Benchmarking Benz: What Are We Really Measuring?

![]() 08/12 2025

08/12 2025

![]() 691

691

Looks ≠ Drives

Author | Wang Lei

Editor | Qin Zhangyong

In China's luxury car market, Benz has virtually become the gold standard.

At numerous new car launches, Benz is frequently used as a benchmark for comparisons, leading to conclusions drawn through various parameters and tests:

In terms of XX, Benz falls short of us.

Regardless of whether the testing methods are official, comparing a single data point alone reveals the deceptiveness of such comparisons.

Moreover, from a strategic standpoint, when a product is benchmarked against another, it inherently acknowledges the benchmark's superiority.

As the saying goes, "Buy the car that everyone benchmarks against, and you can't go wrong."

Recently, we attended the Benz Tech Day. With each meticulously dissected seat and intricate detail, I gained insight into a fundamental principle: the true value of luxury cars lies beyond mere parameters and presentations.

01

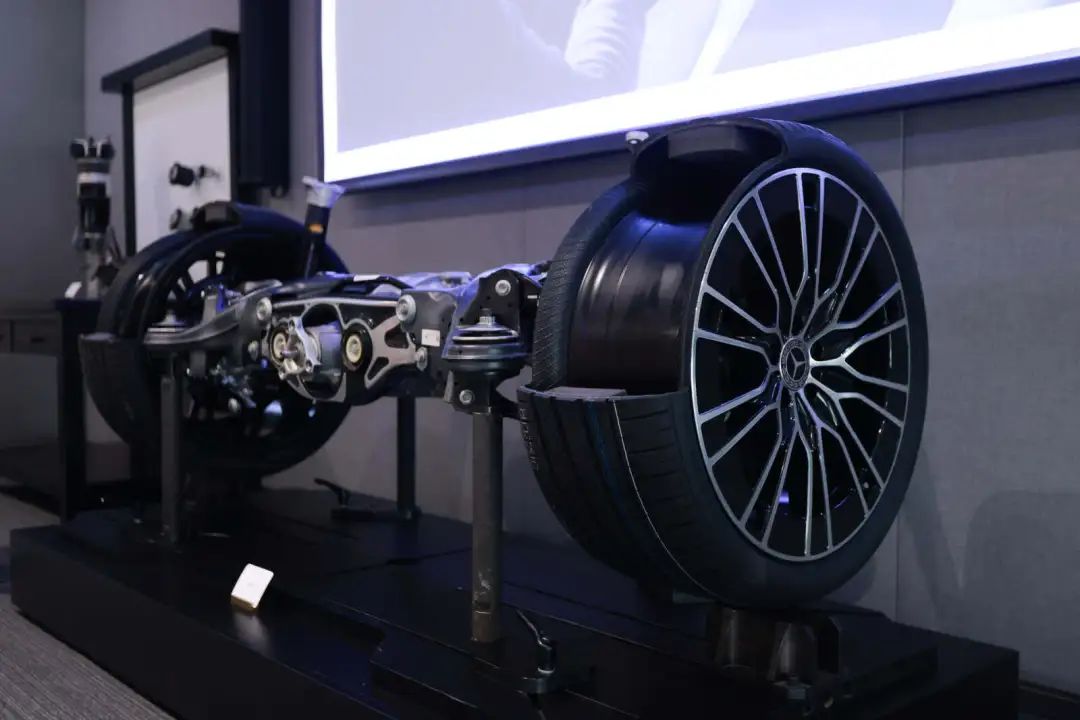

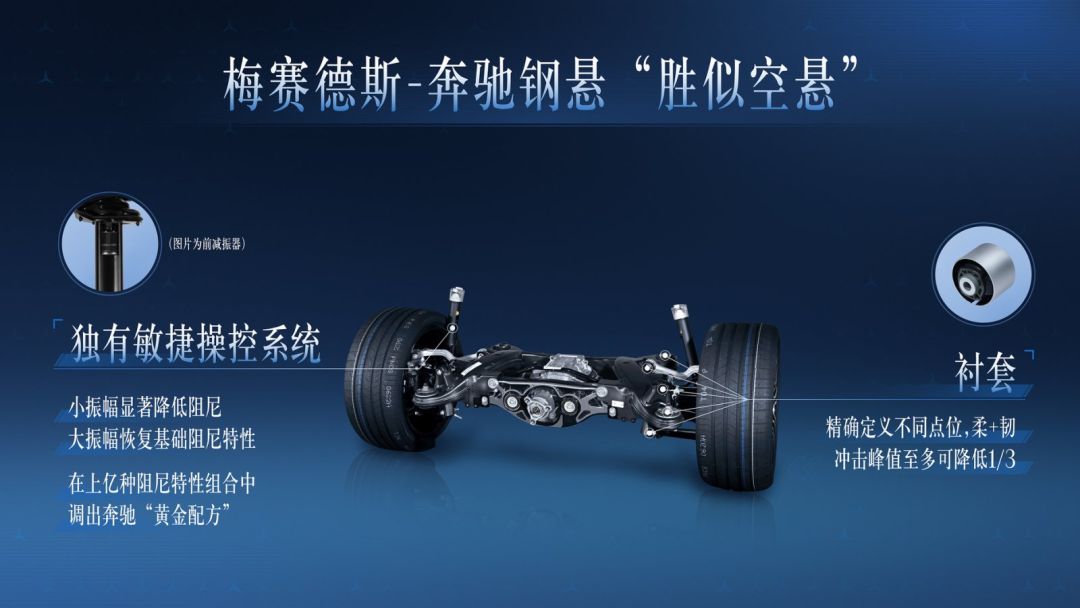

What Constitutes a Superior Chassis?

"Drive a BMW, ride a Benz."

This saying is undoubtedly familiar. In today's era of new cars, where clever wordplay is rampant, the public's understanding of comfort is often defined by an array of data and parameters.

However, comfort has never been a mystique created by stacking parameters. When you experience the sensation of "riding a Benz," you realize that Benz is still Benz, and it's not as simple as a so-called brand premium.

For instance, the seemingly straightforward criteria of being easy to drive and sit in involve complex and meticulous engineering technology behind the scenes.

According to Benz, the chassis is not merely science; it's a systematic and intricate engineering project, an art of balancing various dimensions and perceptions. Internally, the chassis system involves the interplay of components like tires, suspension, shock absorbers, and bushings, while externally, it must adapt to various road conditions.

These factors are interconnected, and Benz breaks down chassis performance into over 1000 component indicators, ultimately quantifying them into more than 130 objective KPIs.

These data are measured by 40 sensors, covering over 100 directions. After post-processing, these data are summarized into a complex logic encompassing five major dimensions: ride comfort, safety, control, sportiness, and precision.

Benz's chassis development process begins with CAD design, progresses through digital twin simulation, digital prototype testing, prototype vehicle testing, and digital twin validation, ultimately culminating in mass production vehicles. It undergoes durability verification over two winters and two summers, covering 5 million kilometers globally, including 1.1 million kilometers in China.

Every new vehicle must achieve a balance in these six steps and five dimensions to qualify for mass production. It is through this complex and lengthy testing process that Benz presents an image of meticulous craftsmanship.

This is precisely the value Benz places on car manufacturing. A superior chassis is not just a collection of individual configurations. Moreover, Benz's long-wheelbase models are not mere extensions of the standard wheelbase. Within the same model series, the long-wheelbase and standard wheelbase are verified simultaneously to ensure the reliability of the actual vehicle's chassis.

Beyond objective parameters, due to the diverse needs of each individual, Benz also employs a set of subjective standards that are "unorthodox"—tuning that is purely tested by humans.

In Benz's view, a chassis that looks good may not drive well. Objective evaluation is only a "single-point evaluation" of the chassis's performance, while subjective evaluation is a holistic judgment of the chassis as a whole. You won't know if the chassis is good until you drive it.

Benz boasts an exceptionally capable subjective testing team that does not rely on objective testing equipment but solely on human perception to judge the chassis, also known as the "Popometer".

Their work may seem straightforward, but it is crucial to vehicle development. For example, during one test, a test expert from the China R&D Technology Center noticed a wheel imbalance issue after just a 5-minute test drive, even pinpointing the imbalanced wheel, and subsequent inspections confirmed his judgment.

This gives Benz the confidence to claim that "its steel suspension is superior to an air suspension" and that its unique "Agility Control" system can sift through hundreds of millions of damping combinations to find the most Benz-like setup.

Since different users have varying definitions of a "good chassis," this necessitates finely tuned suspension styles and configurations to meet diverse travel needs and adapt to customers' different driving habits, truly satisfying users' needs in a vast majority of real-life travel scenarios and over long-term use.

This has led to the development of over 10 suspension styles, including comfort, sport, and off-road suspensions, based on the positioning of different models and the common scenarios of their corresponding customers.

02

A Seat Crafted Over 1460 Days

Tuning to the "Benz" standard involves more than just chassis development; seats are the crucial link that supports the chassis's texture and enhances the user experience.

How many days do you think it takes for an automaker to craft a seat?

Benz's answer is 1460 days.

It's hard to fathom that it takes such a long cycle to craft a car seat. Nowadays, new energy vehicles are being "rushed" to market at an average pace of two years from development to launch. At Benz, the seat development cycle isn't even halfway through.

At this Benz Tech Day, one of the most engaging segments was when engineers let us pick up scalpels and dissect a seat directly, revealing its internal structure so that we could clearly see the function and details of each layer.

Of course, if you're an R&D personnel from a certain automaker and purchase a Benz car, you can use a magnifying glass to imitate and copy it.

In this way, you can learn half of Benz's prowess in a short period, but to master the other half, you must refine it step by step.

According to Benz's standards, the seat is a systematic project that integrates over 6000 standard controls, far more complex than a sofa. Taking the dissected E-Class seat as an example, it has over 1000 precision parts, uses over 400 sets of tooling to cover materials, functions, comfort, and safety, and undergoes over 2000 special tests and simulations, as well as over 3000 configuration combinations, including different stitching, colors, and functions.

A few details highlight this. For example, in the E-Class model, the heating coverage of the seat reaches 0.84 square meters, encompassing not only the backrest and cushion but also the side wings and headrest. The S-Class even provides heating functions in the center console armrest, door armrest, etc., with the heating wire length at the driver's position reaching up to 39 meters.

You won't feel burning even after sitting for a long time because engineers have eliminated "hot spots" through thermal mapping technology to maintain even temperature control. During use, the system monitors and controls the energy output to keep the seat surface at the optimal body temperature with dynamic temperature control.

This is just the process for a single version of the model. A truly exceptional seat rejects generality. Benz develops exclusive skeleton platforms for different models, ensuring that each seat perfectly matches the model's space and functional requirements. Within the entire Benz family, there are thousands of such unique seat types.

Complementing the high-standard seat skeleton are Benz's stringent safety standards for seats. Benz conducts over 200 seat safety tests and over 100 additional tests on key components. For this purpose, Benz has prepared over 120 test dummies, covering different genders, heights, and body types.

These 120 "dummy celebrities" come in 21 types, including seat test-specific dummies in 95th percentile male, 50th percentile male, and 5th percentile female specifications, covering different body types ranging from 148 cm to 188 cm and from 56 kg to 108 kg, to simulate collision results for passengers of diverse body types.

Moreover, in terms of durability standards, Benz's seats undergo a total of about 40,000 "getting in and out" tests, including 24,000 mechanical simulation tests and 15,000 real-person tests. If calculated at 6 entries and exits per day, this testing standard equates to continuously using the seat for over 18 years.

Benz's story in China began in 2005, and this year marks the 20th anniversary of Benz's production in China. With a 139-year history of car manufacturing, Benz has always regarded China as its most important market outside its home country.

Today, Beijing Benz has become one of the largest and most advanced manufacturing bases in Mercedes-Benz's global production network. The China R&D Technology Center has also evolved into the largest and most powerful R&D network outside Germany for Mercedes-Benz.

In the automotive industry, there's a consensus that car manufacturing is a long-term endeavor with no shortcuts. If anyone is most qualified to say this, it's probably Benz.

Similarly, Benz is also keeping pace with the times. Last year, Benz announced an investment of over 14 billion yuan to launch the most aggressive product and technology offensive in China's market to date.

Whether it's technology or luxury, the logic of defining a "good car" remains unchanged. Benz has consistently proven this with its actions.