Airtightness Testing: The Unseen Force Propelling the Advancement of New Energy Vehicles

![]() 06/12 2025

06/12 2025

![]() 505

505

Produced by Zhineng Technology

Amidst the relentless pursuit of quality and the escalation of high-end manufacturing standards, the significance of airtightness testing has surged.

Established in 2008, Xianri Measurement & Control has been a pioneer in this domain, achieving groundbreaking advancements in vacuum and airtight testing technologies. Notably, with the proliferation of new energy vehicles and their stringent sealing performance requirements, Xianri's technology has emerged as a cornerstone for enhancing product reliability and safety.

At the EAC2025 Yitrade Auto Industry Conference and Exhibition, we engaged with Li Xiaohua, Marketing Director of Shanghai Xianri Measurement & Control Technology Co., Ltd. It became evident that the company is not merely expanding within the domestic market but also leveraging China's manufacturing globalization trend to broaden its international clientele and establish a robust local service network. This exemplifies an equipment enterprise that holds core technologies and is steadfastly advancing towards the global market amidst the manufacturing industry's evolution.

01

What Distinguishes Xianri Measurement & Control's Helium Leak Detection?

Airtightness testing is a vital technical aspect in industrial manufacturing, widely utilized to assess product sealing performance, thereby enhancing safety and durability.

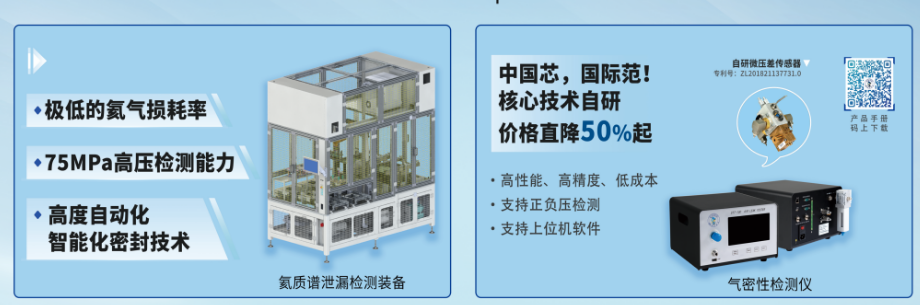

Since its inception, Xianri Measurement & Control has centered its focus on this technical arena, gradually developing a comprehensive R&D and engineering system. The company's helium leak detection equipment and airtightness testing instruments boast high precision, multi-functionality, low energy consumption, and easy integration, making them indispensable in new energy vehicles, batteries, air conditioners, medical equipment, and other sectors.

◎ In high-pressure testing, sealing technology has traditionally been a formidable challenge. Xianri has overcome this hurdle through a patented structure that balances airtight sealing with pressure isolation, ensuring the safety testing of high-pressure complex components. Currently, the company supports high-pressure helium detection up to 75 MPa, positioning it at the forefront globally.

◎ Given helium's premium cost as a tracer gas in leak detection, Xianri has achieved a technical equilibrium in detection sensitivity and stability, offering clear technical benchmarks for helium consumption control. These consumption metrics can be quantified and even incorporated into customer technical agreements, effectively reducing long-term usage costs and enhancing the equipment's value.

◎ Beyond helium detection, Xianri Measurement & Control has introduced the Leak Detection Fairy series of high-precision differential pressure-based intelligent gas leak detectors to cater to diverse sealing test applications. With fully self-developed core components and independent intellectual property rights, this product rivals international brands in performance parameters, embodying a truly Chinese chip with global appeal. It surpasses cost and supply chain constraints, offering exceptional cost-effectiveness.

02

New Energy Vehicle Sealing Demands Spur Application Upgrades, Making Helium Detection Crucial for Quality Assurance

With the rapid growth of new energy vehicles, the sealing requirements for electric drive systems, thermal management components, and power battery packages have soared, concurrently driving the demand for high-reliability testing equipment.

Particularly, as the battery system is the linchpin of new energy vehicle safety, any sealing failure during high-voltage charging and discharging could lead to thermal runaway, short circuits, and other safety hazards, necessitating continuous industry standard upgrades. In anticipation of the new national standard to be implemented in 2026, Xianri Measurement & Control has completed preliminary product standard preparations, and its current product line fully complies with the testing requirements outlined in the new specifications.

Currently, the company collaborates with numerous automakers and core component suppliers, spanning traditional automakers, luxury brands, and new entrants in the automotive industry. Key players in the global supply chain, including Bosch, United Automotive Electronic Systems, and Benteler, have integrated Xianri equipment into their critical testing stations. By penetrating the vehicle production system through Tier 1 customers, Xianri Measurement & Control's products and solutions have garnered recognition from an increasing number of automakers.

Over 70% of the company's orders now stem from enterprises associated with the new energy industry chain. Airtightness testing is evolving from its traditional role of "quality control" to "safety assurance + efficiency enhancement," becoming an indispensable intermediary process.

03

Following Chinese Manufacturing Globalization: The Globalization Strategy of Domestic Suppliers

Since 2016, Xianri Measurement & Control has expanded into overseas markets, serving customers in 12 countries and regions, primarily auto parts manufacturers. Some of its testing equipment is also utilized in general industrial scenarios like steel drums, refrigeration, and nuclear power, achieving domestic substitution in various applications.

This export growth is not fortuitous but aligns seamlessly with the globalization pace of China's automotive industry chain. As Chinese vehicle and supply chain enterprises accelerate their international expansion, Xianri, as a pivotal testing equipment supplier, accompanies its customers into markets such as Southeast Asia, Europe, North America, and the Middle East, marking the completion of its first phase of internationalization.

From supporting exports and technical assistance to local installation and debugging, the company's service model is continually expanding. Initially focused on equipment manufacturing, it is now evolving into a comprehensive service system encompassing "technical adaptation + local response."

Currently, Xianri is exploring ways to further optimize service radius and delivery cycles through local contract manufacturing and cooperative factory establishment. Navigating different national markets entails addressing varying regulatory certifications, standard systems, and customer operating methods. To this end, the company continuously deepens its understanding of regional market structures and tailors product design and testing processes to meet customers' specific needs, thereby enhancing engineering execution and after-sales support capabilities.

Compared to imported brands, Xianri Measurement & Control leverages its technical prowess, price structure, and service response capabilities to create a combined advantage. Under a 7×24-hour service response mechanism, remote diagnosis and preventive maintenance have become its distinct selling points. Amidst a small pool of influential testing equipment suppliers in overseas markets, Xianri is establishing its presence in multiple markets through continuous technological accumulation and reputation building.

Technological competition remains the paramount challenge ahead. In core application scenarios like helium detection, overseas enterprises still possess a robust technical foundation. However, through sustained investment in its R&D system, Xianri is deeply involved in scheme design during customers' early R&D stages, locking in technical pathways and product forms from the outset, gradually forging an independent technological moat. The detection structure and high-pressure control system based on independent patents are the cornerstones underpinning the company's steady growth.

The Industrial Role of Equipment Enterprises is Being Reshaped

High-end manufacturing is not an isolated system; the equipment technology and testing platforms behind it are the foundational supports ensuring quality, safety, and efficiency. Driven by the new energy wave, every link—from vehicles to components, thermal management to power systems—cannot advance without advancements in testing technology. Xianri Measurement & Control's role in this process transcends that of a mere "equipment manufacturer"; it is a behind-the-scenes fulcrum driving the manufacturing system's upgrade.

It is no easy feat for domestic high-end equipment to go global. It necessitates keeping pace with customers' internationalization efforts while also establishing a strong technological discourse. Xianri Measurement & Control's path demonstrates that rooting itself in domestic demand, grasping the evolution of industry standards, and exporting technology and services through the window period of manufacturing globalization are effective strategies for realizing equipment enterprises' global ambitions. Technology implementation, service closed-loops, and product upgrades constitute the core elements propelling China's equipment industry chain towards high-end status and global integration.

On this path of steady progress, Xianri Measurement & Control's value is not flamboyant but clear and potent.