Minimize Failure Costs with High-Precision CT Inspection of Power Modules for New Energy Vehicles

![]() 08/08 2025

08/08 2025

![]() 590

590

Electric vehicle power systems distinguish themselves from traditional fuel vehicles through their electrification. Power electronics in these vehicles play a crucial role, converting the DC power stored in batteries into the various forms of electrical energy required for circulation within the vehicle. The cornerstone of these conversions and controls lies in power devices such as IGBTs and PCBAs in new energy vehicles.

▲ Enhancing Quality Control of Power Electronics Throughout the Entire Production Cycle

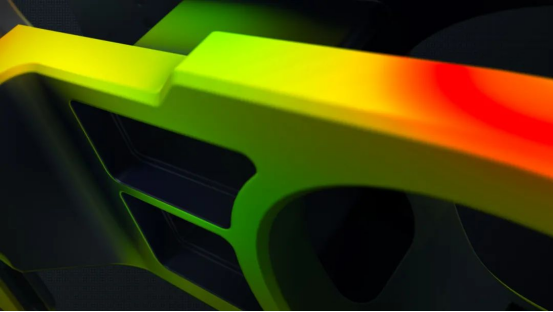

As vehicle electrification advances and automotive power electronics components become more complex and highly integrated, the volume of automotive electronics decreases while their output power increases, making product reliability paramount. In the trend of multi-in-one electric drive systems, power modules face increasingly stringent heat dissipation requirements in compact designs. Many automakers are looking to upgrade their heat dissipation technology to enhance the power density of electric drive systems in new energy vehicles. The welding process quality of power modules directly impacts their heat dissipation and current transmission performance. The welding processes in highly integrated modules are precise, complex, and highly susceptible to production environment influences, necessitating rigorous inspection to ensure part delivery quality.

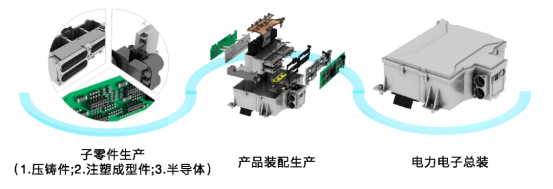

Electric vehicle power electronics assembly follows a linear production process, with most components supplied by vendors and assembled sequentially. Incoming inspection verifies part delivery quality before assembly, but new issues may arise during the assembly process. Therefore, it is essential to integrate inspection processes at each key work step to ensure production stability.

▲ Production Process of Power Electronics for Electric Vehicles

Non-Destructive Testing of Power Devices

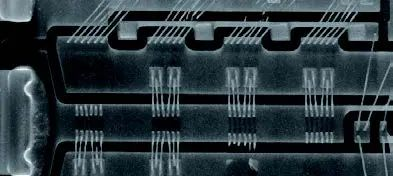

Research and Development – PCB Internal Wiring

- High-resolution and high-magnification CT of the entire PCBA

- Ideal imaging quality enhances PCBA's internal trace detection capabilities

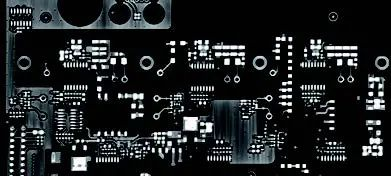

Research and Development – Welding Quality

- Ideal imaging contrast improves welding quality inspection results

Research and Development – Power Module Failure Analysis

- Provides a clear overview of failures to assist in identifying root causes

- Detects various failure defects, including welding defects, connection failures, and internal cracks

Quality Lab – Power Module Internal Structure Inspection

- One-stop CT solution for comprehensive analysis of the entire unit

- Statistical data and quantifiable results aid in formulating manufacturing standards and process validation

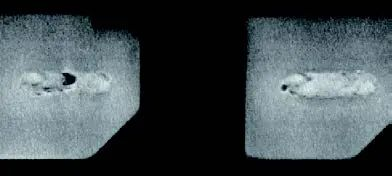

Quality Lab – Laser Welding Process Control

- Non-destructive inspection of the welding process during production

- Clear scan results effectively determine the state of the molten pool

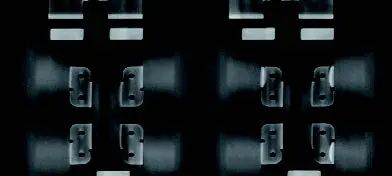

Quality Lab – Crimping Process Quality Control

- High-precision inspection results for measuring crimping quality

- Random inspections to ensure internal crimping quality between power modules and PCBAs

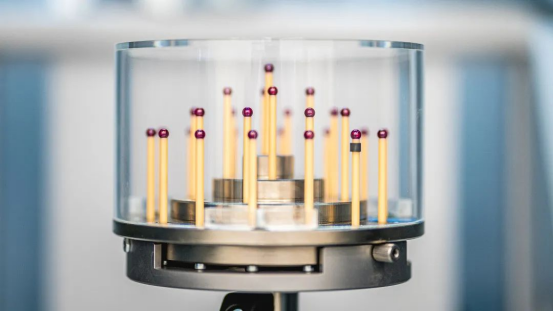

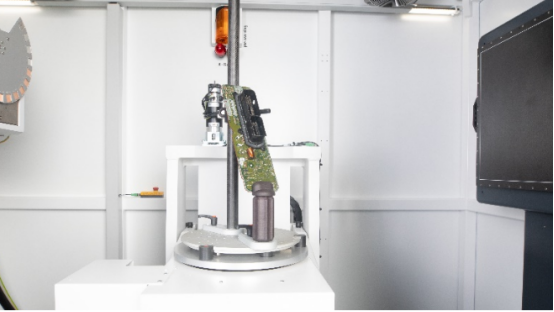

Zeiss Industrial CT technology, tailored for power electronics in new energy vehicles, replaces traditional dimensional measurement with high-precision CT inspection. This enables non-destructive testing of power device and connector interiors, helping manufacturers reduce costs associated with destructive testing. Furthermore, industrial CT equipment boasts sufficient internal space to complete the measurement of all internal PCBAs in a single scan and can perform high-magnification precision inspections of small internal components. Equipped with the scatterControl module, the equipment effectively reduces scattering artifacts and enhances the imaging quality of component interiors. The one-stop solution provided by the ZEISS INSPECT software can automatically inspect multiple components, assess their defects, structures, and assemblies, and analyze geometric dimensions.

▲ Reliable CT System: ZEISS METROTOM 800

▲ High Precision at Any Position

▲ Effectively Reduces Scattering Artifacts

▲ One-Stop Solution Provided by ZEISS INSPECT Software

▲ Strong Load Capacity and Large Internal Space

Get the Brochure

Click the image to download the solution brochure for more details