Will Trump back down?

![]() 04/14 2025

04/14 2025

![]() 565

565

Text / Shi Jie

Source / Jiedian Finance

Political polarization has spread from Capitol Hill to Wall Street, penetrating from ballot boxes to steering wheels as Trump tears open the rift in the United States.

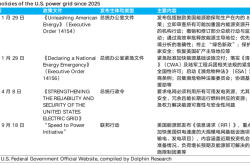

Recently, the Trump administration announced increased tariffs on multiple countries. Steel, aluminum, automobiles, chips, and even upcoming tariffs on pharmaceuticals have become Trump's "targets of fire".

Among the industries hit hardest, the automotive industry bears the brunt. Previously, Trump announced a 25% tariff on all foreign-made cars, tearing a crack in the highly collaborative supply chain system of the automobile industry. Since then, he has suspended tariffs on most countries for 90 days but still retained a general tariff of 10%.

As Trump's biggest supporter, Musk, who has always cheered from behind Trump, can no longer hold on. Under this policy, Tesla has become the American company most impacted by tariffs.

All people in the world strive for benefits.

Since the beginning of this year, Tesla's share price has fallen by nearly 37%, more than 50% from its historic high on December 17, 2022. The struggle for interests is causing Musk and Trump to drift apart.

Tesla and Musk are merely a microcosm of the tariff war. Consumer goods, healthcare, agriculture, industry, manufacturing, and other industries are all caught in this hurricane.

01 A Simple Arithmetic Problem

Tariffs are taxes imposed on imported goods.

Take Apple's iPhone as an example: If China manufactures an iPhone for Apple, it needs to declare the overseas production cost to the U.S. government. Assuming an iPhone sells for $100, with a 54% tariff, Apple must pay the Chinese factory $100 and an additional $54 to the U.S. government.

A simple calculation: Previously, an iPhone cost $100, but now it has directly risen to $154. However, companies cannot do business at a loss, so Apple doubles the cost to sell to distributors, who then double it again to sell to consumers.

Currently, 90% of Apple's iPhones are assembled in China. Reuters has analyzed that if the tariff cost is fully passed on, the price of the iPhone 16 Pro Max in the U.S. will soar from $1,599 to $2,300, about RMB 16,700, with a single phone price increase of over RMB 5,000.

Morgan Stanley's latest report points out that the average price of Apple products may increase by 17% to 18% as a result. Taking the iPhone 16 series as an example, the base model may rise from $799 to $950, with an even greater increase for the Pro series, putting consumer purchasing power to the test with a "cliff-like" drop.

But the crux of the matter is, will manufacturing return to the United States after imposing tariffs? The answer is no, as the production cost in the U.S. is higher than in China even after adding tariffs.

Molson Hart, CEO of U.S. consumer goods company Viahart, is a seasoned toy manufacturer. He explained with his personal experience: His company produces a Lego-like plug-in toy called "Snowflake", but the tricky part is that it is almost impossible to find mold repair technicians in the U.S. They have either passed away or retired. Once the mold is damaged, it has to be reordered from China, halting production for several months.

He bluntly stated that people often underestimate the complexity of manufacturing, but the reality is harsh: If you can't even master the technology, no matter how high the tariffs are, they can't force out "Made in America". For example, Apple can design the iPhone but may not be able to produce all its components.

Not only high-end manufacturing but also in recent days, egg prices in the U.S. have soared, with some areas implementing rationing on eggs. This already shows that the tariff dispute is indeed affecting the rights and interests of every citizen.

In fact, U.S. agricultural development is limited by seasons and growing conditions. Some American companies grow agricultural products, including tomatoes and avocados, in Mexico and other places and then sell them in the U.S., but they face import tariffs as a result.

And it is not easy to immediately move agricultural production back to the U.S.

Rudolph Spielmann, CEO of Natural Sweet, said that building greenhouse infrastructure in the U.S. would require years and billions of dollars, as well as a comprehensive reform of immigration laws to ensure sufficient labor. Most of the company's tomatoes, cucumbers, and peppers are grown in Mexico. Spielmann said, "It's impossible not to raise prices."

No one can easily escape this upheaval.

02 The Supply Chain Advantages of "Teslas" Are Being Destroyed

"After the U.S. tariff policy took effect, a pair of sneakers that used to cost $150 (approximately RMB 1,100) now sells for $230 (approximately RMB 1,688), equivalent to an $80 (approximately RMB 587) increase, or a 53% surge in price." A few days ago, Matt Priest, CEO of the Footwear Distributors and Retailers of America (FDRA), stated.

Specifically, if a pair of sneakers priced at $100 (approximately RMB 733) and produced overseas were manufactured domestically in the U.S., the price would rise to $300 or $400 (approximately RMB 2,201 or 2,935) per pair, all due to the U.S. tariff policy.

With the tariff war on the brink of erupting, a chain reaction has already begun.

In the U.S., there are two very typical companies that have reaped tangible benefits from globalization. One is Apple, and the other is Tesla.

For Tesla, benefiting from globalization in the past, it could find low-cost supply chains worldwide, including raw materials, manufacturing, and production. For example, Tesla's battery supply chain relies heavily on Chinese suppliers like CATL and BYD, while also reducing production costs through the Shanghai Gigafactory; Apple's component production is spread across the globe, with the core assembly of the iPhone relying on Chinese manufacturing.

Once tariffs increase, these readily available benefits and cost advantages will disappear. Jiedian Finance analysis shows that tariffs will have three levels of impact on American companies led by Tesla and Apple:

Surging supply chain costs and plummeting corporate net profits

For automakers, the core component is the battery. Currently, over 80% of Tesla's power battery supply chain depends on Chinese companies. Once tariffs are raised, Tesla cannot find alternative suppliers in the short term, and production costs will soar.

Some might say that Tesla might ask Chinese battery suppliers to lower prices and share the tariff cost with them. But in fact, this is difficult to achieve. China's current electric vehicle market has fallen into a fierce price war, and battery suppliers have repeatedly lowered prices over the past year to compete for market share, leaving Tesla with little room to increase prices or negotiate.

Tesla's financial report shows that in 2022, Tesla's overall gross margin reached a peak of 29.1%, but its full-year gross margin has fallen to 18.2% in 2023. If the supply chain is disrupted, it may even fall below the breakeven point.

Short-term supply chain disruptions and production paralysis

In recent years, both Tesla and Apple have set up production lines in countries like India, Vietnam, and Mexico to enhance their anti-risk capabilities. However, in reality, these countries cannot replace China. After decades of deep cultivation, China has now formed a mature manufacturing system.

For example, as early as 2022, Tesla required its procurement department to reduce purchases of components made in mainland China and Taiwan and asked Chinese suppliers to travel to Mexico to build factories. However, to date, Mexico has not yet started construction, and Chinese companies that went to Mexico to build factories have only received a small number of orders from the Texas factory.

Image source: Tesla official website

High-end manufacturing relies on precise division of labor. With the sudden disruption of the supply chain, Tesla cannot find such a mature manufacturing system in the short term that simultaneously meets high productivity, high quality, high efficiency, and low cost.

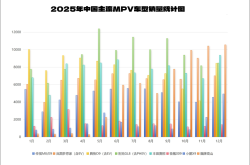

Consumers no longer buy, losing the Chinese market

Once Tesla raises prices, it will quickly lose the Chinese market. In the field of new energy vehicles, domestic new energy vehicle companies have flourished everywhere. With more choices and lower prices, consumers may not be willing to pay higher prices for Tesla. Tesla's market share in China will quickly be eroded by automakers represented by Huawei, Li Auto, XPeng, BYD, Xiaomi, etc.

Data shows that in 2024, Tesla's Shanghai Gigafactory rolled off its 3 millionth vehicle and exported its 1 millionth vehicle to overseas markets, with annual deliveries exceeding 916,000 vehicles, accounting for half of Tesla's global deliveries, and the Chinese market accounting for one-third of its global sales.

In the past, Tesla was the biggest beneficiary of Sino-U.S. economic cooperation. Now, it stands at the forefront of global trade rifts. And Tesla is merely a microcosm of this tariff war, with almost all industries caught in this upheaval.

03 Can Chinese enterprises withstand the pressure of tariffs?

"We are in foreign trade and are currently observing the situation," a foreign trade entrepreneur told Jiedian Finance. "In the short term, it will definitely affect our business, but fortunately, over the past few years, we have laid out markets and supply chains outside the U.S."

This tariff "gamble" led by the Trump administration not only threatens the survival logic of multinational companies like Apple but will also trigger a significant reorganization of global industrial and supply chains and a series of collateral effects.

How will Chinese enterprises respond?

The above-mentioned entrepreneur told Jiedian Finance, "In our view, the confidence and order volume of Chinese export enterprises may decline sharply in the short term, forcing some enterprises to reassess their export plans to the U.S. and instead try to explore other overseas markets or shift to the domestic market for layout."

As the famous British supply chain management expert Martin Christopher said, "Competition in the 21st century is no longer between enterprises but between supply chains."

The supply chain is the key.

Image source: Anker Innovation official website

Taking Anker Innovation as an example, this consumer brand that started in China but achieved great success in overseas markets has recently established a cross-departmental project team to continuously follow up on policy and market trends, and collaborate with front and back ends to formulate countermeasures. Jiedian Finance understands that in addition to its existing supply chain strategy, Anker Innovation is continuously advancing new supply chain strategies and establishing or expanding production and supply chain facilities in other countries.

Currently, Anker Innovation's business spans 146 regions and countries. In recent years, Anker Innovation has vigorously expanded non-U.S. markets such as Europe, Southeast Asia, Australia, and Latin America. With the expansion of new markets, the proportion of North American revenue has decreased year by year. By exploring incremental emerging markets, Anker Innovation aims to diversify regional policy risks.

In the past few years, Chinese enterprises going abroad have established supply chains in non-U.S. regions to reduce costs and expand more consumer markets.

After the tariff incident, Apple's supply chain enterprises have received much attention.

As an Apple supply chain enterprise, Lens Technology stated that after a comprehensive assessment, it is expected that changes in tariff policies will have a very limited impact on overall operations. The company said, "As of now, Lens Technology has 9 R&D and production bases globally, including production bases in Vietnam, Thailand, and Mexico, as well as multiple international offices. Tariffs are not the only consideration for overseas layout. This layout logic of being close to the market and spreading risks not only reduces logistics and labor costs but also deeply embeds the company into the customer's global supply chain system."

Financial reports show that overseas revenue accounted for 58.63% of Lens Technology's 2024 revenue, with most exports completed through domestic free trade zones to avoid tariff fluctuation risks.

Regarding component supply for overseas assembly plants, Lens Technology stated, "Our transactions with overseas customers use FOB or charge customers for freight, delivering to the designated destination, with the importing customer bearing the tariff payment. This clearly defined responsibility scheme has been proven effective in supporting mass production of complete machines in India, Vietnam, and other places."

Another example is Luxshare Precision.

In recent years of trade frictions, Luxshare Precision has made many layouts, such as diversifying customer structures, global capacity layout, and independent innovation of core technologies, to reduce the impact of single market fluctuations and geopolitical uncertainties.

Jiedian Finance learned that Luxshare Precision has currently established production bases and R&D centers in countries and regions such as Vietnam, Indonesia, Malaysia, Thailand, the United States, Mexico, and Romania, serving customers nearby and enhancing product cost advantages.

Under high uncertainty, the layout of overseas market supply chains determines a company's ability to respond to crises.

04 Wealth rapidly shrinking, American billionaires head to Mar-a-Lago

Not only Musk but also after the "Liberation Day" announcement of "comprehensive tariffs", Wall Street ushered in its darkest period. Apple, Meta, Amazon, Google, and NVIDIA saw their share prices fall, with Musk bearing the brunt.

Some media even commented on Musk, "Even if you lick their boots, you still get cut."

Under this effect, tech billionaires suffered heavy losses. According to statistics, the world's 500 richest people lost more than $500 billion. Especially those who smiled at Trump's inauguration, such as Zuckerberg, Bezos, and Musk, saw their fortunes shrink rapidly. It's worth noting that they had donated huge sums to Trump's campaign to help him get elected.

According to the Bloomberg Billionaires Index, Musk's net worth shrank by over $30 billion in just two days, Thursday and Friday of last week. Losing $30 billion in two days would make even Musk "stressed out".

These Silicon Valley giants are not helpless. It is reported that they have headed to Trump's private resort, Mar-a-Lago, hoping to secure exemptions.

For Musk, the damage may be even greater.

Last Wednesday, Musk said that high tariffs would significantly increase costs at Tesla's factories in the U.S. Recently, he directly appealed to Trump to revoke the new tariff policy. Three days later, Musk again expressed his hope to establish a U.S.-EU free trade zone and sharply criticized Peter Navarro, the White House trade advisor and one of the designers of the current U.S. tariff policy. All these indicate that he hopes to keep his distance from Trump on trade issues.

From cheering to keeping a distance, Musk has "had enough".

There are no winners in a trade war.

Facing the wave of price increases, American Apple fans' mindset has shifted from anticipation to "wallet defense". The latest statistics show that U.S. iPhone search volume surged 22% in a week, with "iPhone price increase" becoming a trending topic on Google Trends. Consumers have smelled the wind of price increases, and panic has quickly spread.

In response to panic buying, the supply chain has rushed to the rescue. From March 27 to 29, Apple dispatched three Boeing 747 cargo planes from Shanghai Pudong Airport, fully loaded with iPhones bound for Los Angeles, with a daily shipment volume exceeding 200,000 units. Data surveys show that if iPhone prices increase by more than 30%, 63% of American users consider abandoning Apple and switching to Android camp, such as Samsung Galaxy S25.

Both business owners and consumers are waiting for room for maneuver. The morning fog in Washington has not yet dissipated, and Trump's Mar-a-Lago is already shrouded in anxiety.

*The featured image is generated by AI