The Protagonist of the AI Conference: Beyond Robots

![]() 07/31 2025

07/31 2025

![]() 429

429

Able to craft ice cream, brew coffee, play drums, dance, and even practice calligraphy, robots that seamlessly transition from the hall to the kitchen have emerged as a viral sensation at this year's World Artificial Intelligence Conference.

From a public perspective, these dazzling capabilities certainly captivate with their visual impact and promise of integration into daily life. However, delving into the core logic of economic development reveals another industry worthy of our attention: the Industrial Internet, which silently fortifies China's manufacturing sector from the supply side.

Supported by AI, this industry has undergone a transformational shift.

[Technological Leap]

AI's impact on the Industrial Internet is not gradual but revolutionary and disruptive.

Consider a simple example: data is the lifeblood of the Industrial Internet. In the past, manufacturing enterprises grappled with significant disruptions in data flow across various scenarios and business links, impeding efficient data circulation. Industrial Internet platforms struggled, akin to "cooking without rice," severely limiting their capabilities. Today, AI large models have exponentially enhanced these platforms' data connectivity, facilitating seamless data flow between vertical industrial control hierarchies and horizontal business scenarios, enabling the direct implementation of numerous advanced technologies.

Another illustration lies in data application. Previously, Industrial Internet platforms accumulated numerous industry-specific mechanism models, often in the form of isolated "experience fragments," which hindered their ability to transcend vertical field boundaries. This heavy reliance on specific domains made the platforms cumbersome in addressing the diverse realities of "thousands of enterprises, thousands of faces."

The scenario is now vastly different. Large models transform scattered industry know-how into transferable general knowledge graphs, which can be efficiently and cost-effectively replicated and applied across various fields.

At the AI conference, COSMOPlat unveiled the latest scientific and technological achievements of the Tianzhi Industrial Large Model, introducing the world's first trillion-level large model catering to the entire petrochemical industry chain, ecosystem chain, and value chain. Additionally, it presented the industry's first trillion-parameter energy and carbon large model, derived from sustainable lighthouse factory practices.

This move signifies a landmark turn for Industrial Internet platforms in the AI era, marking a definitive departure from the inefficient "one model for one scenario" approach of the past. If we envision Industrial Internet platforms as producers, they have transformed from handicraft workshops into modern assembly line factories.

It's also noteworthy that without AI, the pinnacle of digital transformation would merely be a highly automated and informatized mechanical entity. However, with AI, the production system acquires "anthropomorphic intelligence," capable of perception and thought. In the future, it may even replace or iterate human decision-making in certain domains, evolving from a mechanical body into an intelligent agent. This leap is monumental.

All these breakthroughs were unthinkable in the pre-AI era, collectively resulting in a visible surge in the technological capabilities of Industrial Internet platforms.

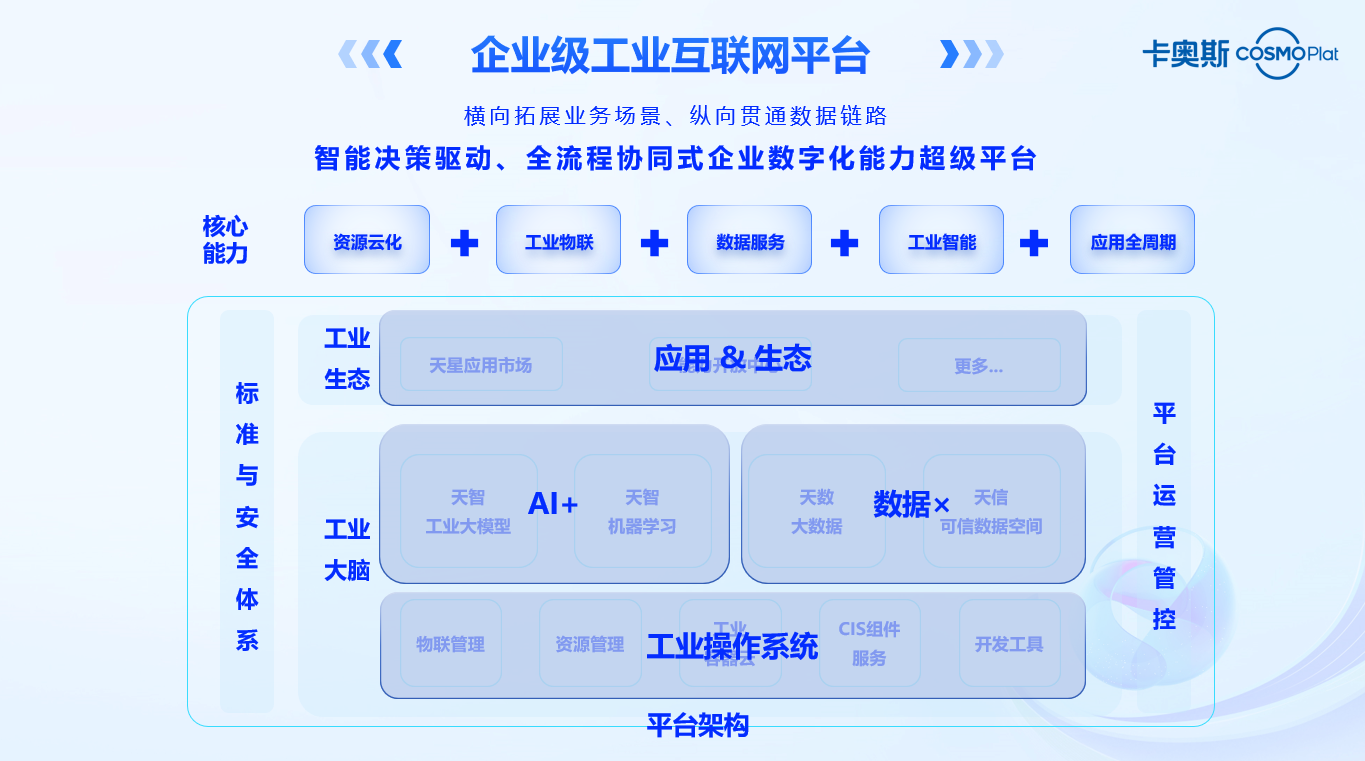

At this year's World Artificial Intelligence Conference, COSMOPlat showcased the industry's first five-star (intelligent) level certified Industrial Internet product—the enterprise-level Industrial Internet platform. This platform adopts a "1+N" modular architecture, where "1" represents the integrated main console base, and "N" signifies various modular plugins. Users can freely assemble a digital transformation platform akin to building blocks, catering not only to the diverse needs of different industries and enterprises of varying sizes but also to the individualized needs of personnel with different functional roles within the same enterprise. For instance, executives can view global data, workshop directors can monitor equipment efficiency, and finance departments can peruse cost reports...

Through this single product, one can intuitively perceive that Industrial Internet platforms have ascended to a higher level in terms of service breadth, depth, and granularity.

In fact, AI not only reshapes the technological architecture of the Industrial Internet but also radically accelerates its historical progression. Assuming that without AI, the Industrial Internet would take a decade to reach its peak, it might now achieve this milestone in just five years or less.

[Industry Acceleration]

For any technology industry to achieve substantial growth, it must fulfill two essential conditions: large-scale, low-cost supply and a substantial increase in product use value.

Let's reflect on the evolution of mobile phones. In the 1980s, when the "big brother" mobile phone first arrived in China, its price soared into the tens of thousands of yuan, equivalent to an ordinary worker's decade-long salary, and its functions were limited to instant communication. Under these circumstances, mobile phones could not achieve widespread adoption. Subsequently, MediaTek introduced the "turn-key" solution, integrating multiple chip types (such as audio, video decoding, and signal processing) into a single chip, significantly lowering production thresholds and costs, and dramatically increasing mobile phone penetration. Then, the iPhone ushered in the smartphone era, condensing almost every aspect of human life—clothing, food, housing, transportation, and entertainment—into a single device, priced affordably at around one month's salary, making early adoption accessible, leading to unprecedented growth in consumer electronics shipments.

The Industrial Internet follows a similar trajectory. In the past, digital services primarily focused on point-to-point breakthroughs and one-on-one engagements. This approach could not facilitate large-scale service provision, effectively reduce costs, or offer significant use value, thereby hindering substantial development.

AI fundamentally resolves this conundrum.

As mentioned, the Industrial Internet can now empower industries cost-effectively, efficiently, and on a large scale, fostering a self-iterating virtuous development cycle: "industry data accumulation → large model knowledge extraction → cross-industry empowerment → new data feedback." In the future, digital service costs will continue to decline, efficiency will soar, capabilities will strengthen, and coverage will broaden.

Even three years ago, Industrial Internet platforms offered limited digital services to enterprises, akin to early feature phones that could only make calls. Today, product diversity has skyrocketed. COSMOPlat has explored benchmark models in key areas such as discrete manufacturing (represented by the home appliance industry), process manufacturing (represented by the petrochemical industry), and green manufacturing (represented by zero-carbon parks). If interested, you can explore these models further; I won't delve into details here.

With robust capacity, expanded services, and reduced costs, only one question remains: does the use value provided by the Industrial Internet justify the investment, i.e., the economic benefits of enterprises undergoing digital transformation?

Imagine if an enterprise's digital transformation costs 1 million yuan and yields 500,000 yuan in benefits; the digitalization process would naturally stagnate. However, if the cost of industry digital transformation drops to 500,000 yuan and the potential value increases to 1 million yuan, enterprises will eagerly embrace it.

The Industrial Internet is currently accelerating in this direction.

Taking COSMOPlat, the industry leader, as an example, in the first half of this year, the company empowered Xinjin Group to achieve full-chain digital management and energy-saving efficiency improvements in its compressed air supply system. This project created an industry-leading "first-class energy efficiency air compression station" for Xinjin, saving 24.15 million yuan and reducing carbon emissions by over 26,000 tons over its lifecycle.

With the assistance of the world's first trillion-level energy and chemical large model for oil, gas, coal, chemicals, and electricity, jointly released by COSMOPlat and the China Petroleum and Chemical Industry Federation, Yanchang Petroleum constructed an exclusive large model covering six core scenarios, precipitating 38 scenario intelligent agents, directly boosting enterprise production efficiency by over 50% and reducing production costs by millions of yuan.

Saving millions or even tens of millions of costs instantaneously, such immediate economic benefits undoubtedly fuel enterprises' digital transformation drive with immense motivation and confidence.

If digital transformation was once considered a mere bonus, it may now become a lifeline. If it was once optional, it is increasingly becoming indispensable.

[Concentrated Value Realization]

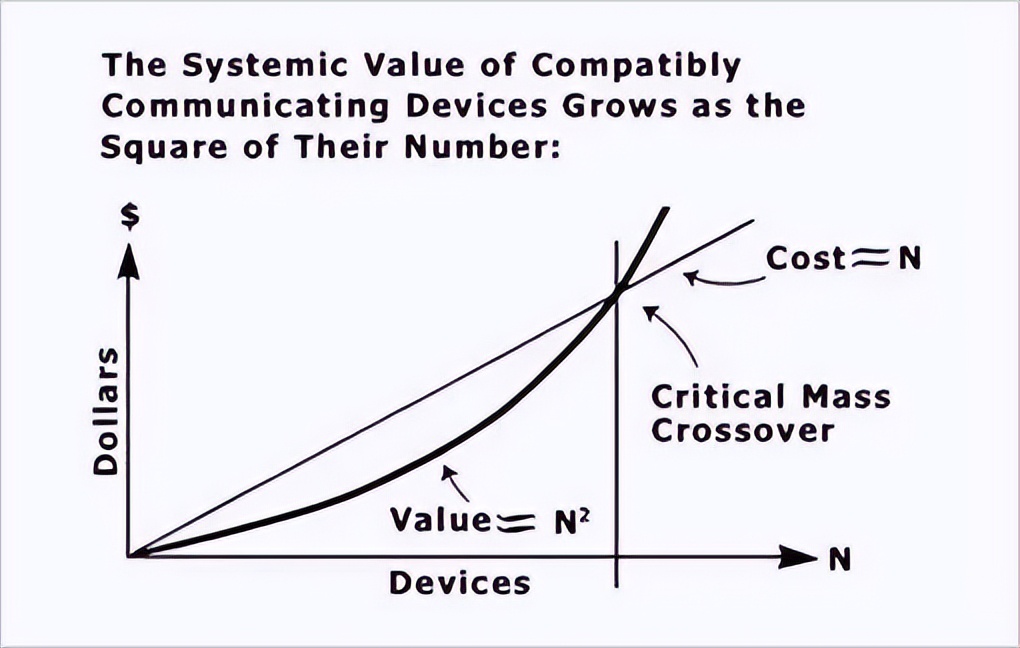

According to Metcalfe's Law, the value of a network is proportional to the square of the number of nodes in that network, implying that value increases exponentially with the growth in the number of access points.

The Industrial Internet shares similar attributes.

In recent years, despite significant foundational layout and strategic investments by the government and related enterprises in the development of the Industrial Internet, only a handful of enterprises initially embarked on isolated and fragmented digital transformations, leading to uneven digitalization levels across different industries and within the same industry.

Without interconnected digitalization, it's impossible to form a highly coordinated organic whole, and the full value of the Industrial Internet network cannot be realized.

The current scenario is vastly different. With the acceleration of commercialization, the Industrial Internet has gradually evolved from point-based development to area-based development. Consequently, network effects are gradually emerging, propelling the industry into a period of concentrated value realization.

The value of the Industrial Internet mentioned here is its potential to propel China's manufacturing sector upwards.

Previously, COSMOPlat empowered Ruihua Group to build flexible production capabilities for "small orders with quick response," enabling the latter to secure numerous high-value small orders that it could not previously handle. The dual increase in order volume and product added value significantly boosted the company's profitability.

In a recent practice, COSMOPlat successfully assisted Tianyi Medical in creating a fully unmanned intelligent factory, doubling annual production capacity with the same workforce while increasing on-time order delivery rates by 25%.

While the digital transformation of individual entities can enhance benefits, the potential unleashed when all stakeholders in the industrial chain are integrated is even more promising.

China is the world's largest manufacturing country, and the manufacturing sector forms our most crucial foundation, influencing national strategies and livelihood projects such as employment and taxation; it is also the core economic pillar. In the first half of 2025, China's GDP was approximately 66 trillion yuan, with the manufacturing sector's added value accounting for up to 25.7% of GDP.

If the Industrial Internet can drive a 1 percentage point increase in manufacturing output value annually through its efforts, it can contribute hundreds of billions of yuan to GDP. Once the Industrial Internet is deeply rooted and widespread across the manufacturing sector, Industrial Internet platforms will undoubtedly be the first to benefit.

Recent data indicates that the value proportion of platforms in the Industrial Internet industry is continuously increasing.

From 2021 to 2024, the average growth rate of China's overall Industrial Internet market was 13.6%, but the average growth rate of the Industrial Internet platform market was as high as 32.9%.

Among all Industrial Internet platforms, those like COSMOPlat will be the first to reap the benefits.

COSMOPlat has long ranked first among domestic dual-cross Industrial Internet platforms and is one of the few local enterprises leading and formulating international standards. The company proactively proposed the development concept of "large enterprises building together, small enterprises sharing" long ago. This approach did not yield immediate results and seemed somewhat thankless in the early stages but laid a solid foundation for long-term growth. Through this approach, COSMOPlat has cultivated a rich and vast ecosystem. Currently, the platform has created 12 lighthouse factories across industries, connected 900,000 enterprises worldwide, and served 160,000 enterprises.

From Metcalfe's Law's perspective, COSMOPlat is inherently a highly potential value creator. Although the company has already achieved a brand value exceeding 100 billion yuan, in the long run, this may only be the beginning.

Before reaching a truly great and prosperous moment, there will inevitably be years of seemingly insignificant progress.

Since the United States proposed the "Industrial Internet" and Germany introduced "Industry 4.0," the Industrial Internet has been evolving for over a decade. During this period, political, academic, and industrial circles have invested significant human, financial, and material resources. All these efforts and contributions will eventually be rewarded manifold at a pivotal juncture.

This represents the promising future of China's manufacturing sector and serves as a boundless expanse of stars and oceans for enterprises such as COSMOPlat.

Disclaimer

This article includes content pertaining to listed companies and is founded upon the author's personal analysis and judgment, which are derived from information disclosed by listed companies in compliance with their legal obligations (this includes, but is not limited to, interim announcements, periodic reports, and official interactive platforms). The information or opinions presented in this article do not constitute investment advice or any other form of business guidance. Market Value Observation assumes no liability for any actions taken as a consequence of utilizing this article.

——END——