Hikvision Unveils Innovations at South China Industrial Expo, Pioneering Industrial Digitization with Intelligent IoT

![]() 06/04 2025

06/04 2025

![]() 460

460

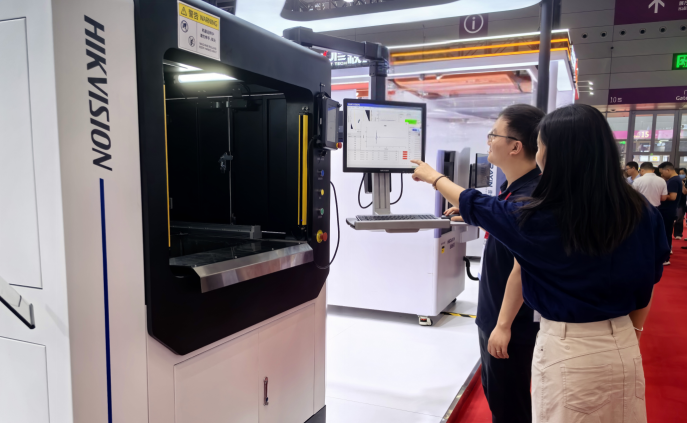

The 2025 South China International Industrial Expo, themed "Intelligent IoT Accelerates Digitization of Industrial Scenarios," took place from June 4-6 at the Shenzhen World Exhibition & Convention Center. Hikvision made its debut, showcasing digital solutions tailored for five key industrial scenarios: quality inspection, equipment management, safe production, production operation, and operational management. These exhibits demonstrated the innovative applications and tangible benefits of digitization in industrial settings.

AI Large Models Revolutionize Industrial Digitization

Large AI models significantly enhance perceptual and cognitive intelligence, effectively addressing pain points in industrial environments. At this year's Expo, Hikvision presented a range of digital products powered by its Guanlan large model, illustrating the transformative impact of these models on the industrial sector.

In the safe production area, visitors could scan a QR code and upload photos of potential hazards. The enterprise safe production management platform, bolstered by large model capabilities, swiftly identified these hazards, enabling on-site photo capture, remote inspection, and one-click intelligent inspection of operational risks.

Robotic and collaborative arms are reshaping production efficiency, yet safety precautions remain crucial. Hikvision's industrial safety camera series, leveraging large model technology and stereo vision imaging, accurately detects personnel in restricted areas. Detection signals can be linked to control systems like PLCs and safety relays, with minimal delay, effectively preventing mechanical collisions and ensuring safe production.

The vibration-resistant and anti-shake tube camera series, also enhanced by large models, intelligently identifies and warns against personnel intrusion in the movement path of large mechanical facilities, adhering to the principle of "no personnel during crane operation." Equipped with a hook-following visual algorithm and triple vibration-resistant scenario-based software and hardware design, this series provides operators with clear, stable images, enhancing operational safety and productivity.

In defect detection, large models enable more precise and efficient X-ray non-destructive testing. The exhibited X-Ray intelligent offline AXI inspection equipment, equipped with large model capabilities, precisely identifies minute defects in electronic components, achieving rapid operations like one-click bubble detection, with detection efficiency increased by over 80%.

Multiple New Products Ignite Digital Transformation in Industry

Based on deep insights and extensive experience in industrial scenarios, Hikvision continues to innovate, developing digital products tailored to industrial production and operation needs. This Expo saw the debut of several new Hikvision products, aimed at revitalizing and upgrading industries with digital power.

The molten pool observation camera is designed for precision welding and laser cladding quality control, overcoming challenges like strong light interference and splash damage. It captures high-definition images of the molten pool and integrates algorithms for AI analysis of key parameters, providing remote visual and data feedback to optimize processes.

For defect detection in precision parts in sectors like new energy vehicles and wind turbine manufacturing, the ultrasonic phased array automated inspection system performs "B-mode ultrasound" on parts, enabling non-destructive inspection through visual scanning and AI-driven internal defect assessment. Traditional methods often involve destructive sampling, damaging parts and yielding slow, unstable results with difficult traceability.

The liquid absorbance automatic analyzer uses spectral analysis to obtain liquid absorption spectra, detecting concentration and dye-up rate information during production, quantifying color differences, and ensuring product compliance. It's applicable to monitoring dye-up rates in textile dyeing vats and identifying fermentation tank/ink concentrations.

The fiber Bragg grating demodulator accurately captures changes in reflected light wavelength, diagnosing abnormalities like temperature, strain, and displacement. It supports various sensors, assisting in high-precision, multi-dimensional equipment monitoring, such as stress monitoring of wind turbine blades, temperature monitoring of high-voltage switchgear, and crane boom monitoring in ports.

Five Exhibition Areas Highlight Innovative Practices and Tangible Benefits

Across five exhibition areas—quality inspection, equipment management, production operation, safe production, and operational management—Hikvision showcased digital products tailored to different industrial scenarios, each with unique strengths, attracting significant attention from visitors.

In the quality inspection area, Hikvision displayed a range of inspection capabilities, from macro to micro and surface to interior, continuously advancing the intelligent and precise upgrading of industrial quality inspection. For instance, in food inspection and other areas requiring detailed item composition understanding, the gas chromatography-single quadrupole mass spectrometer enables component analysis, substance identification, and authentication. In electronics manufacturing, the ultra-depth-of-field 3D digital microscope achieves micrometer-level observation, measurement, and analysis, offering an ultra-fine image observation experience with a maximum magnification of 6000 times and imaging effects for 2D and 3D measurements. The hyperspectral pushbroom camera can be used in scenarios like color deviation analysis, material identification and sorting, and food and medicinal material grading.

In the equipment management area, visitors could lightly tap on a simulation device, and the online acoustic and image instrument would synchronously capture signals, visually displaying intangible discharges, making equipment discharges perceptible. The acoustic, vibration, and temperature monitoring system comprehensively monitors and collects equipment operation status data from multiple dimensions, combining intelligent analysis to promptly detect anomalies.

In the production operation area, the X-Ray intelligent parts counter demonstrated its prowess in counting parts on-site. For tiny, numerous electronic components, it counted tens of thousands of parts in just 8 seconds with 99.99% accuracy. The radar series products enhanced inventory efficiency in various scenarios, such as the warehouse scene inventory expert laser scanning imaging radar with 70,000 effective sampling points per second, constructing high-precision models and achieving 98% volume measurement accuracy. For high-speed, high-flow industrial silos, the millimeter-wave scanning imaging radar reduced scanning time from minutes to as fast as 10 seconds.

In the safe production area, the TDLAS laser gas telemetry instrument monitored methane gas leaks in real-time, with a minimum detection concentration of 50 ppm, enabling efficient and precise detection of trace gas leaks in the early stages of hidden dangers. A comprehensive range of industrial fire protection products monitored environmental hazards, preventing fires before they start and safeguarding safe production.

In the operational management area, the AR series cameras, combined with the AR real-scene map application platform, provided an immersive interactive experience. This solution can be used in industrial scenarios like production parks and workshops, offering a digital overview and enabling three-dimensional, efficient management.

At this year's Expo, Hikvision showcased its products and technological capabilities, emphasizing "Intelligent IoT Accelerates Digitization of Industrial Scenarios." A Hikvision representative noted that the industrial field encompasses thousands of sub-scenarios, each with unique challenges. Leveraging deep expertise in IoT sensing, AI, big data, and other technologies, Hikvision helps industrial users perceive and collect diverse data, realizing the digitization of the physical world and better solving specific industrial challenges, thereby enhancing quality, reducing costs, improving efficiency, and ensuring safety.