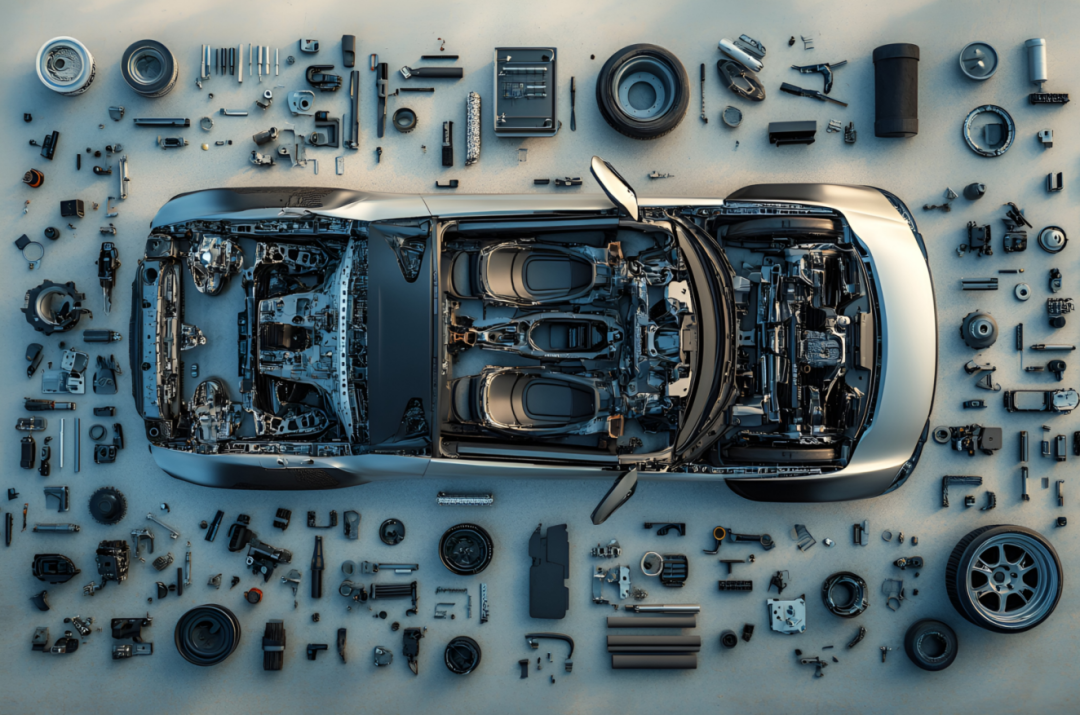

17 Auto Manufacturers Commit to '60-Day Payment,' Alleviating Supplier Pressures?

![]() 06/12 2025

06/12 2025

![]() 584

584

From June 10 to 11, 17 auto manufacturers, including GAC, FAW, Dongfeng, and BYD, jointly announced their commitment to reducing payment periods for suppliers to within 60 days. This concerted action positively responds to the 'Regulations on Guaranteeing Payment to Small and Medium-sized Enterprises,' which took effect on June 1, and serves as a ripple effect to regulatory measures against 'convoluted' competition in the automotive industry.

According to the 2024 annual reports and Wind data of 12 domestic listed auto manufacturers, the average payable turnover days stands at 171.6 days, significantly longer than the 40.5 days of German brands (BMW, Volkswagen, Mercedes-Benz), 54.8 days of Toyota, and 60.5 days of American brands (GM, Tesla, Ford). From 2021 to 2023, the average payable turnover days for domestic auto manufacturers increased from 151.5 days to 164.1 days, though four enterprises have shortened their turnover days to varying degrees, a trend that continued into 2024.

While it is common for auto manufacturers to regularly reduce procurement prices annually, the current situation differs in that the frequency and magnitude of these reductions are excessive, with arbitrary reasons and standards, exerting continuous pressure on the supply chain system and fostering a vicious cycle. As policy focus shifts to implementation, the industry reaches a consensus but also debates the boundaries of genuinely enacting this initiative, with challenges still persisting.

▍Payment Period Commitment vs. Reality

Collective statements under policy pressure cannot obscure the deep-seated structural contradictions within the industry. The direct impetus behind this commitment by auto manufacturers stems from the State Council's revision of the 'Regulations on Guaranteeing Payment to Small and Medium-sized Enterprises.' This regulation mandates large enterprises to make payments within 60 days and prohibits small and medium-sized enterprises from being forced to accept non-cash payment methods like commercial bills of exchange and electronic vouchers, nor can payment periods be disguisedly extended using such methods.

Simultaneously, the Ministry of Industry and Information Technology (MIIT) listed rectifying supply chain capital imbalance as a key task. The China Iron and Steel Association issued a document stating that some auto manufacturers use supply chain financial platforms to convert payments for raw materials like steel into deferred bills of exchange, forcing upstream enterprises to bear financing costs.

On June 12, the official government affairs new media account of the MIIT emphasized that the industrial chain and supply chain are the 'backbone and lifeblood' of the automotive industry, crucial for industrial transformation and upgrading. With intensifying competition in the new energy vehicle market, competitive pressure trickles down from automakers to the industrial chain, leading to extended supplier payment periods and capital turnover difficulties, detrimental to industrial technological innovation and healthy, sustainable development.

Even more alarming is the imbalance in debt structure. In 2024, the average proportion of accounts payable to liabilities for some domestic listed auto manufacturers reached as high as 46.22%, compared to 8.99% for Toyota during the same period. This indicates that nearly half of automakers' liabilities stem from the occupation of supplier funds, with suppliers needing to pay a 5%-8% discount fee to cash bills of exchange in advance.

Moreover, some suppliers told Auto Insight that the rules for calculating the payment period's starting point pose practical challenges. They questioned, 'Which node does the 60-day payment period refer to? Is it after the invoice is issued? Before the invoice, there are material acceptance, project summaries, settlement contract signing, and execution, with potential delays at any stage. Acceptance can be delayed, settlement contracts not signed, summary materials not reviewed, and settlement only after bargaining for a 10%-20% discount. Manipulation is rampant.' They pointed out that automakers often delay verifying and canceling receipt documents, extending the actual payment period beyond the agreed terms, and the 'consignment system' combined with centralized accounting rules can make the period from goods entering the factory to payment exceed 10 months.

Suppliers' concerns also stem from the price transfer mechanism. Some automakers leverage the acceptance of a 60-day payment period to demand price reductions of 10%-15% or transfer R&D and testing costs to suppliers. A financial professional noted significant differences between payment methods like telegraphic transfer, bank acceptance, and commercial acceptance.

▍The Battle to Defend the Industrial Chain's Survival

As discussions about the industrial chain intensified, during the last trading week of May, the share prices of 88 listed Chinese auto companies fell by an average of 2.41%, ending a three-week rally and erasing nearly RMB 660 billion in total market value, retreating to RMB 8.8 trillion. Public data shows that the net profit margin of auto parts suppliers in the automotive industry plummeted from 9% in 2015 to 3.8% in the first quarter of 2025. A supplier with monthly sales of RMB 10 million often has over RMB 100 million in occupied funds, effectively raising the industry's entry threshold tenfold.

A chassis supplier engineer bluntly stated, 'For every day the payment period is extended, a batch of enterprises loses competitiveness due to discount interest.' When suppliers focus on managing capital turnover rather than technological breakthroughs, the industry gradually falls into a vicious cycle.

Notably, systemic risks are accumulating. WM Motor's bankruptcy left over RMB 20 billion in arrears owed to over 200 suppliers, directly causing battery manufacturer Tarfiel to drop out of the industry's top 15. NIO Automobile has accumulated over RMB 6 billion in arrears owed to 134 core suppliers. Bankruptcies of automakers like Leopard and Brilliance have also sparked supply chain bad debt issues. The collapse of any automaker could trigger a domino effect across the industrial chain.

In contrast, overseas experiences offer insights. Germany relies on strict 'Civil Code' provisions, mandating delayed payers to pay default interest at the 'benchmark interest rate + 8 percentage points,' forcing Volkswagen and BMW to compress payment periods to around 40 days and implement 'delivery upon pick-up.' Japan has established a symbiotic model, with Toyota and its suppliers forming a regular price negotiation mechanism to share costs. Denso's accounts receivable only account for 15% of its total, significantly lower than the 22% of its Chinese counterparts. While Tesla maintains a 90-day payment period, it provides supporting supply chain financial tools to reduce suppliers' financing pressure.

Industry experts believe that to break the deadlock, China urgently needs a systematic solution: At the legal level, clarify the starting point and payment form of the payment period, referencing Germany's punitive measures like financing restrictions and bidding qualification freezes for rigid constraints; abolish the consignment system and commercial bills in business processes; and financially, develop factoring of accounts receivable and asset securitization, establishing an 'OEM guarantee + low-interest financing for suppliers' channel to achieve transparent and efficient supply chain collaboration.

China's auto industry's clear '60-day payment' commitment signifies a significant shift in the automotive supply chain. The MIIT's latest announcement emphasized its importance in fostering a collaborative and mutually beneficial development ecosystem between 'complete vehicles and components,' promoting the industry's healthy and sustainable development, and will continue to guide automakers and supply chain enterprises to establish long-term and stable cooperative relationships, driving the integration, innovation, and collaborative development of large, medium, and small enterprises, actively creating a scenario where 'when the river is full, the creeks are also full.'

Typesetting | Yang Shuo

Image Source: Shutu Stock