Counting Down Eight 'Star' Domain-Specific Embodied Intelligent Robots: Why Are They Expected to Lead in Commercialization?

![]() 06/19 2025

06/19 2025

![]() 555

555

In the market, domain-specific embodied intelligent robots have long completed their "thick accumulation" and are quietly exerting their "thin release." The Embodied Learning Community has counted down the eight industrial and commercial embodied intelligence enterprises with the highest industry attention, dissecting their "evolution" in embodied intelligence in detail. Through these eight enterprises, we restore the current commercialization and development potential of embodied intelligence.

Editor: Xu Linhao

The ultimate measure of embodied intelligent robots is "user-friendliness." This standard not only sets the lower limit of application but also constitutes the top-level design of embodied intelligent robots. "Scenario demands" have long highlighted this context, requiring absolutely stable operational capabilities and a focus on improving quality and efficiency. The integration of new productive forces is not about "looking cool" but about being "truly user-friendly."

From the current perspective, general-purpose embodied intelligent robots possess greater generalization capabilities, capable of completing non-standard process operations in complex environments, playing a pivotal role in solving automation processes. However, it must be acknowledged that this application capability is still being explored and has not yet achieved large-scale deployment. On the other hand, domain-specific embodied intelligent robots offer higher stability and collaboration consistency, effectively addressing scenario pain points and have been diligently working in industrial and commercial scenarios for years.

Domain-specific embodied intelligent robots have verified their commercial feasibility through "actual problem-solving capabilities," completed global commercial deployment by anchoring vertical domain needs, and established a positive cycle of "scenario landing - data accumulation - technological iteration - scenario extension," becoming a new type of productivity with closed-loop evolution capabilities.

In the current era of technological leapfrogging, domain-specific embodied intelligent robots are evolving based on their own technological accumulation and scenario insight. "It's like walking on the shoulders of giants, except that the giant is the past self," industry analyst Meng Meng remarked to the Embodied Learning Community.

Delving deeper, domain-specific embodied intelligent robot enterprises have long completed large-scale commercialization layouts, capable of understanding scenario languages and developing new solutions to address potential scenario pain points. Additionally, relying on past industrial chain integration, specialized robot enterprises have faster layouts, lower costs, and significantly improved iteration capabilities, not only leading in ecological positioning but also possessing sustained competitiveness.

Image source: Embodied Learning Community

In the market, domain-specific embodied intelligent robots have long completed their "thick accumulation" and are quietly exerting their "thin release." The Embodied Learning Community has counted down the eight industrial and commercial embodied intelligence enterprises with the highest industry attention, dissecting their "evolution" in embodied intelligence in detail. Through these eight enterprises, we restore the current commercialization and development potential of embodied intelligence.

Hikvision Robotics: "Hand, Eye, Foot" Collaboration, Expanding Application Boundaries

Hikvision Robotics, spun off from the leading smart IoT enterprise Hikvision, focuses on the research, development, and production of machine vision, full-scenario solutions, and mobile robot hardware. Hikvision mobile robots can handle logistics scenarios with ease and have been widely applied in the logistics and warehousing industry, automotive manufacturing, the photovoltaic industry, and the 3C electronics industry, engaging in material handling tasks.

Taking the practical case of Australian enterprise BOCINI as an example, it introduced Hikvision Robotics' bin-to-person solution, deploying bin robots (CTU) and comb workstations on-site, coupled with an intelligent management system and robot control system. This setup can automate order picking for 65,000 bins, effectively improving bin circulation efficiency and storage space utilization.

During years of deep cultivation in mobile robots, Hikvision Robotics independently developed the SLAM navigation algorithm, demonstrating high-precision obstacle avoidance capabilities even in complex dynamic environments. In the field of machine vision, the optical detection technology integrated with deep learning achieves a defect recognition accuracy rate of up to 99.9%. Based on past technological accumulation in the robotics field, in March of this year, Hikvision Robotics announced the "Hand, Eye, Foot" collaboration strategy, launching a new product business - articulated robots, which have been applied in automotive parts factories, metal processing industries, and the 3C electronics industry.

Currently, Hikvision Robotics is exploring the application of AI large models and developing force-controlled collaborative robots. In its continuous evolution, the advantages of specialized robots have gradually become clear. Relying on Hikvision's supply chain advantages, Hikvision Robotics' self-developed controllers and sensors have a hardware cost 30% lower than foreign brands, making them extremely cost-effective.

This demonstrates that specialized robots emerging from scenarios can not only hone cutting-edge technologies that more accurately address demands but also "reap" the benefits of their own supply chains, further driving terminal price competitiveness by reducing costs.

UAI Robot: Cluster Collaboration, Industrial Embodied Intelligence for Scalable Applications

Founded in 2017, UAI Robot specializes in the research, development, and application of industrial mobile robot technology. Its composite robots with both autonomous mobile and manipulative capabilities are widely used in semiconductor, energy inspection, and other scenarios, serving over 300 leading global customers.

Semiconductor wafer fabs have extremely high requirements for the stability and cleanliness of logistics robots due to their high production standards. UAI Robot's self-developed composite robots achieve "hand, eye, foot collaboration," controlling the accuracy of movement and docking cargo within 2 millimeters and strictly controlling the vibration value below 0.2g. Through visual algorithm training, the robots autonomously recognize equipment processes and human-computer interaction decisions, evolving from "single equipment" to "swarm intelligence." Currently, UAI Robot's robots are batch-applied in global leading wafer fabs, with multiple cases of 100+ robots collaborating in factories and a cumulative 4 million material docking operations without error.

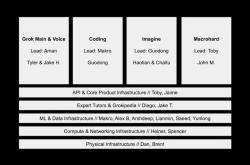

Based on deep scenario insight and years of technological accumulation, UAI Robot innovatively constructed the "One Brain, Multiple Morphologies" technical architecture, i.e., a set of robot intelligent systems controlling multiple specific robot morphologies, thereby achieving the ability to support the large-scale deployment application of different scenarios. "One Brain" refers to the highly generalized AI control system - MAIC (Mobile AI Comprehension), capable of multi-modal fusion perception, adaptive multi-arm collaborative operation, multi-morphology mobile control, and global logistics scheduling.

Image source: UAI Robot

Furthermore, the Embodied Intelligent Robotics Research Institute jointly established by UAI Robot and Xi'an Jiaotong University released the "Tianyan" series of seven humanoid robot plans. This builds a complete product system covering bipedal, wheeled, quadrupedal, tracked, and other morphologies, bringing intelligent transformation to complex industrial scenarios.

Among them, the first wheeled humanoid robot product, "Xunxiao," performs exceptionally well in semiconductor manufacturing workshops and energy industry distribution rooms, not only smoothly navigating through factories but also stably using tools for precise operations.

Relying on the "One Brain, Multiple Morphologies" architecture, UAI Robot's humanoid robots and composite robots can "share a brain," eliminating cognitive deviations between different robots, thereby achieving seamless collaboration. Domain-specific embodied intelligent robots complete relatively standardized workflows, while general-purpose embodied intelligent robots can handle non-standard tasks, outlining the close cooperation between "expert" and "general-purpose" productivity, further enhancing factory application efficiency.

UR Robot: Humanoid Robots with Straight-Knee Walking and Dexterous Manipulation Are Truly in Use

As the "first stock of collaborative robots," UR Robot's commercialization strength is self-evident. UR Robot starts from the manufacturing site, naturally possessing customer soil for "embodied intelligence landing," allowing AI models to be quickly imported and achieving large-scale rapid deployment. It not only has accumulated rich customer application scenarios and industry data but also possesses key technologies such as human-computer interaction, intelligent recognition, and operational control of embodied intelligent robots in industrial and commercial environments, which have been fully verified through large-scale applications in terms of the stable operation capability of robots in complex environments and the maturity of commercial landing.

This advantage allows it to occupy a leading position in the collaborative robot market. With the first full-size embodied intelligent humanoid robot Dobot Atom featuring "dexterous manipulation + straight-knee walking," it has ushered in a new stage of scenario-based applications for embodied intelligent humanoid robots. In industrial manufacturing, UR Robot has a deep customer base, including BYD, Mercedes-Benz, Porsche, Toyota, Microsoft, etc., to 200,000 users in small and medium-sized enterprises across a wide range of industrial manufacturing, with AI models quickly imported to achieve large-scale rapid deployment. In the service industry, UR Robot combines humanoid/wheeled platforms with multi-modal interaction to provide services in open environments.

Image source: UR Robot

It is understood that Dobot Atom breaks through the neural-driven dexterous operating system, enabling end-to-end autonomous reasoning and operation, equipping it with high-level motion control of upper and lower limbs and industrial-grade dual-arm collaborative high-precision operation capabilities, with a repeat positioning accuracy of up to 0.05mm.

In response to the refined upper limb operation requirements of most scenarios, Dobot Atom has strong task completion capabilities and operational performance. In a home environment, Dobot Atom can independently complete tasks such as making breakfast, pouring milk, arranging fruit platters, toasting bread, baking bacon, and arranging breakfast platters. In the corporate client reception link of commercial services, Dobot Atom can perform tasks such as pouring coffee, delivering documents, and picking up couriers.

The first batch of Dobot Atom deployments are in fields such as automotive manufacturing, electronics assembly, warehousing, and logistics. In these scenarios, Atom can act as a flexible "all-around worker" role: for example, on the production lines of automobiles or new energy batteries, it is responsible for assembling material handling, traveling between different stations, and connecting the gaps in assembly lines that are difficult for traditional fixed robotic arms to cover.

This mobile operation capability is precisely a powerful complement to traditional robotic arms provided by humanoid robots. UR Robot's collaborative robotic arms excel at fine assembly at single stations, while humanoid robots can flexibly move between multiple stations and operate multiple devices in tandem, achieving "one machine with multiple functions." The two complement each other, providing unprecedented flexible productivity for factories.

Before the release of Dobot Atom, in order to accelerate the faster entry of embodied intelligent robots into scenarios, UR Robot took the lead in releasing the embodied intelligent robot X-Trainer, which has been applied in multiple leading manufacturing enterprises, making it the first company in the global collaborative robot industry to commercialize AI-empowered collaborative robots.

Currently, UR Robot's various robots have been successfully applied in 15 major industries such as automotive, new energy, 3C electronics, metal processing, and home appliances, with over 80,000 deployments. In the 2024 performance report, UR Robot stated that in the future, it will adopt a dual-wheel drive strategy of collaborative robot intelligent upgrading + embodied intelligent robot innovation to create a next-generation embodied intelligent platform that is "software and hardware integrated, model-driven."

Qilang Intelligence: Insight into Scenario Demands, Prompting Development with Positioning

Since its establishment in 2010, Qilang Intelligence has been meticulously cultivating the field of dedicated embodied service robots and has released five series of products, including the service robot W3 series for hotel scenarios, the delivery robot T series for the catering sector, the disinfection and delivery X series for the medical field, the heavy-duty S series, and the cleaning robot C series. Currently, Qilang Intelligence's robot products have shipped over 100,000 units globally across more than 60 countries and regions, forming a mature industrial chain layout.

Among the vast array of product lines, delivery and cleaning robots stand out as Qilang Intelligence's flagship offerings, spearheading China's commercial service robots into the international market. Represented by the T series, these robots excel in service delivery scenarios, leveraging advanced navigation technology and obstacle avoidance systems to map out precise paths in complex environments and efficiently complete delivery tasks.

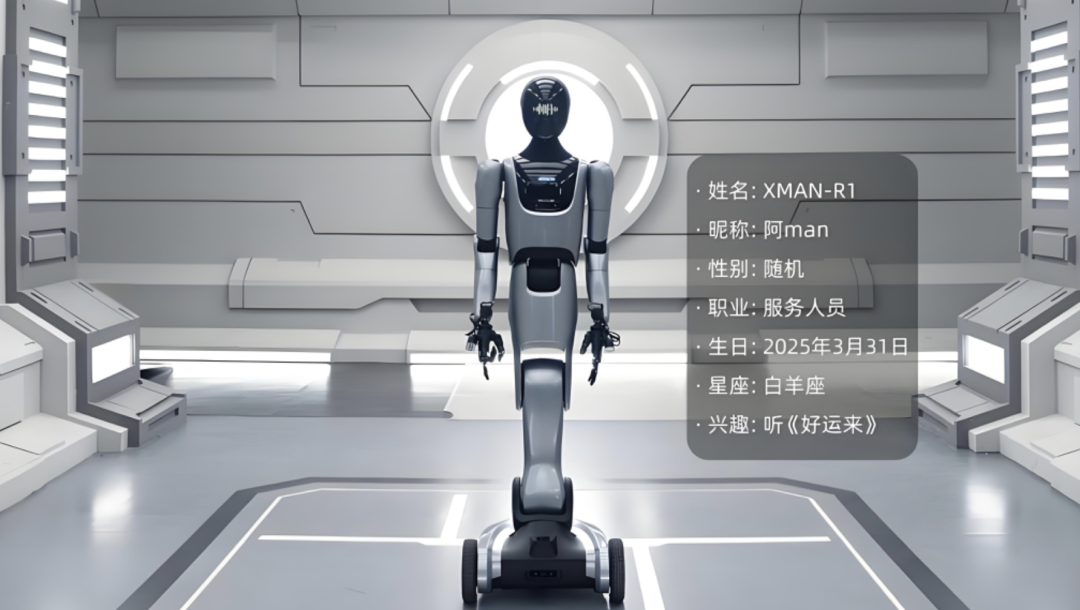

On March 31, Qilang Intelligence unveiled its maiden humanoid robot, XMAN-R1, embodying the concepts of "positioning, affinity, and safety." Positioned as a humanoid service robot "tailor-made for service," XMAN-R1 has successfully completed the entire service loop of "ordering, meal preparation, meal delivery, and meal collection."

Image source: Qilang Intelligence

In restaurants, XMAN-R1 independently performs tasks such as fetching wine, pouring wine, and placing trays. Through inter-machine task scheduling, it seamlessly hands over meals to the T10 delivery robot for optimal path delivery, ultimately completing table cleaning tasks. As such, XMAN-R1 has become a pivotal component in Qilang Intelligence's service robot ecosystem.

Addressing the challenge of elevator control in overseas hotel settings, Qilang Intelligence's dual-arm embodied service robot, XMAN-W3, integrates cloud-based multimodal large models for long-range task planning and complex scenario understanding, complemented by a "cerebellum" for trajectory planning and safe interaction. With bilateral mechanical arms, it performs tasks like pressing elevator buttons and handling items, adapting to more intricate service scenarios.

In hotel environments, the XMAN series collaborates with heavy-duty delivery robots like S100 and cleaning robots such as C40 to provide a suite of services, including greeting, luggage delivery, and commercial cleaning.

Through years of in-depth scenario penetration and data accumulation, Qilang Intelligence has not only achieved a leap in technological capabilities but also constructed an intelligent matrix catering to all scenarios. It holds a prominent position in unstructured environments like hotels, restaurants, and hospitals. This deep industrialization experience provides real-world testing grounds and demand coordinates for the iterative advancement of robot technology.

Kinova Robotics: Empowering with Dual Arms, Entering the Market with an Upstream Posture

Since its inception in 2014, Kinova Robotics has focused on the innovative R&D of new-generation collaborative robot arms and smart factories. It has established a comprehensive and efficient full industrial chain "flexible intelligence+" service system, offering one-stop solutions from R&D, production to after-sales for global enterprises across industries such as manufacturing, retail, and logistics.

Kinova Robotics has subsidiaries in Germany and Japan, with its star products sold in numerous countries and regions in Europe, Asia, and the Americas. Over 10,000 robots are deployed on the production lines of leading global customers in the automotive, electronics, and precision manufacturing sectors, including Schneider Electric, Toyota, Flextronics, and Dongshan Precision. These robots are used in hundreds of applications, including loading and unloading, locking, picking and placing, handling, palletizing, grinding, and welding.

In the realm of embodied intelligence, Kinova Robotics emphasizes the "upstream." For instance, the JAKA K-1 humanoid robot provides other companies with humanoid robot dual-arm solutions, software, and hardware support, while also being deployed in straightforward industrial scenarios like handling and sorting. This product has found applications in various laboratories and academic institutions, supporting the exploration of multiple scenarios.

Moreover, JAKA Robotics plans to explore unmanned delivery applications in park buildings, communities, and other settings, launching unmanned vending robots for high-traffic areas like railway stations, airports, supermarkets, and hotels. Several renowned brands, such as Master Kong, have started trialing JAKA robots in theme experience pavilions.

The cornerstone of its "upstream" position is the JAKA Lumi Embodied Intelligence Platform, featuring "efficient data collection + model training + parameter tuning + model deployment." The platform integrates a 12-DOF coordinated motion system, an intelligent lifting module, and multimodal sensors, and can be equipped with multiple JAKA+ brand dexterous hands and other end-effectors on demand, thereby constructing a comprehensive tool chain for embodied intelligence.

The most apparent advantage of this platform is its pricing at RMB 79,800. Thanks to JAKA's over a decade of expertise in integrated drive and control joints, it can enter the market at a competitive price, serving as a "catalyst" for new developmental changes.

Pudu Robotics: Comprehensive Layout in Three Forms, Evolving Around Scenarios

Starting with specialized robots, Pudu Robotics targets commercial service scenarios. It is one of the few robot manufacturers with a full matrix of "specialized, humanoid-like, and humanoid" robots. Its robot products are widely used in restaurants, hospitals, schools, office buildings, government halls, internet cafes, KTVs, airports, subway stations, and other domestic and international settings.

Specialized Robots: Taking Pudu Robotics' classic products as an example, the "Happy Delivery" food delivery robot is specifically designed for food delivery tasks in catering scenarios. It can accurately avoid obstacles and plan optimal paths in complex restaurant environments to ensure efficient food delivery. Pudu Robotics has been implemented in nearly 60 countries and regions worldwide, including Japan, South Korea, Singapore, and Europe. In the catering industry, it has been introduced to renowned enterprises such as Haidilao, XiBei YouMian Village, BaNu Beef Tripe Hot Pot, and BaHeLi Seafood Hot Pot.

Humanoid-Like Robots: On March 31, Pudu Robotics launched the world's first commercial scenario humanoid-like embodied intelligent service robot, Arm. Developed by Pudu's innovation laboratory, Pudu X-Lab, this robot can tackle diverse tasks across various commercial scenarios like hotels, buildings, catering, retail, and healthcare.

Humanoid Robots: In 2024, Pudu Robotics released its first full-size bipedal humanoid robot, PUDU D9. It can perform tasks such as parts assembly, material handling, and quality inspection in industrial production, adapting to various complex industrial environments and task requirements.

Achieving a "comprehensive flowering" of forms is rooted in the early-stage specialized robots' deep understanding of scenarios. This approach follows a proven logic of leveraging mature commercial scenarios rather than "seeking problems for solutions."

Dreame Tech: Robotic Vacuum Cleaners Don't Grow Hands, They Grow Imagination

As a leading player in the household robot industry, Dreame Tech excels not only in technology, having built a technological moat with high-speed digital motors, intelligent algorithms, and motion control technology, but also in its comprehensive layout of smart home appliances, including robotic vacuum cleaners, cordless vacuum cleaners, and smart floor washers. Its frequent appearances on major e-commerce sales charts underscore its robust commercialization capabilities.

Amid the embodied intelligence trend, leveraging its technological accumulation and deep understanding of scenario pain points, Dreame Tech has researched a novel species based on specialized robots: a robotic vacuum cleaner with arms.

On the software front, the embodied intelligence model endows the robotic vacuum cleaner with autonomous decision-making capabilities, enabling it to perform spatial logic-based classification and placement, and autonomously plan and organize paths through deep learning and environmental perception.

On the hardware front, the bionic multi-joint manipulator boasts five degrees of freedom and a reach of up to 33 centimeters, capable of gripping objects with a width of about 6 centimeters and a weight of up to 500 grams. The two camera systems recognize all objects on the ground, while the RGBD camera on the gripper coordinates with the host's binocular system, allowing the manipulator to pinpoint the grasping point and ensure smooth grasping. The manipulator also features a separate accessory warehouse with items like vacuum cleaners and sponge brushes, enabling it to autonomously retrieve and install accessories based on scenario/dirt conditions.

In summary, this smarter robotic vacuum cleaner, equipped with an extra hand, can seamlessly navigate around the home, cleaning floors, handling scattered debris, and organizing it. This transformation elevates the robotic vacuum cleaner from a single-plane cleaner to a 3D space cleaner, covering the entire home and fulfilling the role of a "household maid."

This product not only serves as a scenario verification for embodied intelligence products but also reveals a pivotal path for embodied intelligence development: When end-effectors and cognitive intelligence achieve deep coupling, the capabilities of household service robots will continue to expand into three-dimensional space.

DJI: A Hidden Embodied Intelligence Dark Horse, with a Focus on Technology Empowerment

DJI is a global leader in the research and manufacture of unmanned aerial vehicle (UAV) control systems and drone solutions. It dominates the consumer, professional, and industrial drone markets, accounting for approximately 70%-85% of the global drone market share.

DJI has accumulated core technologies in autonomous flight control, environmental perception, AI target detection, and more in the drone field. The essence of drones lies in being "aerial robots," and the core technologies they possess, such as obstacle avoidance, not only benefit their subsequent layout in embodied intelligence but also empower other enterprises, quietly fostering "technology spillovers."

Although DJI has yet to enter the embodied intelligence robot market, it has made substantial investments in autonomous driving, considered the "precursor to embodied intelligence." Currently, DJI's automotive business deeply permeates the entire chain of intelligent driving scenarios. Its launched intelligent driving business brand, "Zhuoyu," centered on pure vision technology, caters to the diverse needs of structured roads like highways, urban expressways, and parking lots. Through the "Oil and Electricity Intelligence" strategy, "Zhuoyu" has established collaborations with nine mainstream automakers.

From this perspective, DJI has established a collaborative system for embodied intelligence technology spanning air and land through its two core businesses: drones and autonomous driving.