive capital exodus aimed at hedging "Apple risks."

2025 became the "capital operation year" for China's "Apple supply chain."

On August 18, Luxshare Precision officially submitted a listing application to the Hong Kong Stock Exchange, planning to raise more than $1 billion. The prospectus clearly mentions that one of the uses of the fundraised capital is to "invest in high-quality targets in upstream and downstream industries or related industries."

Before submitting the application, Luxshare had already embarked on a series of dazzling mergers and acquisitions: In March, it acquired WTD's ODM business for 4.389 billion yuan, expanding from pure "contract manufacturing" to upstream product integration; earlier, it also spent 525 million euros to acquire the German century-old automotive wire harness manufacturer Leoni.

Similarly,""On July 9, "Glass King" Lens Technology officially listed in Hong Kong, raising HK$4.768 billion. On July 21, GoerTek Microelectronics, a subsidiary of GoerTek, also submitted a listing application to the Hong Kong Stock Exchange.

The "Big Three" of the "Apple supply chain" gathered at the Hong Kong Stock Exchange in 2025.

These "Apple supply chain" enterprises are leveraging Hong Kong's international capital platform to stockpile ammunition for themselves and search for a "second curve" beyond Apple. Automotive electronics, communications and data centers, XR, and other conceivable fields have become their new battlegrounds. Luxshare Precision's financial report shows that the revenue of its automotive electronics, communications, and data center business lines has a compound annual growth rate of 49.6% and 19.6%, respectively.

The reason they have the confidence to carry out such large-scale capital operations stems from the fact that China's "trump card" is still in play. An unavoidable fact is that India still plays the role of the terminal assembler who "tightens the screws last."

Currently, more than 80% of Apple's 200 major global suppliers have factories in China engaged in Apple-related production.

"China is a core part of our supply chain, where we have invested for 30 years. We will always be here - I don't think this will change, and we will continue to make large-scale investments in China," said Apple Chief Operating Officer Jeff Williams.

In other words, chips, sensors, displays, cameras, almost all key components used in iPhones produced in India still need to be transported long distances from China to India.

More importantly, the highly integrated, extremely responsive, and highly executable manufacturing culture and industrial ecosystem that has been formed after decades of precipitation, with hundreds of billions of dollars invested by Apple and training of over 28 million workers, cannot be replicated in the short term.

Equipment in Foxconn's factories in India usually comes from China, and all standard operating procedures, work instructions, commands, and software are only available in Chinese, "even the 'emergency button' is written in Chinese."

That is the "soul" of China's manufacturing industry.

For now, even if the iPhone box says "Made in India," this globally iconic consumer product still cannot do without China.

Some images are sourced from the internet. Please inform us if there is any infringement for deletion.