Payment Terms Reduced to 60 Days: Major Automakers Commit, Chinese Automakers Reject 'Extended Payment Terms'!

![]() 06/12 2025

06/12 2025

![]() 674

674

Recently, several prominent automakers, including FAW Group, Dongfeng Motor Corporation, Changan Automobile, GAC Group, Thalys, and Geely Automobile, have announced their commitment to strictly adhering to the revised "Regulations on Guaranteeing Payment for Small and Medium-sized Enterprises" issued by the State Council. These automakers will now uniformly reduce their payment terms for suppliers to within 60 days, taking tangible steps to enhance capital circulation efficiency within the industrial chain and bolster the growth of small and medium-sized enterprises.

This move positively responds to the official implementation of the revised regulations, which came into effect on June 1st.

With central enterprises, state-owned enterprises, and other leading firms embracing the new payment term requirements, upstream parts suppliers can finally breathe a sigh of relief, marking an initial success in the fight against industry-wide delays. Central enterprises have made their stance clear, and it remains to be seen who will fail to follow suit.

Central enterprises, state-owned enterprises, and leading private enterprises have responded positively.

Here’s a breakdown of their actions: FAW Group vows to ensure the implementation of the "60-day payment" requirement through improved mechanisms, optimized processes, and technological empowerment, guaranteeing timely payments. Dongfeng Motor has announced the unification of payment terms to within 60 days, aiming to boost capital circulation efficiency both upstream and downstream and support the harmonious development of the industrial chain. Changan Automobile, along with its subsidiaries Changan Qiyuan, Changan Kaicheng, Shenlan Automobile, and Avita, will also adhere to a 60-day payment term for suppliers. GAC Group reaffirms its commitment to maintaining supplier payment terms of no more than 60 days, ensuring efficient capital turnover in the supply chain. Thalys has issued an initiative to jointly promote industry quality development, stating that it always pays suppliers in accordance with contractual terms, with a standard payment term of 60 days, fostering a win-win situation for both OEMs and suppliers. Geely Automobile Group promises a unified payment term of within 60 days to safeguard industrial chain stability.

On June 1st, the State Council issued the revised "Regulations on Guaranteeing Payment for Small and Medium-sized Enterprises" for implementation. Article 9 of Chapter 2 stipulates that government agencies and public institutions procuring goods, projects, and services from small and medium-sized enterprises must make payments within 30 days from the date of delivery; if the contract specifies otherwise, it must adhere to the contract, but the payment period cannot exceed 60 days.

If both parties agree on an interest rate for overdue payments, the agreed rate must not be lower than the one-year loan prime rate at the time of contract conclusion; in the absence of an agreement, overdue interest will be charged at a daily rate of 0.05%.

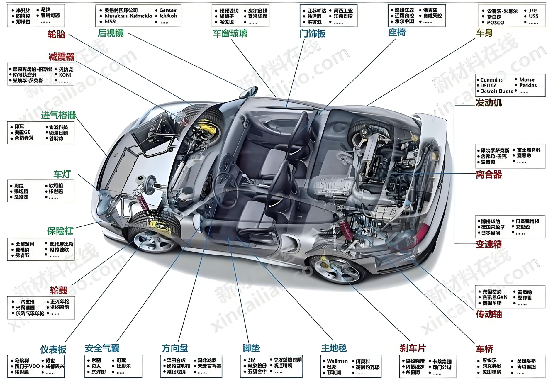

Objectively speaking, China's new energy vehicle industry has been able to surge ahead and witness continuous growth in production and sales due to product and technological breakthroughs by many automakers, as well as the support of a well-established supply chain. As the saying goes, even a clever housewife cannot cook without rice – this is indeed the truth. Car production is not merely the assembly completed in the workshop but the result of concerted efforts across multiple supply chains, ensuring efficient and accurate completion of every step from design to delivery.

Therefore, the supply chain and OEMs should maintain a collaborative relationship. However, the current reality is that OEMs tightly control suppliers. This is primarily because under the new business model, the automotive industry is undergoing tremendous changes, not only in product form, evolving from traditional fuel vehicles to electrification and intelligence, but also in the survival state of the supply chain. Very few suppliers have grown into giants that OEMs cannot match, such as Huawei and CATL, while most suppliers have lost their original bargaining power.

Especially amid the ongoing price war, OEMs themselves are struggling, and non-leading suppliers are facing even greater hardships. This jeopardizes the stability of the entire industry's supply chain and, if left unchecked, could damage the healthy development of China's automotive industry and even undermine the advantages gained by new energy vehicles in recent years.

Extended Payment Terms Squeeze Suppliers' Survival Space

China's automotive price war has been raging for over two years with no end in sight, and the pressure to reduce costs has been transmitted from the market to automakers and then upstream to the supply chain.

According to statistics, the average number of days for accounts payable in China's automotive industry currently stands at 182 days, far exceeding the 90-day benchmark of international automakers. Media reports indicate that six out of 16 listed Chinese automakers have a turnover period exceeding 180 days. Haima Automobile has the longest turnover period of 298 days, followed by BAIC BJEV at 252 days. Isn't that astonishing?

The market attaches great importance to the number of payment term days because the longer the payment term, the longer the enterprise occupies funds (interest-free debt) and the slower the payment speed. Extended payment terms lead to a surge in accounts receivable for small and medium-sized suppliers, forcing them to obtain high-cost discount financing, which compresses their profit margins. Suppliers may reduce production, lay off employees, or even go bankrupt due to capital chain disruptions, as evidenced by a case where a new automaker's 300-day payment term led to the bankruptcy of 32 suppliers, causing a loss of 2 billion yuan due to supply disruptions.

In November 2024, Tesla's Global Vice President, Tao Lin, stated that Tesla's payment cycle to suppliers was around 90 days, shorter than in 2023. In January 2025, Lu Xiao, General Manager of SAIC-GM, emphasized at the annual media communication meeting that since the company's establishment 28 years ago, even during the most difficult times, the average payment cycle to suppliers has been 40-60 days, and it has never defaulted on payments to suppliers.

When compared to international automotive giants, the payment turnover days for Mercedes-Benz, BMW Group, and Volkswagen from January to September 2024 were 47 days, 42 days, and 44 days, respectively. The payment turnover days for Nissan, Toyota, and Honda were 74 days, 53 days, and 32 days, respectively. Ford Motor and General Motors had payment turnover days of 62 days and 70 days, respectively.

The significantly shorter payment term days of international giants are influenced by the commercial practices of their home countries. Taking Germany as an example, it has specific legislation addressing delayed payments in commercial transactions. Once the standard payment deadline is exceeded, creditors are entitled to obtain default interest at a rate 9 percentage points higher than the base rate.

It's reasonable to believe that the timely payment cycles to suppliers have played a crucial role in the decades-long success of international giants.

This time, Chinese automakers have collectively pledged to reduce payment terms to 60 days, which means suppliers' capital recovery cycle will be shortened by nearly two-thirds. This is conducive to fostering a more efficient supply chain development in China's automotive industry.

In fact, OEMs and the supply chain are currently undergoing a critical period of resource reorganization, necessitating the establishment of a more robust and sustainable supply chain relationship rather than a simple zero-sum game.

People's Car Review

The market economy is complex and diverse, evolving over the long term. This is particularly true in the automotive market. Currently, central enterprises, state-owned enterprises, and leading automakers have all expressed their intention to adhere to the new payment cycle, marking a promising start.

Certainly, the relationship between OEMs and suppliers is complementary, and the interests of both parties need to maintain a long-term balance.