From 'Going Out' to 'Steady Going': Revolutionizing Supply Chain Resilience for Chinese Enterprises' Overseas Expansion

![]() 08/04 2025

08/04 2025

![]() 618

618

When overseas enterprises can confidently rely on a comprehensive network to focus on "how to sell better" rather than worrying about "whether the goods can arrive," they have truly made the leap from merely "going out" to "steady going." The heart of this transformation lies in cultivating a resilient, full-link supply chain—a strategic cornerstone not just for logistics but for brands to take root and compete long-term in international markets.

Original creation by New Entropy's Overseas Economy Team

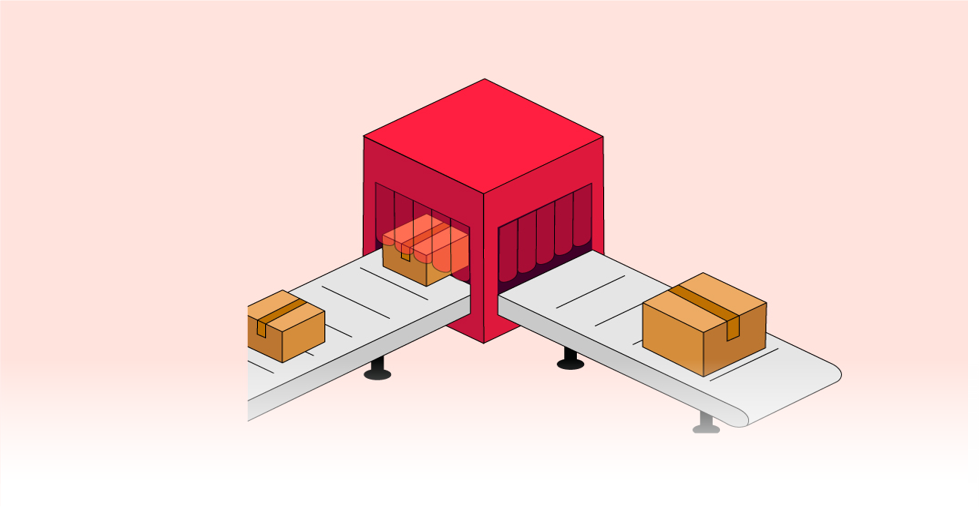

In recent years, Chinese enterprises' presence in overseas markets has evolved beyond the "Made in China" label. From SHEIN redefining fast fashion to Anker Innovation becoming a silent giant in 3C on Amazon, to Mixue Bingcheng opening thousands of stores in Vietnam, Chinese enterprises are transitioning from traditional "product export" to a deeper "brand cultivation" strategy amidst expanding cross-border trade. However, this transformation is not without challenges. The previous reliance on fragmented logistics services is strained in today's increasingly complex global market. Hence, a stable, efficient, and reliable cross-border full-link supply chain network encompassing "domestic collection - cross-border transportation - overseas warehousing and distribution - last-mile delivery" has become crucial for enterprises to shift from "selling products" to "operating markets" and truly establish themselves overseas.

Core foundation of a fully visible and controllable resilient supply chain

The core of Chinese enterprises' desire to build a stable and reliable overseas supply chain lies in achieving "full-link visibility and control." This involves creating an intelligent network that seamlessly integrates "domestic collection - cross-border efficient transportation - overseas intelligent warehousing and distribution - local last-mile delivery," dismantling the traditional "black box" of cross-border logistics. However, the reality is that goods shipped from China to overseas must traverse multiple logistics nodes, customs supervision, and diverse market environments. Any poor connection or inadequate localization in these links can lead to delays, soaring costs, and even compliance risks. Different countries have varying regulations on product access, labeling, taxation, and logistics infrastructure, posing dual challenges of "cross-link collaboration" and "localization adaptation" in supply chain management. This requires logistics enterprises to not only bridge the physical and information gaps between domestic warehousing and cross-border transportation but also deeply integrate local warehousing and distribution networks with cross-border trunk lines, ensuring swift and accurate delivery to end consumers. Best Inc.'s cross-border full-link supply chain network exemplifies this approach. Taking Changhong Electric's Southeast Asia expansion as an example, Best Inc. handles transportation to various countries, including import customs clearance, integrated overseas warehousing and distribution, delivery to customer terminals, and even installation services. This "one order to the end" model simplifies Changhong Electric's supply chain management, reduces costs, and enhances user experience and sales through Best Inc.'s local warehousing and distribution capabilities in Southeast Asia. The key lies in "system integration"—through OMS, WMS, and TMS, customers can track their goods' status from order generation to delivery, making the supply chain highly visible and reducing traditional cross-border parcel costs and risks.

Moreover, full-link resilience is vital in emergency responses. For instance, during temporary port control, inventory linkage between domestic and overseas warehouses can swiftly switch to "maritime to land transportation" to ensure order fulfillment. The essence of supply chain resilience is the fusion of "resource redundancy" and "system flexibility," achievable through logistics enterprises' long-term cultivation, Best Inc.'s strength.

Forging Resilience

A Mesh Ecosystem to Mitigate Risks and Achieve Long-Term Success

Geopolitical factors have led to frequent "cross-border black swan" events, causing capital chain disruptions due to unsold overseas inventory. However, enterprises with a "China - Southeast Asia - North America" multi-warehouse linkage can quickly reallocate inventory and resume sales. This underscores the difference in supply chain resilience: the former is linear, while the latter is a mesh ecosystem. Supply chain resilience stems from the synergy of collection, warehousing, and last-mile delivery, not a single link's strength. Based on this, Best Inc. has pioneered a "golden logistics triangle" with China, Southeast Asia, and North America as cores, responding to the "Belt and Road" initiative to form a B2B2C and cross-border business network connecting manufacturing, consumption, and transit hubs. This multi-regional, multi-path collaboration strategically addresses global uncertainties.

This architecture's depth lies in China as the global supply chain's source and digital innovation engine, Southeast Asia as the fulcrum for high-growth emerging markets, and North America as the strategic node for mature markets, forming an interconnected global cross-border supply chain network. Best Inc. coordinates express delivery, supply chain, international, and software segments to create a global end-to-end integrated supply chain service platform, anchored by a digital system (OMS, WMS, TMS) for full-link visibility and control from factory to consumer. Best Express handles domestic collection and consolidation; Best Cross-Border manages customs clearance and international transportation; the overseas segment (Best Supply Chain + Best International) undertakes warehousing and local distribution; and the local last-mile network directly connects with end users. Embedded finance, taxation, and compliance services address localized operational pain points. This "logistics + information flow + value-added services" model transcends traditional cross-border service fragmentation. An efficient, stable, and deeply localized cross-border full-link supply chain network enables enterprises to swiftly respond to market changes, accurately reach target consumers, and effectively manage inventory and orders, enhancing operational efficiency and customer satisfaction. This confirms: only when the supply chain penetrates the target market like 'capillaries' can enterprises truly transition from "selling products" to "operating markets."

The Last Mile: Decisive for Final Success

The last-mile delivery, the crucial link between brand and consumer, significantly impacts user experience and brand impression. In fiercely competitive overseas markets, consumers demand timely logistics, package integrity, friendly delivery service, and flexible payment methods. A seamless last-mile experience enhances consumer satisfaction and loyalty, potentially catalyzing brand word-of-mouth. Conversely, issues like delays, damage, or poor service can lead to complaints, negative reviews, and irreparable brand damage. Thus, for Chinese enterprises aiming to deeply cultivate overseas brands, prioritizing and continuously optimizing the last-mile link is vital for enhancing user stickiness and building a brand moat. This requires enterprises to invest in localized last-mile networks while ensuring cross-border transportation efficiency, meeting or exceeding local consumers' expectations.

The core challenge of the last mile lies in "localization barriers"—infrastructure, consumption habits, policies, and regulations differ vastly across markets. For instance, Vietnam's uneven urban-rural road conditions demand familiarity and vehicle adaptability from last-mile teams. Vietnamese consumers prefer cash on delivery (COD), necessitating robust cash management and delivery efficiency. In Thailand, consumer protection-oriented policies allow pre-payment inspection, and quality issues can lead to refusal and refunds. Courier companies must temporarily store COD payments for five days before transferring them to sellers. In Malaysia, communication during package sign-offs and respecting local religious customs under a multicultural background also affect consumer satisfaction. These pain points highlight the value of local networks. Facing Southeast Asia's complex market environment and relatively weak logistics infrastructure, Best Inc. adopted a "logistics infrastructure first + localization of digital and intelligent experience" strategy. By successfully localizing China's mature logistics experience and digital models, Best Inc. created a seamless connection from domestic to Southeast Asian warehouses. In Vietnam, since 2019, Best Inc. has built a nationwide express network with a daily package handling capacity of 1.8 million pieces. With 39 express distribution centers equipped with automated assembly lines spanning over 100,000 square meters, sorting efficiency has quadrupled, accuracy reached 99.9%, and package damage is minimal (below 0.01%). This not only improves logistics timeliness but also guarantees end-consumer experience, earning local trust for overseas brands.

In Malaysia, Best Inc.'s extensive network of over 90 terminal outlets covers major cities and towns nationwide, offering not only standard express services but also catering to diverse delivery needs, ranging from small e-commerce packages to large household items. This is achieved through the integration of 'express + less-than-truckload + full-truckload' transportation resources. Furthermore, Best Inc. has pioneered large-item express delivery services in Malaysia, linking with China's domestic express delivery network to provide end-to-end solutions for customers needing to transport bulky goods. By the end of 2024, Best Inc. had established 35 self-operated express distribution centers, over 1,500 service outlets, and overseas warehouses spanning over 300,000 square meters in Southeast Asia. This deeply localized network and diversified service offerings enable Best Inc. to better adapt to the complex and varied market demands across Southeast Asia, effectively tackling the challenges of last-mile delivery, thereby significantly enhancing consumer shopping experiences and providing robust logistical support for the expansion of Chinese brands in the region. Notably, last-mile services are evolving into 'value-added links in the supply chain,' where logistics providers transcend their traditional role as cargo handlers, offering brands more diverse and customized services through their extensive last-mile network and profound understanding of local market demands, thereby generating additional commercial value. For instance, in the overseas warehousing and distribution services for a leading sports brand in Southeast Asia, Best Inc. not only provides fundamental services like warehouse-to-store and store-return-to-warehouse but also enables 'flexible switching between large-item and full-truckload delivery' via its last-mile network. This approach, grounded in a deep comprehension of local market demands, aids brands in managing inventory more efficiently, responding to market changes swiftly, reducing logistics costs, and enhancing operational efficiency. For overseas brands, leveraging differentiated logistics services to boost brand competitiveness in the target market and transforming logistics links into brand touchpoints signifies grasping the initiative in the last mile and shaping consumer experiences, thus securing a more advantageous position in the fiercely competitive market.

Conclusion: As we enter 2025, overseas competition has entered a new phase of 'intensive cultivation.' The value of the supply chain has long surpassed mere 'logistics transportation,' becoming an integral part of a brand's global competitiveness. Choosing a 'full-link partner' is choosing 'certainty' for overseas ventures. When overseas enterprises can rely on a full-link network to focus on 'how to sell better' rather than 'whether the goods can arrive,' they have truly achieved the transition from merely 'going out' to 'steadily going out' – this is the ultimate value of supply chain resilience.