Indian-made iPhones: A New Frontier Stirring Up Indian Debate!

![]() 04/27 2025

04/27 2025

![]() 462

462

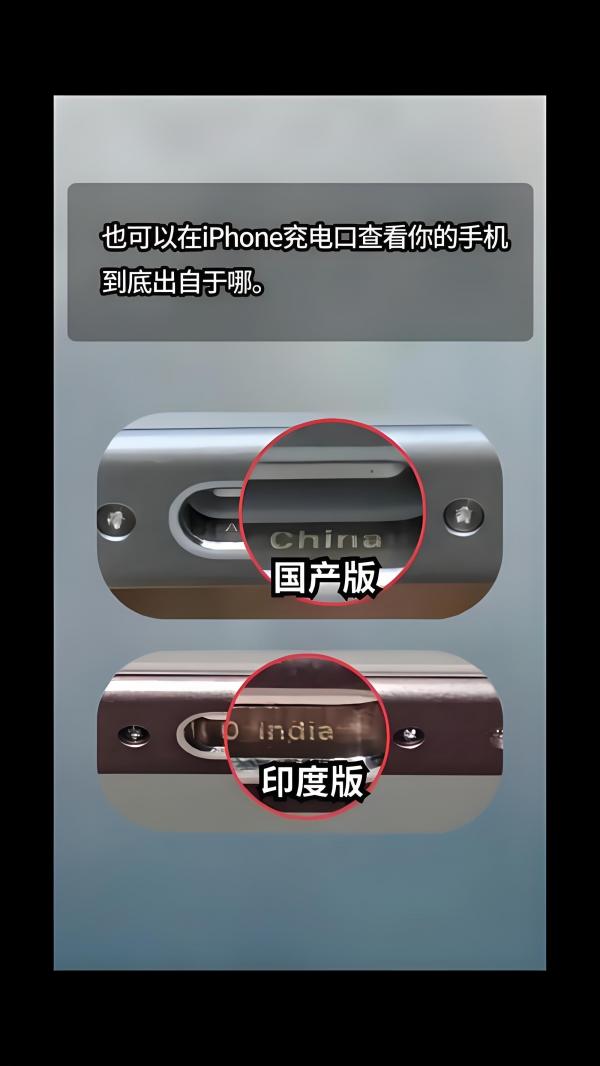

The label 'Made in India' on iPhones signifies a grand narrative of technological globalization versus localization. Apple has made a significant push into the Indian market by relocating some iPhone production lines, aiming to replicate the success of 'Made in China'. However, this seemingly beneficial 'South Asian venture' has posed challenges for Cook and his team, including quality disputes and supply chain inefficiencies.

Behind the production of Indian-made iPhones lies Apple's strategic blueprint. Amidst global trade uncertainties, Apple seeks to mitigate risks by diversifying its supply chain. India, with its vast population and burgeoning middle class, naturally caught Apple's eye. However, the reality is that component pass rates in Indian factories have garnered attention. Foreign media reports indicate a pass rate of around 50%, meaning half of the phones require rework. This data is a significant setback for Apple, which strives for 'zero defects'.

Quality issues directly impact consumer experience. Users have reported flaws in key components like cameras and screens on Indian-made iPhones. Some found fingerprints inside the camera upon unboxing, while others complained about glue seepage from screen edges. While these issues don't hinder phone functionality, they significantly erode consumer trust and satisfaction with the Apple brand.

Instead of avoiding these quality disputes, Apple has actively taken steps to enhance the quality of Indian-made iPhones. It has increased investment in Indian factories, introducing advanced production equipment and technology. Additionally, Apple has deployed experienced engineers from China and other regions to provide hands-on training and guidance. Despite these efforts, quality issues persist.

Moreover, Indian-made iPhones grapple with supply chain challenges. Indian factories remain heavily reliant on imported components, with 70% sourced from China and other locations. This elevates production costs and exposes them to international supply chain fluctuations. India's local supply chain system is still nascent, unable to meet Apple's stringent quality and efficiency standards.

Undeterred by challenges, Apple persists in its Indian market strategy. It continues to invest, aiming to establish India as a key iPhone production hub. For Apple, India represents both a vast consumer market and a strategic pivot. Through India, Apple aims to bolster its influence in South and Southeast Asia, fortifying its global footprint.

Consumers, however, prioritize quality and price. Currently, Indian-made iPhones lack a significant price advantage over Chinese-made counterparts. Quality issues have further eroded consumer trust. Hence, Apple must not only improve quality but also devise pricing strategies to attract more buyers.

The Indian iPhone venture is in its nascent stages, beset by quality disputes and supply chain inefficiencies. Apple must deploy greater effort and ingenuity to navigate these challenges. Consumers, too, must maintain a rational and objective stance, recognizing Indian-made iPhones' potential while being mindful of existing issues. Only then can we collectively propel Indian-made iPhones towards a brighter future.