Global Sales Leader Toyota: Is It Also Facing Challenges?

![]() 10/10 2025

10/10 2025

![]() 627

627

Toyota has released a global performance report, showing an overall uptick in sales volume. However, it finds itself trapped in the dilemma of 'rising revenues without corresponding profit growth.' How will the world's top-selling automaker navigate through the tariff crisis?

On July 30, Toyota Motor Corporation unveiled its global sales performance report for June and the first half of 2025. The data indicates an overall improvement in the company's performance during the first half of the year. From January to June, cumulative sales reached 5.5449 million units (including Daihatsu Motor and Hino Motors), marking a year-on-year increase of 7.4%. This achievement not only sets a new record for Toyota's sales volume in the first half of the year over the past three years but also secures Toyota's position as the global leader in automaker sales volume for the sixth consecutive year in the first half of the year.

Toyota attributes this growth to robust demand in key markets such as the United States, Japan, and China. However, beneath the impressive sales figures lies a hidden concern—the global top-selling automotive company is now grappling with the dilemma of 'rising revenues without corresponding profit growth.'

Behind the 'Rising Revenues Without Corresponding Profit Growth'

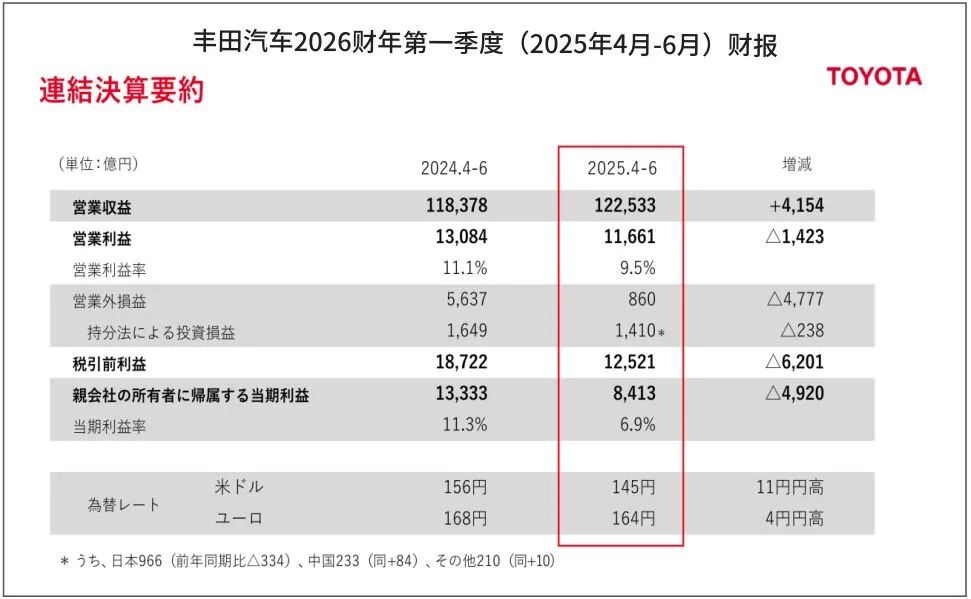

The financial report for the first quarter of the 2026 fiscal year (April-June 2025), released by Toyota on August 7, highlights this contrast. The data reveals that Toyota's revenue for the quarter reached JPY 12.25 trillion (approximately RMB 596.208 billion), a year-on-year increase of 3.5%. However, its operating profit decreased by 11% year-on-year to JPY 1.17 trillion (approximately RMB 59.644 billion). Meanwhile, Toyota's net profit also saw a significant decline of 37%, falling to JPY 841.4 billion (approximately RMB 41 billion). The company also announced a downward revision of its full-year operating profit forecast from JPY 3.8 trillion to JPY 3.2 trillion (approximately RMB 155.68 billion), a decrease of 16%. The net profit forecast was lowered by approximately 44%.

This dilemma is not unique to Toyota but is a common experience among all Japanese automakers. Recent financial reports indicate that Japanese automakers suffered significant setbacks in the first quarter of the 2026 fiscal year (April-June 2025), with profits declining to varying degrees. Among them, Honda's net profit for the first quarter was JPY 196.6 billion (approximately RMB 9.54 billion), a year-on-year decline of 50.2%. Nissan shifted from profit to loss, with a net loss of JPY 79.1 billion (approximately RMB 3.84 billion) for the first quarter, and its operating profit margin dropped to -2.9%.

Industry insiders point out that the US tariff policy is the primary reason for the profit decline of Japanese automakers. According to data from the Japan Automobile Manufacturers Association, Japan exported approximately 1.37 million vehicles to the United States in 2024, accounting for over 30% of its total exports. Meanwhile, data from research company MarkLines shows that Japanese vehicle sales in the US were also substantial. In 2024, US vehicle sales were approximately 16 million units, with Japanese automakers such as Toyota, Honda, and Nissan accounting for nearly 40% of the market share. Nearly half of the models sold by these Japanese brands in the US rely on imports.

Regarding complete vehicles, the United States once imposed a tariff as high as 25% on passenger vehicles imported from Japan (with significant increases in tariffs on some components as well). This means that even if automakers like Toyota choose to increase production facilities in the United States, if they rely too heavily on importing components from Japan or other regions, their cost burdens may still increase significantly. Therefore, for Japanese automakers, high tariffs pose tremendous pressure. Although Japan recently reached a relevant agreement with the United States, agreeing to lower the tariff to 15%, the specific implementation timeline has not been determined. According to Toyota's estimates, even with a 15% tariff, the company's annual losses due to this would still reach JPY 1.4 trillion (approximately RMB 67.82 billion).

It is worth mentioning that some Japanese automakers have already adjusted their global production layouts to cope with the current challenging new trade environment. Among them, Nissan suspended the production of Infiniti models at its factory in Coahuila, Mexico, for supply to the US market, while Honda was forced to transfer the production line of the Civic hybrid model from Japan to the United States.

Toyota has also made strategic adjustments, deciding to further deepen its presence in the US market and increase the production proportion of localized models. It is reported that since the 1950s, Toyota has established 11 complete vehicle and component factories in the United States, with localized models accounting for nearly 50% of its production. This year, Toyota also announced an additional investment plan for its factories in the United States, totaling approximately USD 88 million (approximately RMB 633 million), aimed at strengthening production capacity in the US and enhancing supply chain resilience. Meanwhile, Toyota will also increase its investment by USD 2.1 billion in its battery factory under construction in North Carolina. The factory is expected to start production in 2025, and its produced lithium batteries will mainly supply Toyota's electric vehicle factory in the United States.

Strengthening Domestic Operations Before Expanding Abroad

However, industry insiders point out that as Toyota's largest single market and core profit source for a long time, the increase in US domestic production will inevitably lead to a decline in demand for Japanese domestic supply. If new breakthroughs are not found in a timely manner, Toyota's existing market foundation may face the risk of being weakened. In this context, China, as Toyota's second-largest global market, has undoubtedly become a key consideration in its strategic planning.

In China, Toyota has established a complete localized supply system, covering multiple production bases, research and development centers, and in-depth cooperation with local enterprises. Data shows that in the first half of 2025, Toyota's sales volume in China reached 837,700 units, a year-on-year increase of 6.8%, performing particularly prominently among joint venture automakers.

It is worth noting that in April this year, Toyota's Lexus brand (LEXUS) officially settled its first overseas research, development, and manufacturing base for pure electric vehicles and power batteries in Jinshan District, Shanghai. The project is expected to be completed in August 2026, with the first mass-produced vehicle rolling off the line in 2027. This move also means that the production capacity of related models will gradually shift to China.

Admittedly, for Chinese consumers, localized production is expected to reduce vehicle purchase costs, undoubtedly good news. However, for the Japanese supply chain, the relocation of high-end production capacity means the risk of order loss. At Toyota's operating performance press conference in May 2025, Toyota Motor Corporation President Koji Sato explicitly pointed out this challenge. He stated that Toyota's top priority is to diversify its exports and emphasized in particular, 'If the increase in US domestic production is not accompanied by growth in exports to other regions, then Japan's domestic production system will have to be reconsidered.' This foreshadows that if the tariff issue cannot be properly resolved, Japan's domestic automotive industry chain will also suffer.

It is worth noting that the automotive manufacturing industry is a pillar industry in Japan, and as the leader of this industry, Toyota itself is of great significance in ensuring employment and social stability. For this reason, Toyota has set a benchmark goal of producing 3 million vehicles annually in Japan and has adhered to it for several consecutive years. Its core purpose is to safeguard domestic manufacturing capabilities, employment opportunities, and the stability of the supplier system while creating higher GDP contributions for Japan through exports.

For reference, in the 2024 fiscal year, Toyota produced 3.23 million vehicles in Japan, with nearly 60% exported overseas. The United States, as a key export market, accounts for 28% of Toyota's total exports. Public data shows that Japan's automotive supply chain covers more than 68,000 enterprises, with many small and medium-sized enterprises relying entirely on Toyota's domestic orders for survival. Even for component giants like Aisin and Denso, nearly half of their annual revenue comes from Toyota.

There have been precedents for such crises—the decline of Detroit, the 'Rust Belt' of the United States, serves as a stark example of industrial relocation. Historically, vehicles produced in Detroit once occupied a significant share of the global market, earning it the title of the 'Motor City.' However, as US labor costs rose, American giants like General Motors were forced to gradually relocate their production capacity to overseas regions with lower labor costs, such as Mexico, year after year. This directly led to a significant decline in Detroit's population, eventually leading to the city's decline and its declaration of municipal bankruptcy in 2013.

Expanding Overseas While Safeguarding Domestic Foundations

However, in the face of severe circumstances, Toyota has indeed taken measures to maintain its domestic supply chain system. To sustain its goal of producing 3 million vehicles annually in Japan, Toyota plans to reorganize its production base layout in Japan over the next decade: for example, reducing annual vehicle production in central Japan by 20% to approximately 1.8 million units, while increasing annual production in northeastern and southern Japan by 50% to approximately 600,000 units each. This move aims to address labor shortages, ensure a stable number of young workers, mitigate the potential risks of the Nankai Trough earthquake, and increase production capacity for electric vehicles and other next-generation vehicles.

In terms of overseas market expansion, Toyota is also continuously making efforts. Facing the trend of escalating global trade barriers and supply chain reorganization, Toyota announced that it will launch approximately 15 self-developed electric vehicle models by 2027 and expand its production footprint to five countries: Japan, China, the United States, Thailand, and Argentina. Toyota expects that its global annual production volume of electric vehicles will reach approximately 1 million units by 2027, a sevenfold increase from 2024. Currently, Toyota's new Hilux pickup truck has been launched in emerging markets such as Australia; the new bZ4X is undergoing testing in Thailand and is expected to be launched in late 2025 or early 2026 to enhance Toyota's competitiveness in the Southeast Asian electric vehicle market.

In this process, Japanese domestic factories will shoulder the core production responsibilities. The Takaoka Factory in Aichi Prefecture plans to produce the C-HR Plus model from September 2025, with an expected monthly production capacity of 10,000 units; the Tahara Factory plans to start production of the next-generation Lexus all-electric flagship model from August 2027. In addition, Subaru's Yajima Factory in Gunma Prefecture will also start contract production of an SUV jointly developed by Toyota and Subaru from February 2026, with an expected monthly production capacity of 15,000 to 20,000 units, and the products will be sold in the Japanese, North American, and European markets.

Meanwhile, on August 7, Toyota announced that it would purchase land in Toyota City, Aichi Prefecture, Japan, to build a new complete vehicle manufacturing factory. The new factory is expected to start production in the early 2030s, with the specific production model to be determined later. The factory will aim to create a 'factory of the future' that integrates cutting-edge technologies and position domestic factories as 'mother factories,' retaining advanced production technologies and manufacturing processes as the core competitiveness of Japanese manufacturing in Japan to prevent the rapid outflow of key technologies.

'Despite the challenging external environment, we will continue to make comprehensive investments,' Toyota emphasized in a statement not long ago: the company is alleviating negative impacts by increasing sales volume, cutting costs, and expanding value chain profits. According to reports from multiple Japanese media outlets, Toyota has informed suppliers that it will raise its global production volume target for 2025 to approximately 10 million units, a slight increase from the initially planned 9.9 million units; it also plans to raise its production volume forecasts for 2026 and 2027 to 10.2 million units and 10.5 million units, respectively, an increase of approximately 200,000 units each from the initially planned figures.

Currently, the global automotive industry is undergoing unprecedented changes. Toyota's dilemma of 'rising revenues without corresponding profit growth' is a microcosm of the transformation pains faced by traditional automotive giants. From the second quarter and first-half financial reports recently released by major multinational automakers, it can be seen that the net profits of mainstream automakers such as Volkswagen Group, Mercedes-Benz, BMW, Hyundai Motor, Kia, and General Motors have all declined to varying degrees. Indeed, every automaker has its own difficulties.

For Toyota, on the one hand, it faces passive production capacity relocation under the heavy pressure of tariffs in the North American market; on the other hand, it bears the tremendous responsibility for the survival of the domestic industry chain. If US tariffs continue to increase or policies fluctuate (such as tariff rate adjustments or tightening of exemption clauses), it will further compress the profit margins of automakers and force the reorganization of their domestic industry chains.

Against this backdrop, Toyota has embarked on an exploration of a potential strategic path for leading multinational automotive manufacturers: reinforcing their domestic foundations while simultaneously expanding their global reach. Should this endeavor prove successful, it could potentially pioneer a new paradigm of "technological localization coupled with global production capacity" amidst the looming threat of tariff crises. Conversely, if this strategy were to falter, the ensuing ripple effects could be just as devastating, if not more so, than a large-scale economic earthquake.

Note: This article made its debut in the "Hot Topic Tracking" column of the September 2025 edition of Auto Review magazine. Stay tuned for more insights.

Image: Sourced from the Internet

Article: Auto Review

Layout: Auto Review