Is Overcapacity a Global Phenomenon or Unique to China?

![]() 06/13 2025

06/13 2025

![]() 521

521

Only by transforming those rusted and idle production lines into vibrant productivity can we reemerge from the storm of excess capacity.

In June 2025, Li Shufu, Chairman of Geely Holding Group, made a bold statement under the spotlight that "the global automotive industry is facing severe overcapacity." This remark left hundreds of industry executives in the audience visibly perturbed.

Li Shufu's speech unveiled the most sensitive wound in the global industrial transformation.

"We will never build new factories again and refuse to repeat construction," Li Shufu declared, casting a ripple effect akin to a stone thrown into a still lake. Data reveals that the global automotive capacity utilization rate has dipped below the 65% warning line, with idle production lines in a joint venture factory in western China succumbing to rust. Against the backdrop of sluggish electrification progress in Europe and the United States, coupled with weak consumption in emerging markets, this strategic shift by the industry helmsman holds significant symbolism.

Chinese automakers are transitioning from a capacity race to a game of stockpiles.

Even more intriguing is the proposed "global capacity collaboration" solution: by integrating mature factories, sharing skilled workers, and reusing quality systems, the brutal zero-sum competition is transformed into a win-win ecosystem. This solution, imbued with Oriental wisdom, stands in stark contrast to news of Tesla's German factory halting production due to a labor shortage.

While the West grapples with union issues, Chinese automakers face the novel challenge of addressing overcapacity.

Extreme Differentiation in Utilization Rates

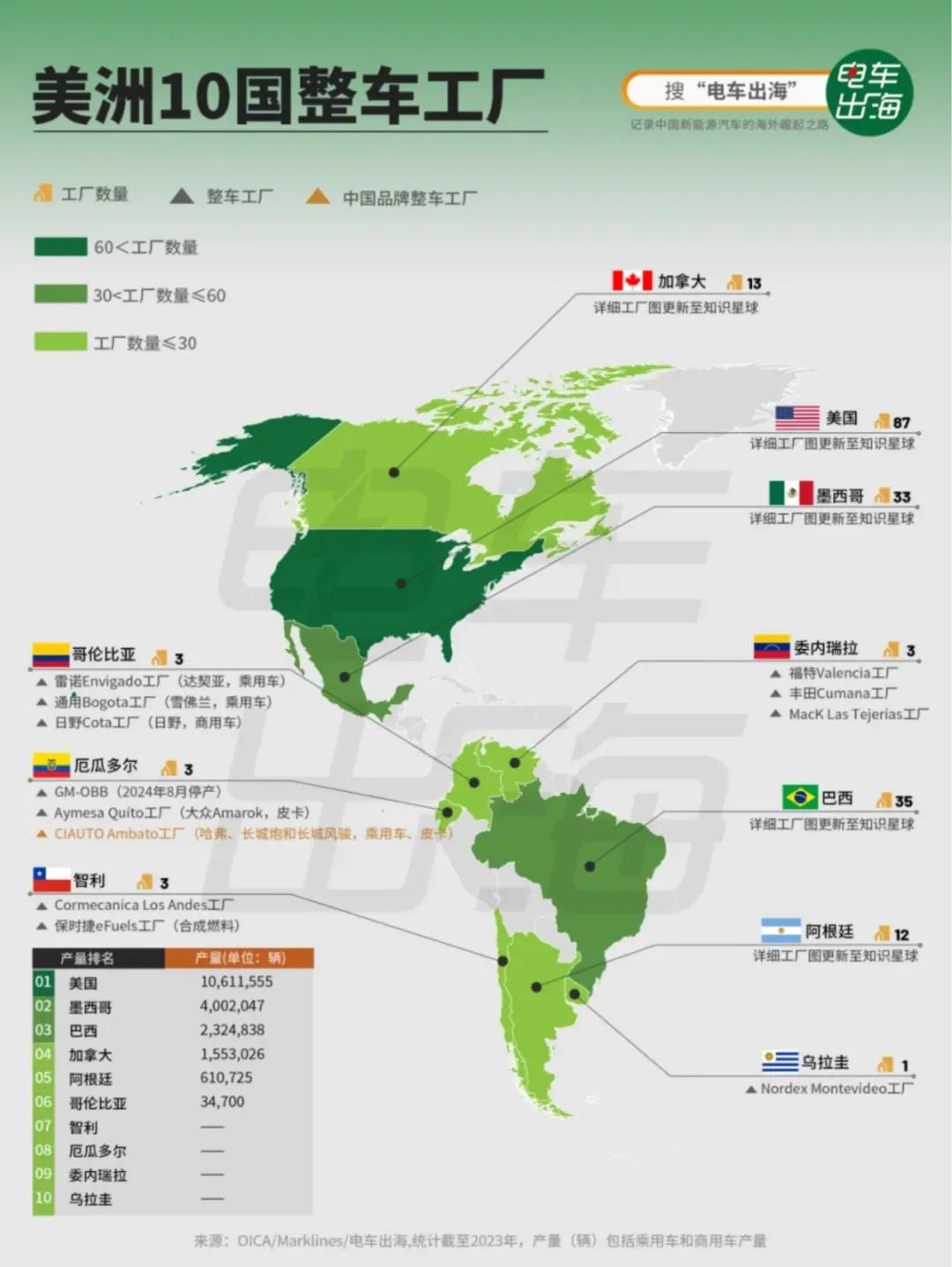

"Currently, China has at least 30 million units of fuel vehicle capacity and over 20 million units of new energy vehicle capacity already built. However, the transition from fuel to electric vehicles has only absorbed 2 million to 3 million units of fuel vehicle capacity, with most of the new energy vehicle capacity being newly constructed," pointed out Su Bo, former Vice Minister of the Ministry of Industry and Information Technology, at the China Electric Vehicle Hundred People Forum held on March 28.

For instance, BYD's capacity utilization rate has been above 99.5% for four years since 2021.

At its peak in 2023, the capacity utilization rate even reached 160%, with a capacity of 1.9 million units and a production volume of 3.034 million units (indicating that some production bases operated in double shifts). With the completion of multiple production bases, BYD's capacity utilization rate returned to 100% in 2024, with a capacity and production volume of 4.28 million units for the year.

Xiaomi's current capacity utilization rate is even close to 200%. If you order a Xiaomi car now, delivery will be approximately 6-7 months later, or even longer. Lei Jun, founder of Xiaomi Group, stated that capacity expansion is imminent.

It is worth noting, however, that the issue of overcapacity has spilled over into the realm of new energy passenger vehicles.

As market competition intensifies and the capital market experiences a winter, the new energy market has embarked on a new wave of bankruptcies. In 2023 alone, crossover automakers such as WM Motor, Aiways, Enovate, BAONENG, and Evergrande successively encountered financial difficulties, all of which had self-built factories. As of the end of last year, the combined annual production capacity of these five automakers was approximately 720,000 units, but actual production was less than 10,000 units. These idle new energy factories are also facing closure or conversion.

Of course, this is merely the tip of the iceberg when it comes to idle capacity in the new energy vehicle industry.

A more pressing issue is that, according to Goldman Sachs data, the capacity utilization rate of China's fuel vehicle factories will decline from 54% this year to 48% by 2030, while the capacity utilization rate of electric vehicles will increase from 58% this year to approximately 80% by the late 2030s. As a result, with fuel vehicle production and sales volumes, as well as profitability, declining sharply, a substantial amount of capacity remains unused, facing a major existential crisis. Some enterprises have already ceased operations and shut down.

In 2024, the issue of overcapacity was most acute for the Japanese-Korean and American factions. As of now, the capacity utilization rate of Japanese-Korean brands has plummeted from 74% in 2017 to 45%. Among them, the capacity utilization rate of Korean brands has declined the fastest. The production capacity of the two Korean brands, Beijing Hyundai and Kia, in China is nearly 2 million units, but the estimated production volume for this year is less than 300,000 units, with a utilization rate of less than 20%. To improve operating conditions, the two Korean brands have begun to shift to exports.

The situation for Japanese brands has also become less optimistic. In the past few years, due to relatively cautious and conservative planning, Japanese brands maintained a high capacity utilization rate in China. From 2017 to 2021, along with the increase in fuel vehicle production and sales, the capacity of Japanese brands was basically at full capacity. However, in the past two years, under the impact of new energy, their market share of fuel vehicles has continued to shrink.

Even though the situation is slightly better, it benefits more from the high capacity utilization of the three luxury brands, Mercedes-Benz, BMW, and Audi. The overall decline in capacity utilization of European brands in China is relatively manageable and still ranks first among all factions.

For some Chinese brands, they are cutting fuel vehicle capacity or addressing the overcapacity crisis by exporting overseas.

Gong Min, head of research on the Chinese automotive industry at UBS, told the media that from 2020 to 2024, the capacity utilization rate of Chinese brands climbed from 65% to 84%. During the same period, the capacity utilization rate of foreign brands fell from 73% to 56%, and it is estimated that 10 million units of redundant capacity need to be cut.

Analysts believe that the growth of export business is more pronounced in terms of capacity enhancement for traditional independent brands, rising from about 30% in 2023 to about 46% this year. Among them, Chinese brands such as Chery, BYD, and SAIC Motor, which have achieved strong growth in export sales, have benefited the most, offsetting the negative impact of sluggish domestic fuel vehicle sales. For example, SAIC Motor was able to maintain sales of 5 million units in 2023, with its overseas market contributing a quarter.

However, analysts warn that currently, the growth rate of export sales cannot keep pace with the overseas capacity expansion by automakers. As some automakers' overseas factories are completed and come online, the growth rate of trade exports will continue to slow down. This means that the contribution of exports to solving the domestic overcapacity problem is temporary and limited.

"Overcapacity is inherently linked to blind expansion and market competition," and it is challenging to eradicate overcapacity as long as there is competition. From the perspectives of both governments and automakers, to minimize the problem of overcapacity, it is essential to plan capacity reasonably and revitalize existing idle capacity through contract manufacturing, mergers and acquisitions, and other means, striving to improve capacity utilization.

A Tale of Two Cities

Industry standards generally consider a capacity utilization rate of 70%-80% to be within a healthy range, with anything below 70% potentially indicating excess capacity. However, the primary reasons ultimately stem from sluggish global economic growth and weak demand.

Dr. Stefan Hartung, Chairman of the Board of Directors of the Bosch Group, stated that the world is facing a problem of sluggish demand for automobiles, with global automobile production declining from 94 million units to 93 million units. In particular, the popularization of future technologies such as electric mobility, fuel cells, and assisted driving is much slower than industry expectations, and the speed of adoption of these technologies varies greatly across different markets.

Both the European and North American automotive markets are grappling with the dilemma of declining demand for traditional fuel vehicles and slower-than-expected adoption of new energy vehicles. U.S. sales in 2024 were 15.9 million units, and EU sales in 2024 were approximately 12.84 million units, both lower than their 2019 sales levels.

The decline in sales corresponds directly to overcapacity.

Taking the United States as an example, the capacity utilization rate of its automotive factories will decline significantly over the next decade. S&P Global Mobility predicts that the capacity utilization rate of North American automotive assembly plants will fall from approximately 72% in 2024 to approximately 63% by 2030. Michael Robinet, Executive Director of Global Automotive Business at the research institution, said, "I am very concerned that by 2035, the capacity utilization rate of automotive factories may drop significantly."

But this is an unchangeable fact.

According to GlobalData's forecast, starting from 2025, the average capacity utilization rate of North American automotive factories will decline again, falling to 65% by 2030 and 63% by 2035. GlobalData stated that by 2035, the market share of electric vehicles in North America may exceed 50%. As of last May, the market share of electric vehicles in North America was only about 7%.

Jeff Schuster, Global Vice President of Automotive Research at GlobalData, said that it is inefficient for automakers to operate with a capacity utilization rate of less than two-thirds. In the coming years, the average capacity utilization rate of North American automotive factories may not be able to maintain a level of at least 70%.

"The slowdown in the transition to electric vehicles has hindered the improvement of automotive factory capacity utilization rates. Automakers need to maintain flexibility, producing both internal combustion engine-powered vehicles and pure electric vehicles, as well as all products in between, which leads to inefficiencies," Jeff Schuster believes.

According to GlobalData's predictions, by 2030, the capacity utilization rates of Honda, Hyundai Motor America, Mercedes-Benz, Toyota, and the Volkswagen Group will be at least 70%. The capacity utilization rates of General Motors, Ford, BMW Group, and Renault-Nissan-Mitsubishi Group are expected to be below 66%.

Similar to the domestic situation, if the capacity utilization rate of automotive factories declines in the coming years, it will also adversely affect parts suppliers.

Michael Robinet noted that suppliers who provide to underutilized factories will face significant risks. "If a supplier participates in a pure electric vehicle project, but the sales volume of the project's products falls short of expectations, then they will face difficulties."

Based on this, multiple international automakers have announced plans to close factories and lay off employees.

Facing a sudden drop in profits, Nissan launched the "Re:Nissan" plan, which will close seven factories and lay off 20,000 employees by 2027, reducing capacity from 3.5 million units to 2.5 million units. This move is seen as an upgraded version of the "Ghosn Era Revival Plan" – in 1999, Nissan achieved a turnaround by laying off 21,000 employees and closing five factories, but the current scale of layoffs and capacity reduction has doubled, highlighting the severity of the situation.

Due to the difficult economic environment, the Volkswagen Group has already informed employees in 2024 of its plans to close at least three of its ten German factories, lay off tens of thousands of employees, and scale down the size of all its remaining factories in Germany. This marks the first time Volkswagen has closed a factory in Germany since its establishment in 1926.

For the Chinese market, although the capacity utilization rate has declined since the second half of 2018, the overall situation remains relatively manageable. According to data from the National Bureau of Statistics, in the first quarter of this year, the capacity utilization rate of China's automobile manufacturing industry was 71.9%, a recovery of approximately 7 percentage points compared to 64.87% in the same period last year.

From Henry Ford's creation of the assembly line, which initiated a worship of capacity, to Li Shufu's announcement of "never building new factories," the automotive industry's hundred-year cycle faces the ultimate question of how to transition from "bigger and stronger" to "lighter and more integrated."

After all, only by transforming those rusted and idle production lines into vibrant productivity can we emerge reinvigorated from this storm of excess capacity.

Note: Some images are sourced from the internet. If there is any infringement, please contact us for removal.